Linear transfer system

LS ONE

With LS One, users rely on a subsystem based on the plug & work motto. It can be flexibly configured and easily commissioned.

features At a glance

- Cycle rate up to

70 cycles - Payload up to

5 kg - Process forces up to

300 N

- Stable design

- High-quality control cabinets are available

- Handling components can be integrated without a substructure

- Standard – mounting plates of 660 x 485 x 25 mm,

optionally with customer's hole pattern

- Freely programmable position, acceleration, speed and movement direction

- Forward and reverse movements are possible

- Positioning accuracy of ± 0.05 mm in the x-direction and ± 0.03 mm in the y- and z-directions

- Short transport times

- Process forces up to 300 N without additional support

- Loading up to 2 kg (weight of workpiece + its holders)

- Customer-supplied plates with a max. length up to 200 mm

- Optionally with RFID transponder

- Hardware capable of multiple voltages (400/480 V 3ph / 50/60 Hz)

- Fieldbus interfaces for customer interface:

Profinet, Ethernet/IP, EtherCAT - Frequency converter with integrated restart interlock Safe Torque Off (SIL 3, PL "e"), no SLS, no SOP

- 60% shorter transport times

- More processes in less space

- Tried-and-tested linear motor drive

CONFIGURATIONS

LS ONE

Depending on the final product, there are different machining, assembly and production processes. WEISS designs and builds your LS One for the number of processing stations in accordance with your requirements.

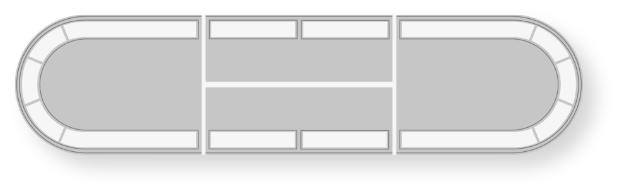

Small

Assembly processes can be automated with just one module on a footprint of 2.2 m x 0.9 m.

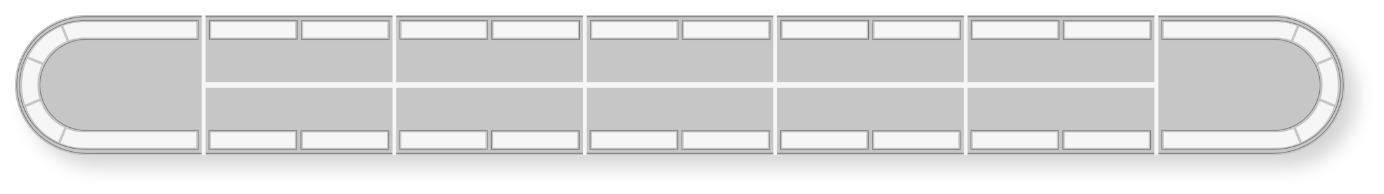

Medium

Most assembly automation processes can be replicated on medium-sized linear transfer

systems. For LS One, a size of 4.8 m x 0.9 m is suitable.

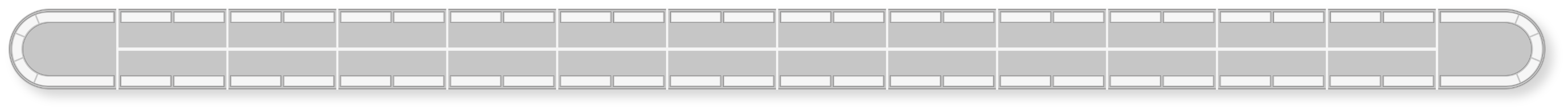

X-Large

For elaborate assembly processes with a lot of processing stations, LS One

can be expanded to up to 12 modules and thus reach a length of 9.5 m.

SPECIFICATIONS

LS ONE

Overview of the performance data and technical values of LS One.

- Cycle rate up to 70 cycles per minute

- Payload up to 5 kg per workpiece carrier

- Process force without support up to 300 N per process station

- Positioning accuracy ± 0.03 mm in y- & z- axis

- Transfer time for example

100 mm 0.20 s500 mm 0.40 s1000 mm 0.60 s

with optimized payload - Linear motor module

± 0.03 mm (x-axis)± 0.03 mm (y- & z-axis)

positioning accuracy - Fieldbus interface

PROFINETEtherNet/IPEtherCAT

Safe MotionSTO (SIL2, PLd) - Multi-voltage supply

200 - 480 V / 50 - 60 Hz

ControllingW.A.S. incl. remote maintenance