Linear transfer system

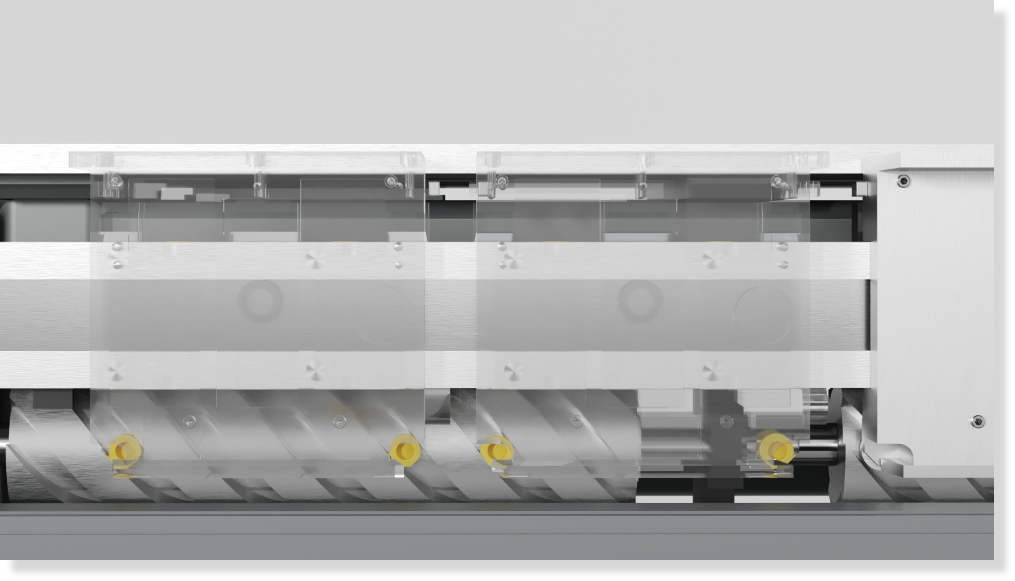

LS HYBRID

When process steps with different requirements for speed and cycle time are in the same sequence, the LS Hybrid is the right automation solution. Here, users can implement different processing, assembly and production tasks on one platform in a fully automated process.

features At a glance

- Cycle rate up to

60 cycles - Payload up to

10 kg - Process forces up to

1000 N

- Payload up to 10 kg (weight of workpiece + its holders)

- Absolute locking without indexing

- Process forces up to 1000 N without support

- Standard – carrier plates of 200 x 160 mm to a max. of 250 x 235 mm, optionally with customer's hole pattern

- Optionally with RFID transponder

- Positioning accuracy of ± 0.03 mm in x-, y- and z-directions

- Strokes: 64, 128, 256, 384, 512 mm

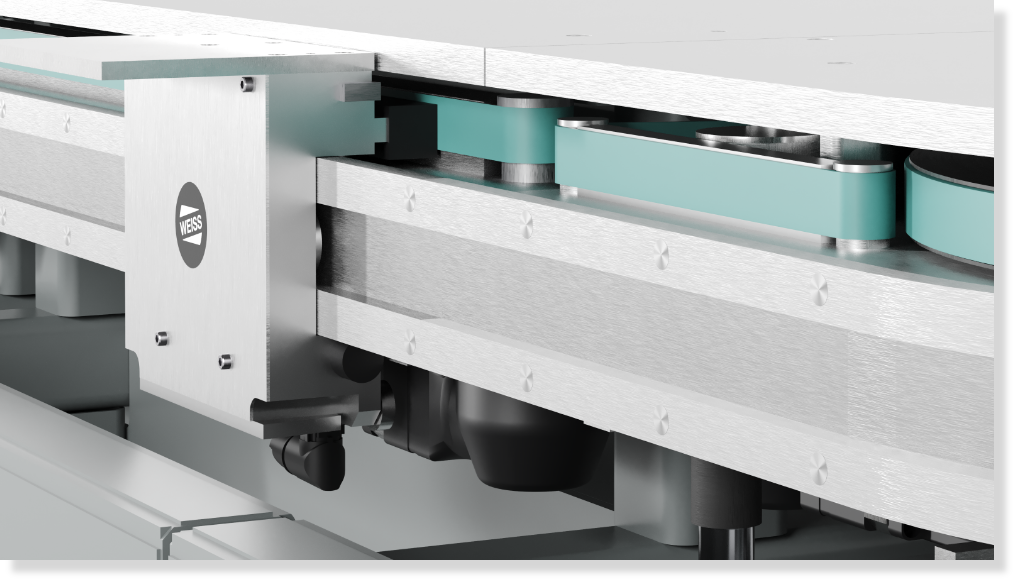

- Short transport times

- Up to nine eCAMs can be connected in series in one drive module

- Freely programmable position, acceleration, speed and movement direction

- Positioning accuracy ± 0.02 mm (x-direction)

± 0.03 mm (y- and z-directions) - Short transport times

- Forward and reverse movements are possible

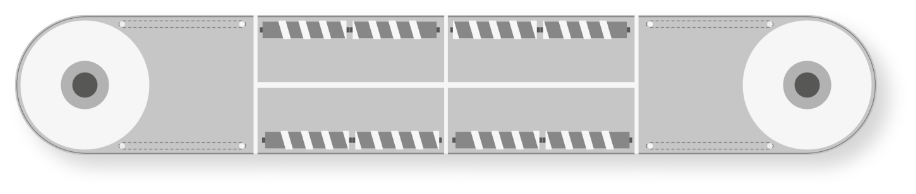

- Single-belt (1 x 1150 mm) or double-belt module (2 x 575 mm) available

- Positioning accuracy of ± 0.15 mm in the x-direction and ± 0.03 mm in the y- and z-directions

- Stop position in the center of the belt is possible

- Consists of 3 belts, redirection belt and infeed belt and outfeed belt

- Smoothly moves into/out of the straight transport modules

- 1 stop position at 90° is possible, positioning accuracy of ± 0.15 mm in the x-direction and ± 0.03 mm in the y- and z-directions

- Stable design

- Handling components can be integrated without a substructure

- High-quality control cabinets are available

- Standard – mounting plates of 1150 x 294 x 20 or 1150 x 590 x 20 mm, optionally with customer's hole pattern

- 20% higher cycle rates

- 40% shorter transport times

- High process capability

- More processes in less space

- Reliable components

- Hardware capable of multiple voltages (400/480 V 3ph / 50/60 Hz)

- Fieldbus interfaces for customer interface:

Profinet, Ethernet/IP, EtherCAT - Frequency converter with integrated restart interlock Safe Torque Off (SIL 3, PL "e"), no SLS, no SOP

CONFIGURATIONS

LS HYBRID

The assembly process differs depending on the final product. WEISS designs and builds your LS Hybrid in accordance with your requirements, drawing from the following combination options.

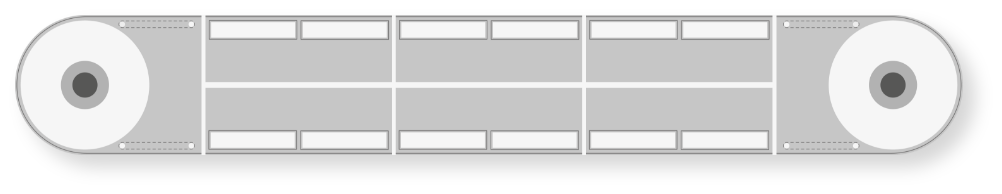

Precise positioning

LS Hybrid with 2 eCam modules on each side. For application

requirements with uniform clocking accompanied by maximum precision

and dynamics.

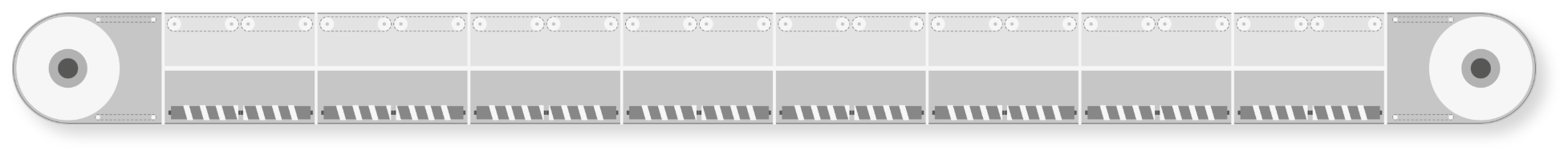

Fast reverse travel

LS Hybrid with 8 eCam modules on one side for application

requirements with uniform clocking accompanied by maximum precision

and dynamics. 8 belt modules on the opposite side enable fast reverse

travel.

Maximum flexibility and dynamics

LS Hybrid with 3 linear motor modules on each side, for freely definable

positioning and process patterns as well as motion profiles with high

accuracy requirements and cycle rates.

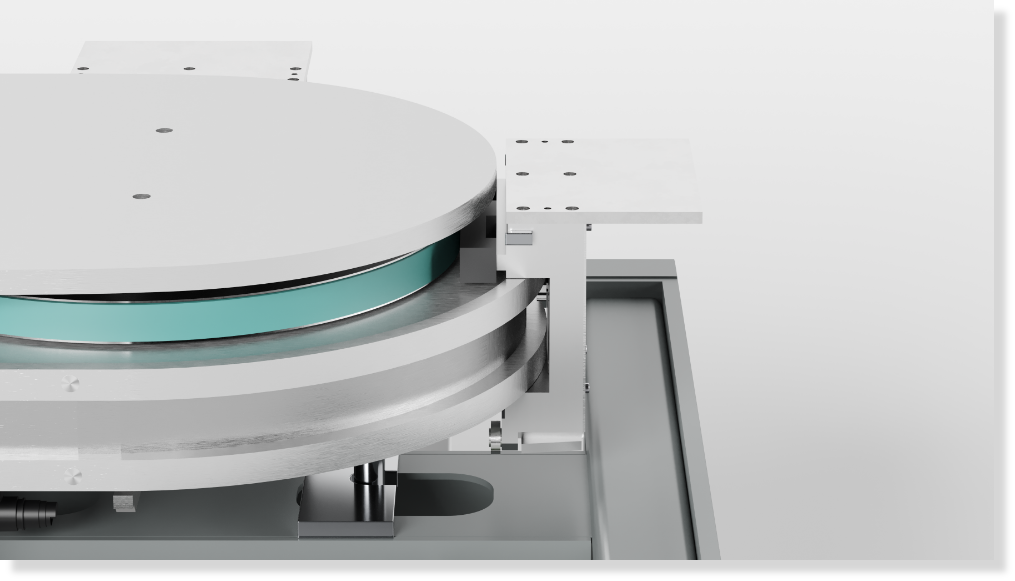

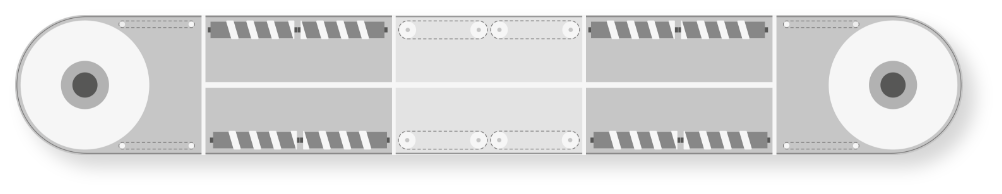

Rotary indexing tables without interlinking

LS Hybrid with 2 eCam modules on each side, each decoupled by 1

double-belt module for transport between the process stations.

Combination of securely locked process positions using different strokes

with maximum precision in each position.

SPECIFICATIONS

LS HYBRID

Overview of the performance data and technical values of LS Hybrid.

- Cycle rate up to 60 cycles per minute

- Payload up to 10 kg per workpiece carrier

- Process force without support up to 1000 N per process station

- Positioning accuracy ± 0.03 mm in x- , y- & z- axis

- eCam module

64 mm 0.25 s128 mm 0.30 s256 mm 0.40 s512 mm 0.90 swith optimized payload - Linear motor module

± 0.01 mm (x-axis)± 0.03 mm (y- & z-axis)

Belt / Corner module± 0.15 mm (x-axis)

positioning accuracy - Fieldbus interface

PROFINETEtherNet/IPEtherCAT

Safe MotionSTO (SIL3, PLe) - Technical availability

> 95 %Multi-voltage supply200 - 480 V / 50 - 60 HzControllingW.A.S. incl. remote maintenance