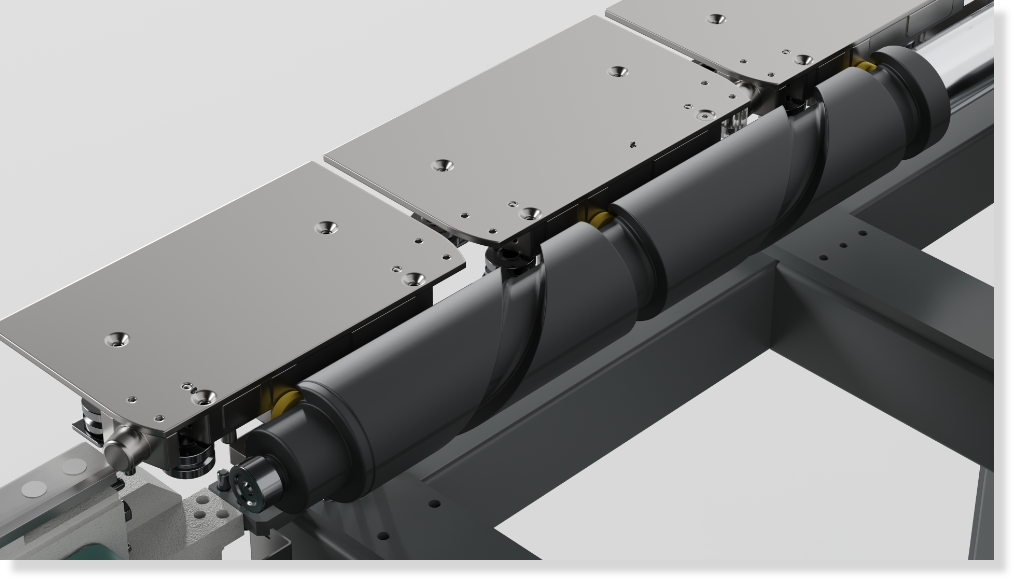

Linear transfer system

LS280

With LS280, WEISS has transferred benefits of the Rotary Indexing Table over to a Transfer System. This concept shortens the transport times and thereby increases the productivity. The modularly designed system can be expanded as needed.

features At a glance

- Cycle rate up to

40 cycles - Payload up to

4 kg - Process forces up to

300 N

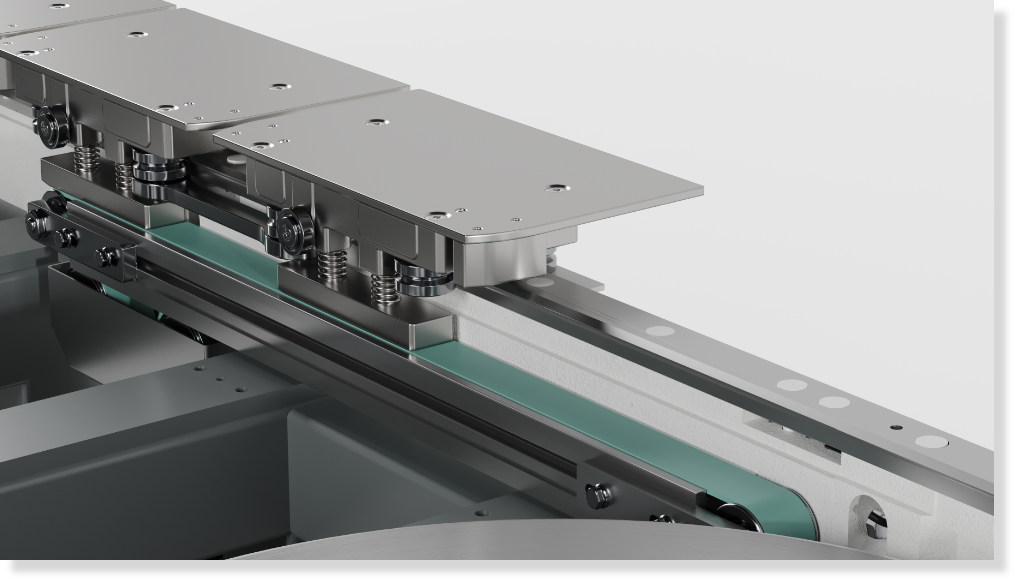

- Positioning accuracy of ± 0.03 mm in the x- and y-directions and ± 0.06 mm in the z-direction

- Different strokes (70, 140, 280, 560 mm)

- Short transport times

- Available as a single or double locking station

- Up to 28 locking stations on one LS 280 are possible

- Available in different lengths and transport speeds

- Workpiece also accessible from underneath

- Loading up to 4 kg (weight of workpiece + its holders)

- Stationary support of the carrier plates is possible at high process forces

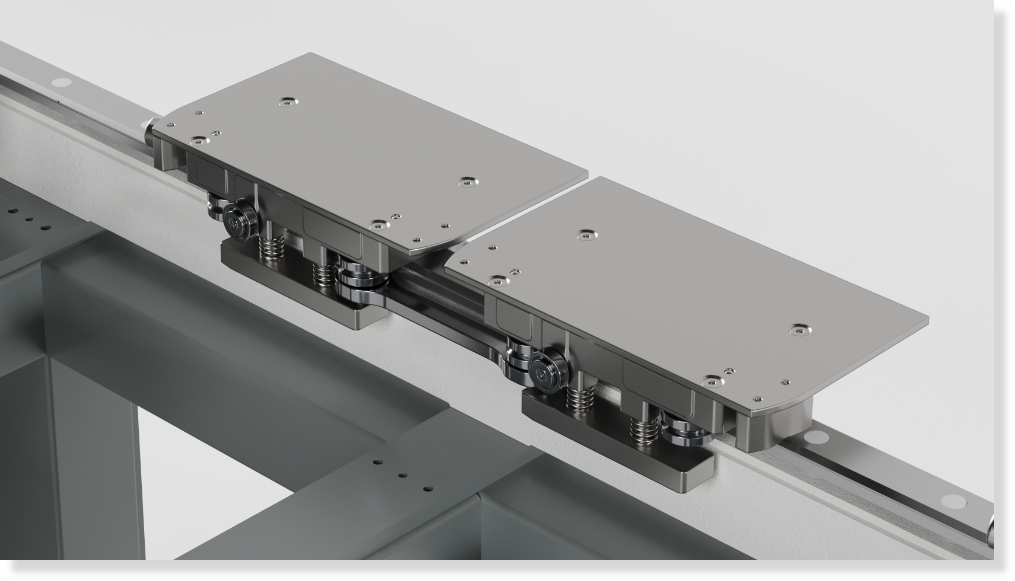

- Standardized carrier plates available in three sizes, optionally with customer's hole pattern

- Optionally with RFID transponder

- Stable design

- Handling components can be integrated without a substructure

- Central lubrication unit is optional

- Standardized carrier plates available in three sizes, optionally with customer's hole pattern

- Standard mounting plates are 1199 x 320 mm and 1199 x 480 mm, optionally with customer's hole pattern

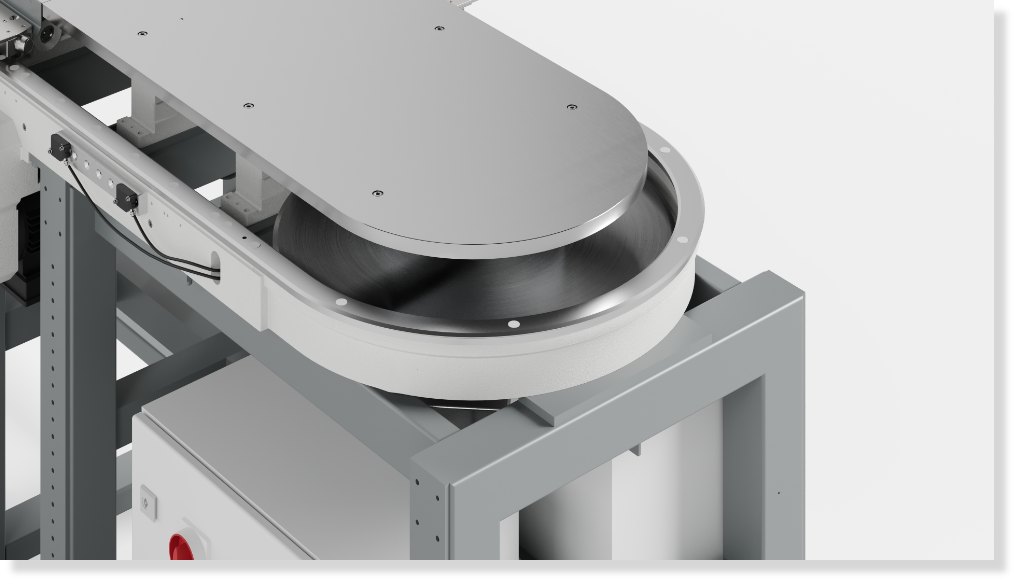

- Available in two versions

- 180° redirection module for a linear design

- 90° redirection module so that the face ends can have process stations attached

- Higher cycle rate increases the output

- Simple, reliable motion principle

- Workpiece carrier transport optimized for low level of jerking and jolting

- Compensates for different process times

- Highly reliable thanks to maintenance-free operation

- One master PLC per LS280 base machine

- Centrally stored parameter file

- Fieldbus interfaces for customer interface:

Profinet/Profibus, EtherNet/IP, EtherCAT - Hardware capable of multiple voltages (400/480 V 3ph / 50/60 Hz)

- Frequency converter with integrated restart interlock Safe Torque Off (SIL 2, PL "d")

CONFIGURATIONS

LS280

Depending on the final product, there are different machining, assembly and production processes. WEISS designs and builds your LS280 in accordance with your requirements, drawing from numerous combination options.

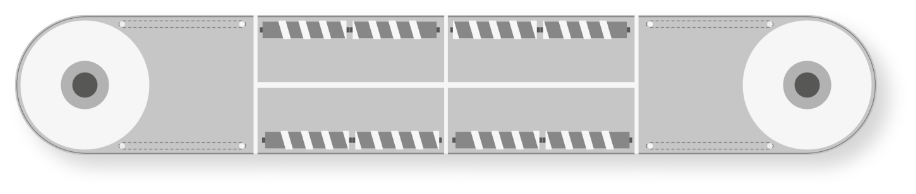

Double twin

The platform needs an area of only 4.8 by 9 m and offers the user a total of 21 workpiece positions (14 + 7). In this example, the cycle strokes used are at 140 and 280 mm.

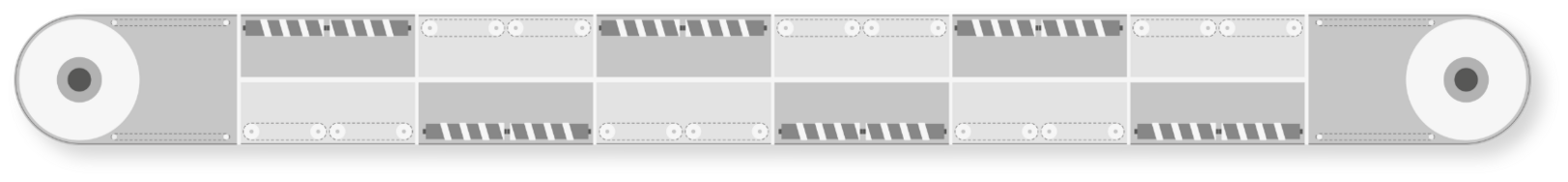

Offset arrangement

This version has a total of 29 workpiece positions in an offset arrangement. Cycle strokes of 70, 140, and 280 mm can be implemented here. The space requirement of this LS280 version is 9.6 x 0.9 m. Due to the offset arrangement, there is more space for potential attachments.

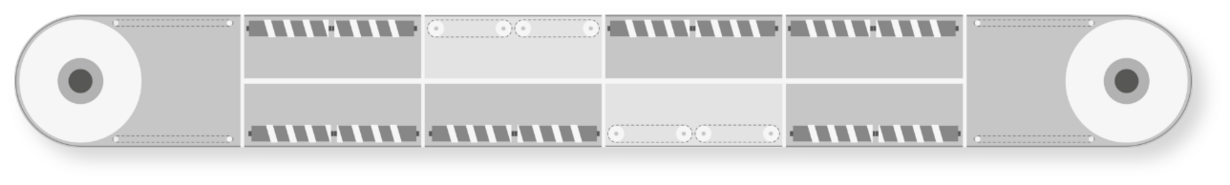

Offset twin arrangement

With a total of 13 workpiece positions, the LS280 twin version can also

be used in an offset arrangement. The width of the subsystem remains

at 0.9 m. The length is 7.2 m. The cycle strokes are 280 and 560 mm.

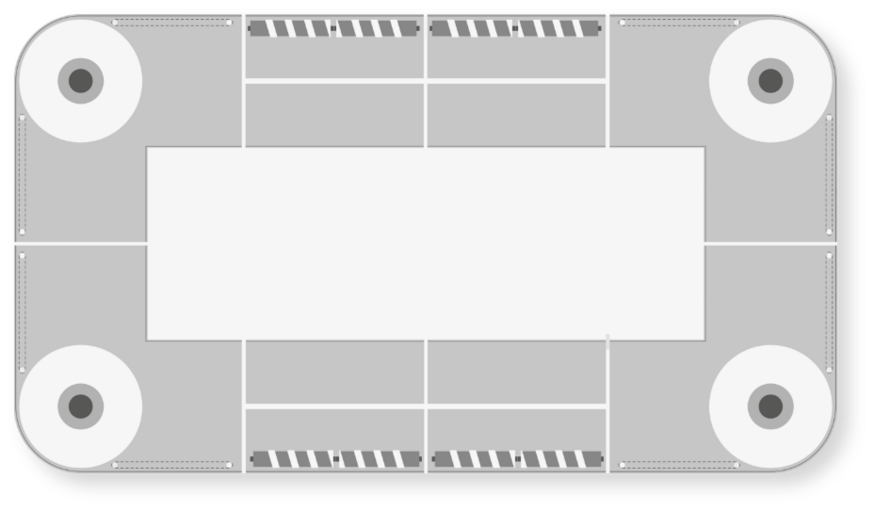

90° arrangement

This arrangement allows for processing stations to be implemented at the redirection modules. The footprint of this LS version is 4.5 x 2.5 m. It is designed with a cycle stroke of 280 mm and offers a total of 14 workpiece positions.

SPECIFICATIONS

LS280

Overview of the performance data and technical values of LS280.

- Cycle rate up to 40 cycles per minute

- Payload up to 4 kg per workpiece carrier

- Process force without support up to 300 N per process station

- Positioning accuracy

± 0.03 mm (x- & y- axis)± 0.06 mm (z- axis) - Indexing station

70 mm 0.40 s140 mm 0.50 s280 mm 0.60 s560 mm 1.20 s

with optimized payload

Transfer time down to - Belt / Corner module

600 mm 0.9 - 1.9 s1200 mm 1.8 - 3.8 s1500 mm 2.2 - 4.7 s1800 mm 2.6 - 5.7 s2400 mm 3.5 - 7.6 sTransfer time down to - Fieldbus interface

PROFINET / PROFIBUSEtherNet/IPEtherCATSafe MotionSTO (SIL2, PLd) - Technical availability

> 99 %Multi-voltage supply200 - 480 V / 50 - 60 HzControllingW.A.S. incl. remote maintenance