Hide Filter

Self Care isn't selfish. WHAT ARE YOUR NEEDS?

Max. Load LowMediumHigh

Cycle Rate LowMediumHigh

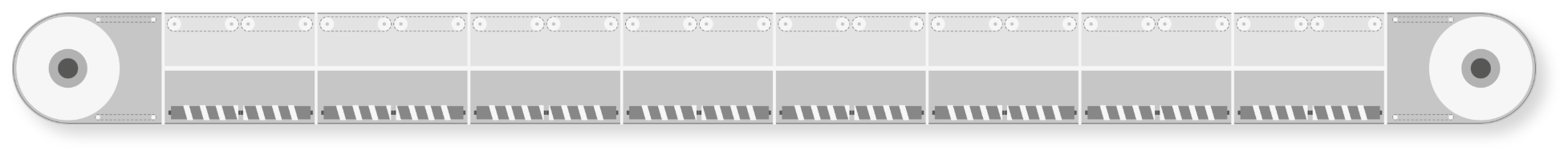

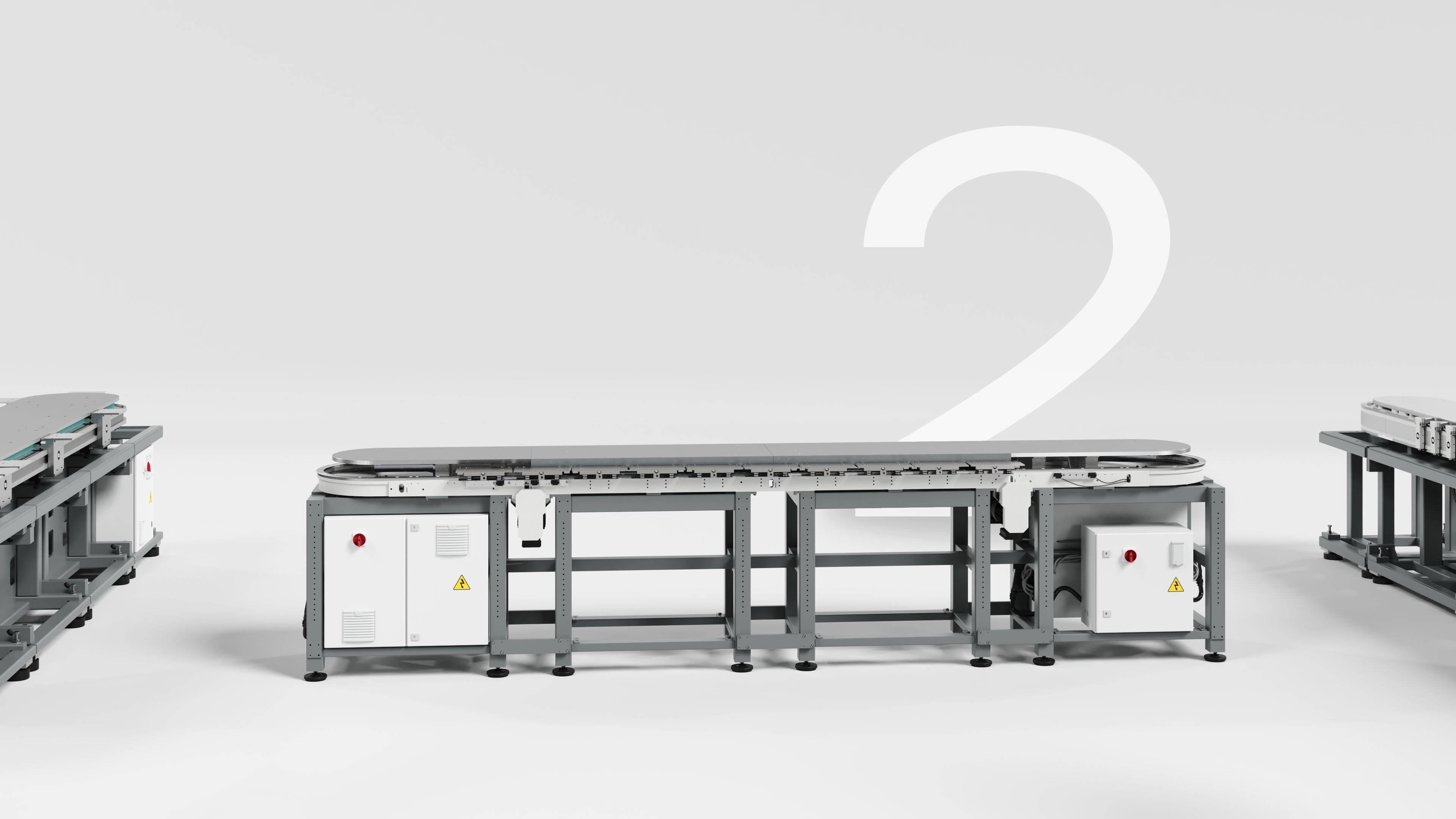

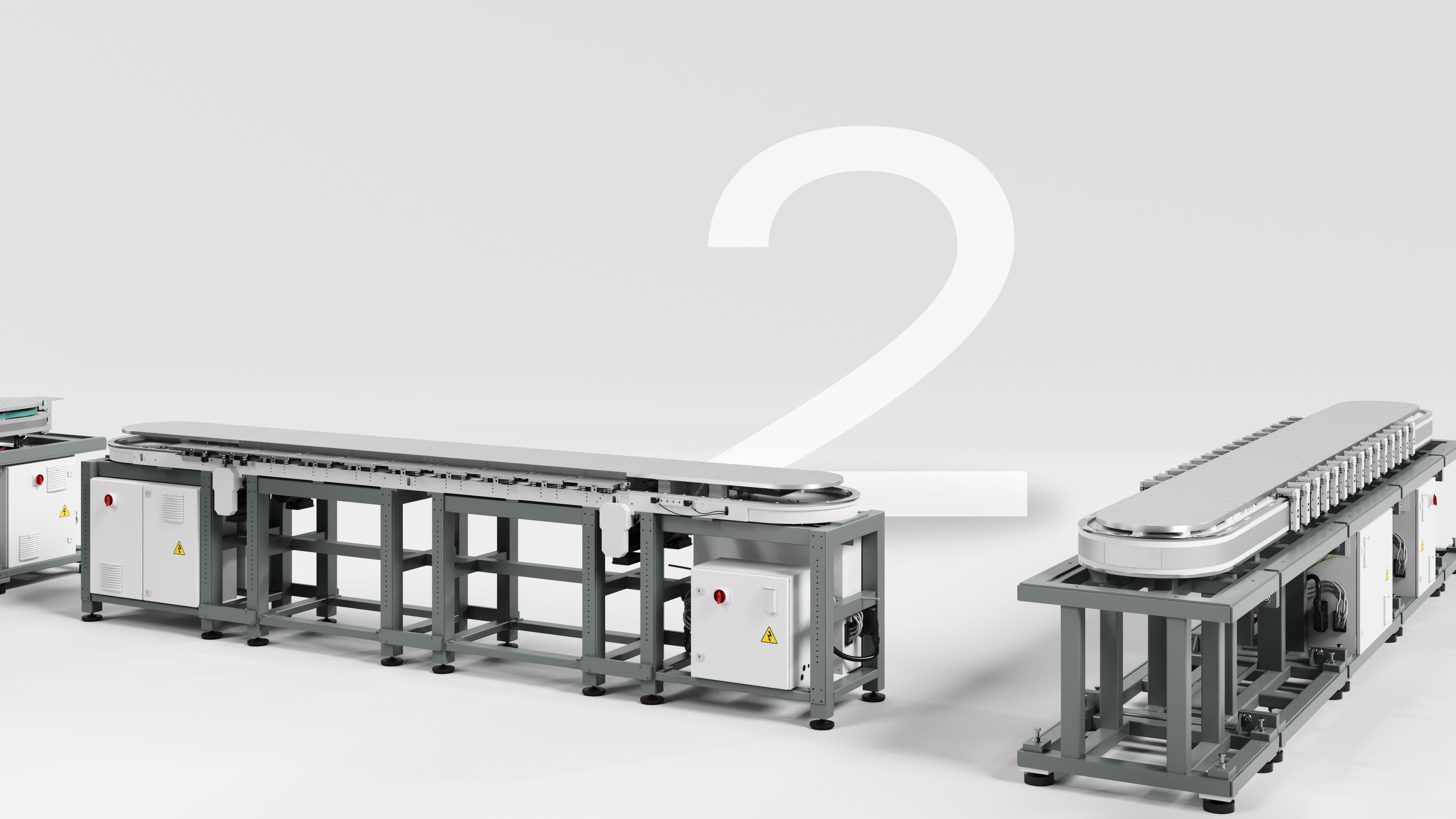

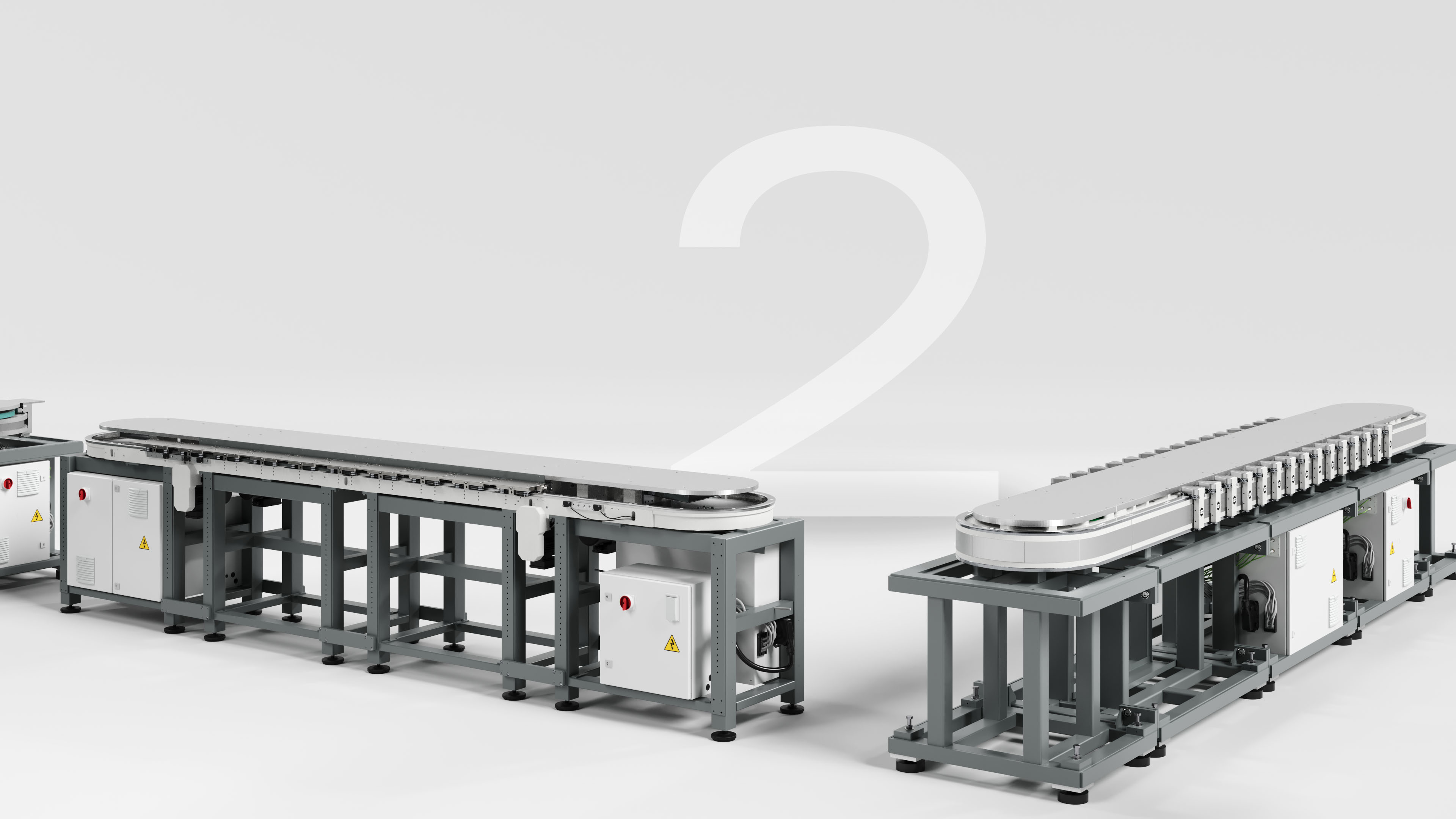

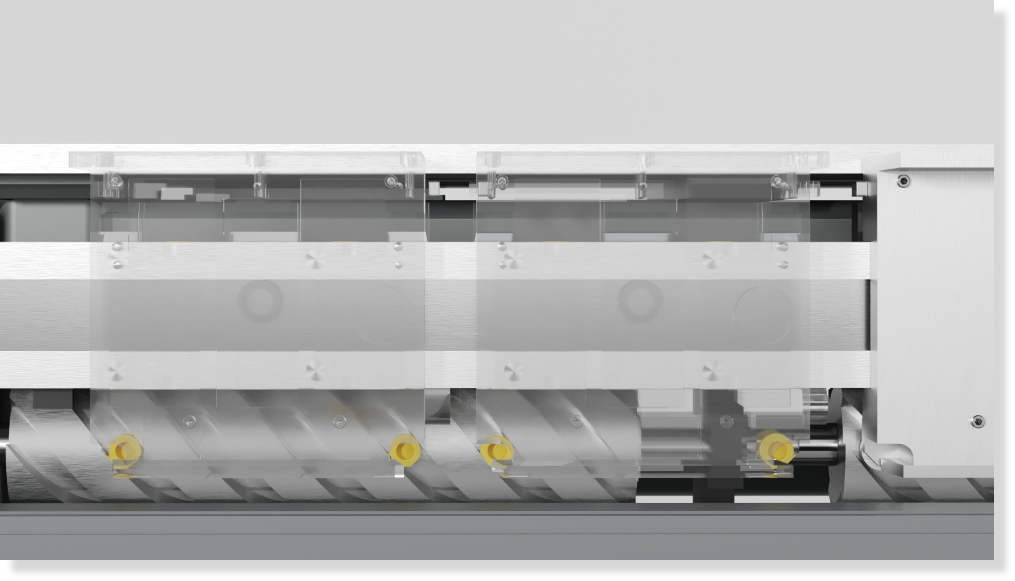

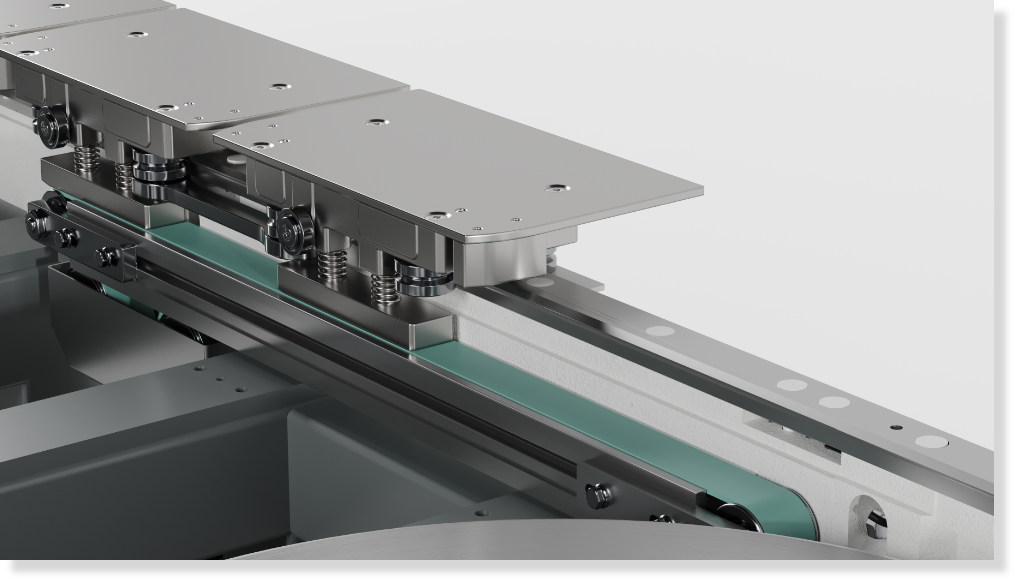

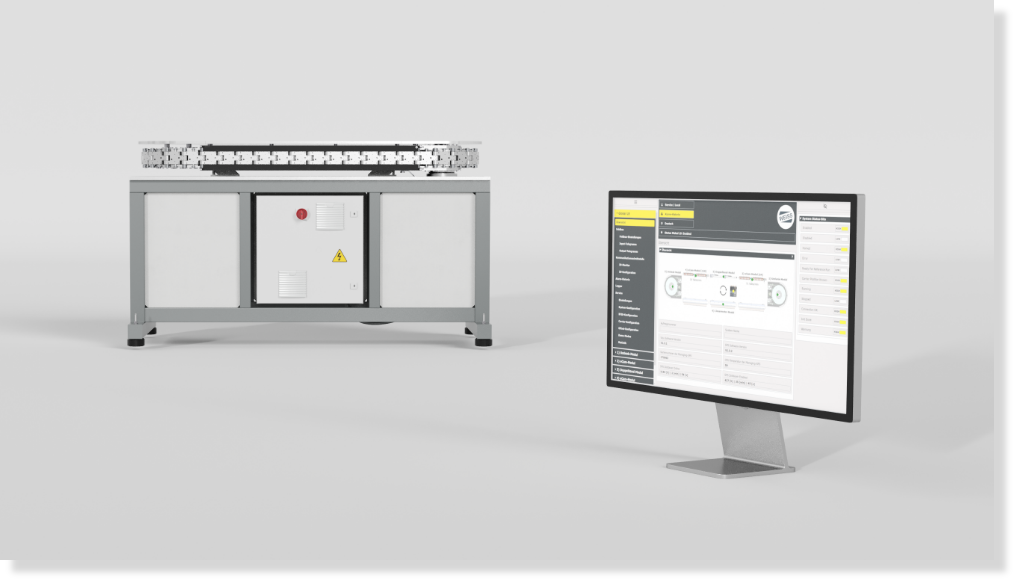

Linear transfer system

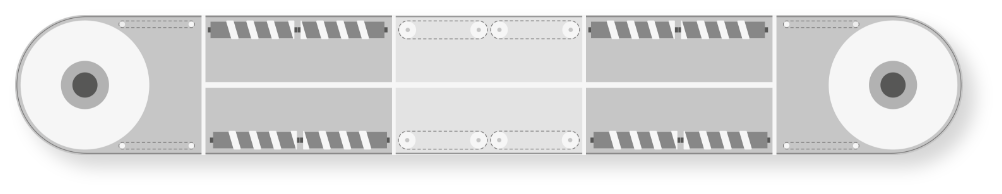

LS LINK

Efficient, easy and fast. The LS Link timing based on link

conveyor technology the newest member of the

WEISS Linear Transfer Systems.

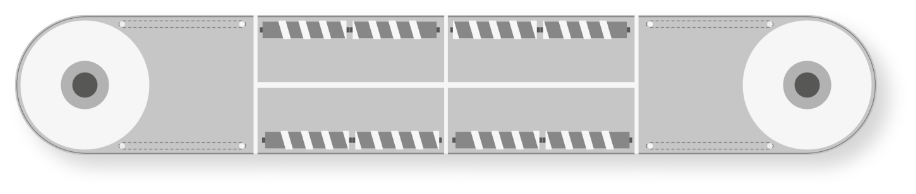

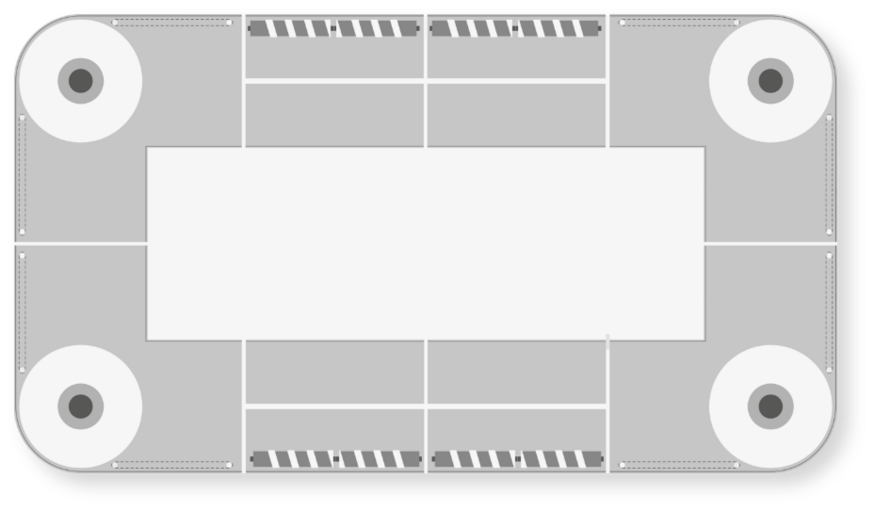

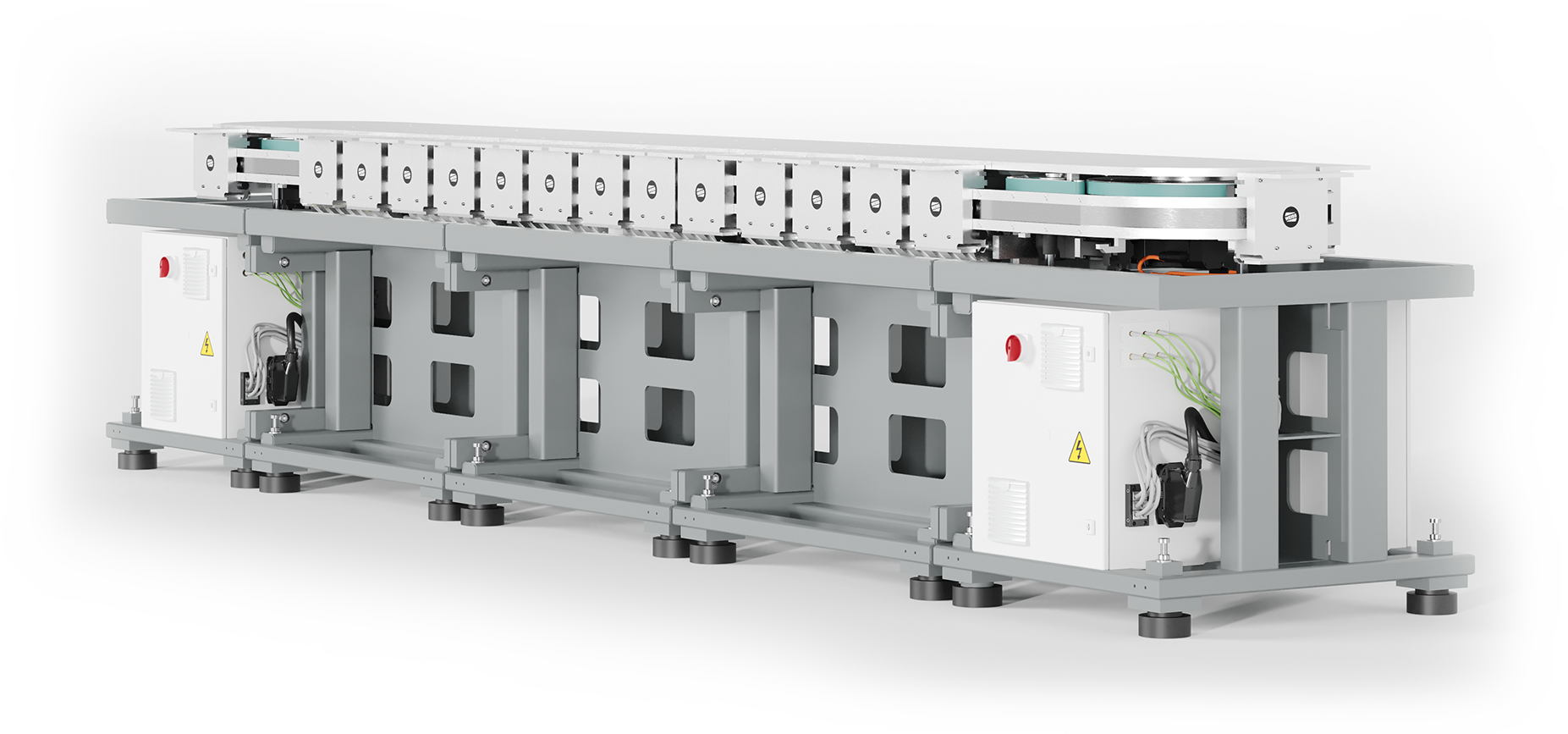

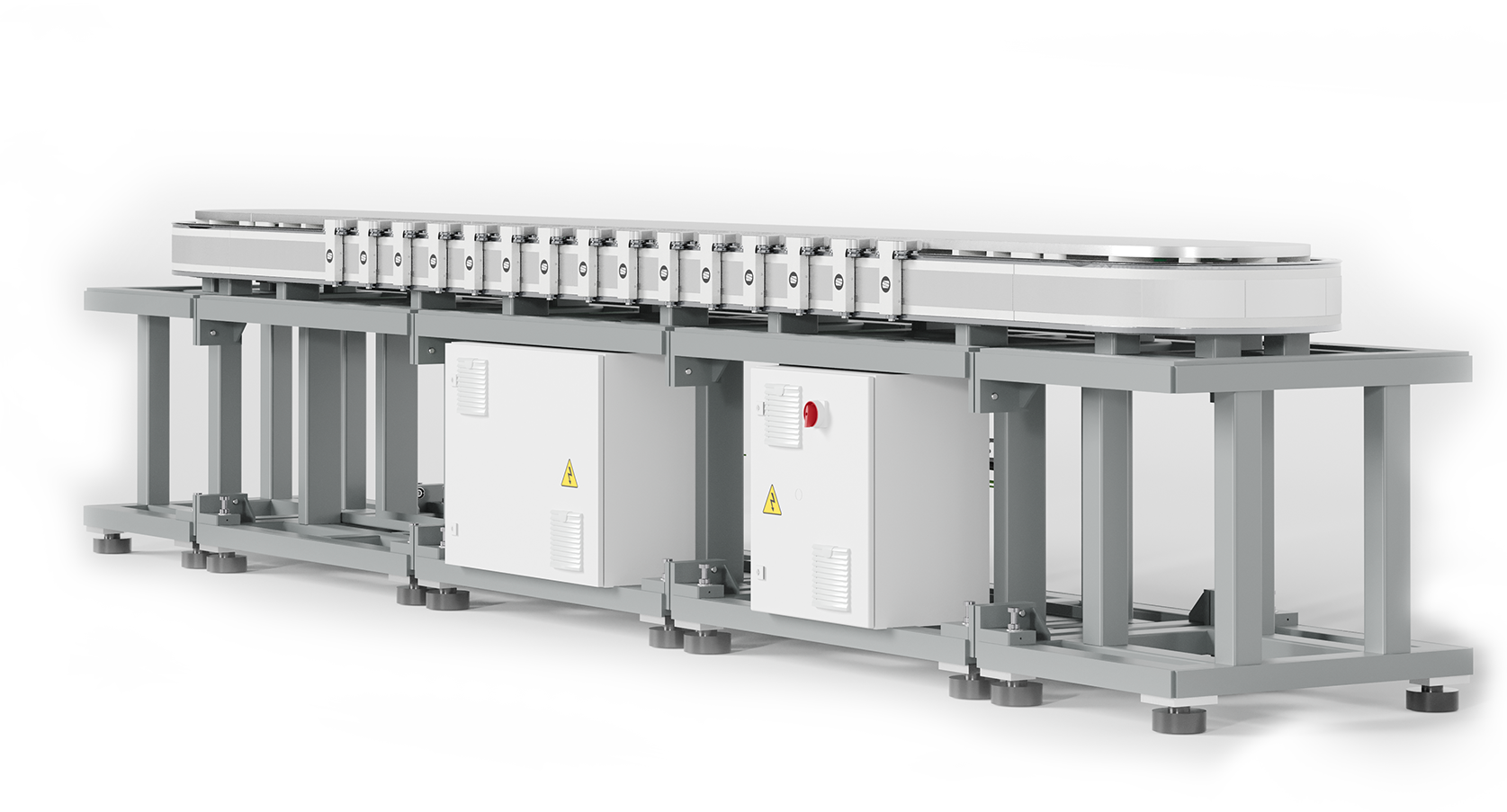

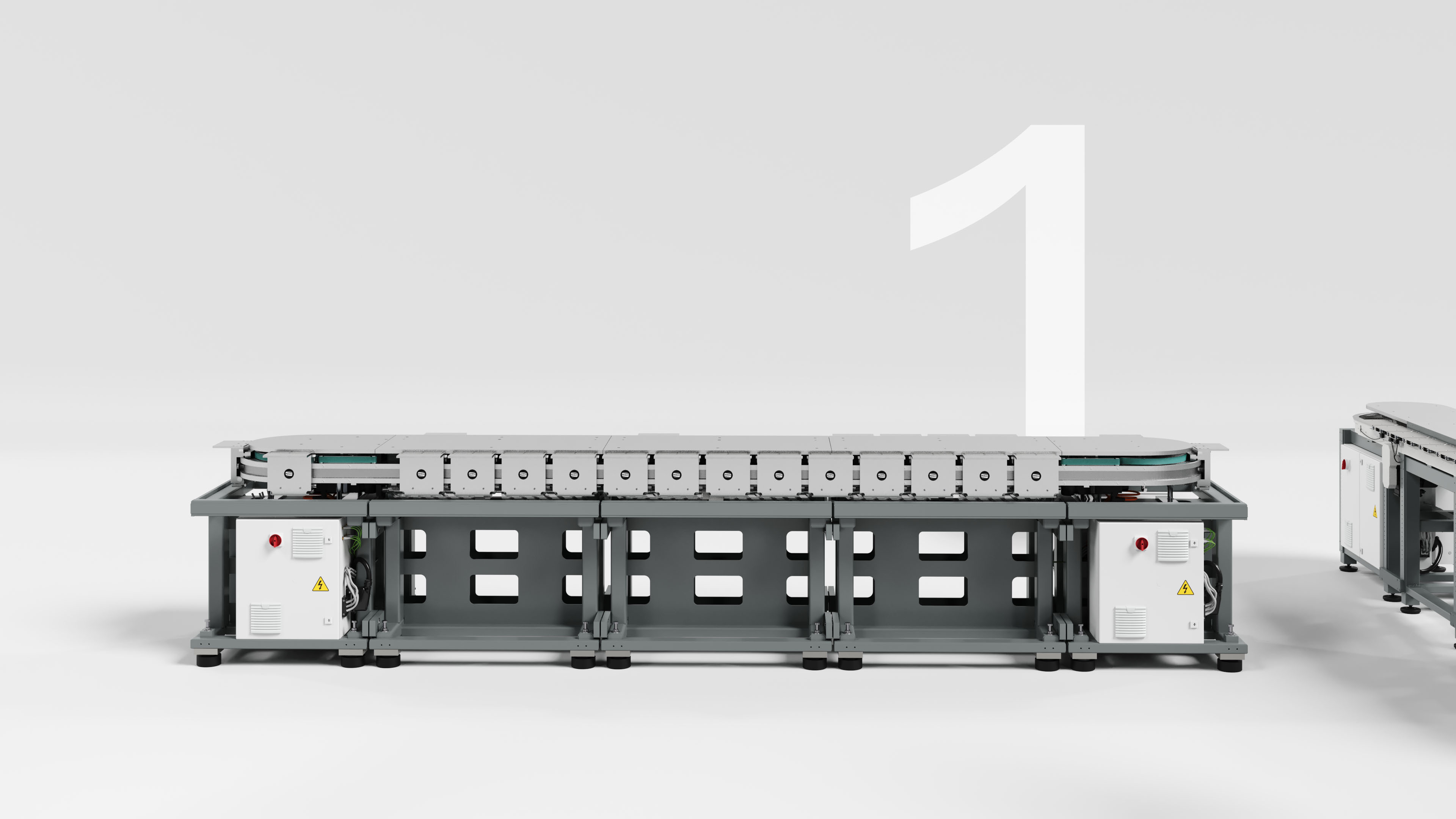

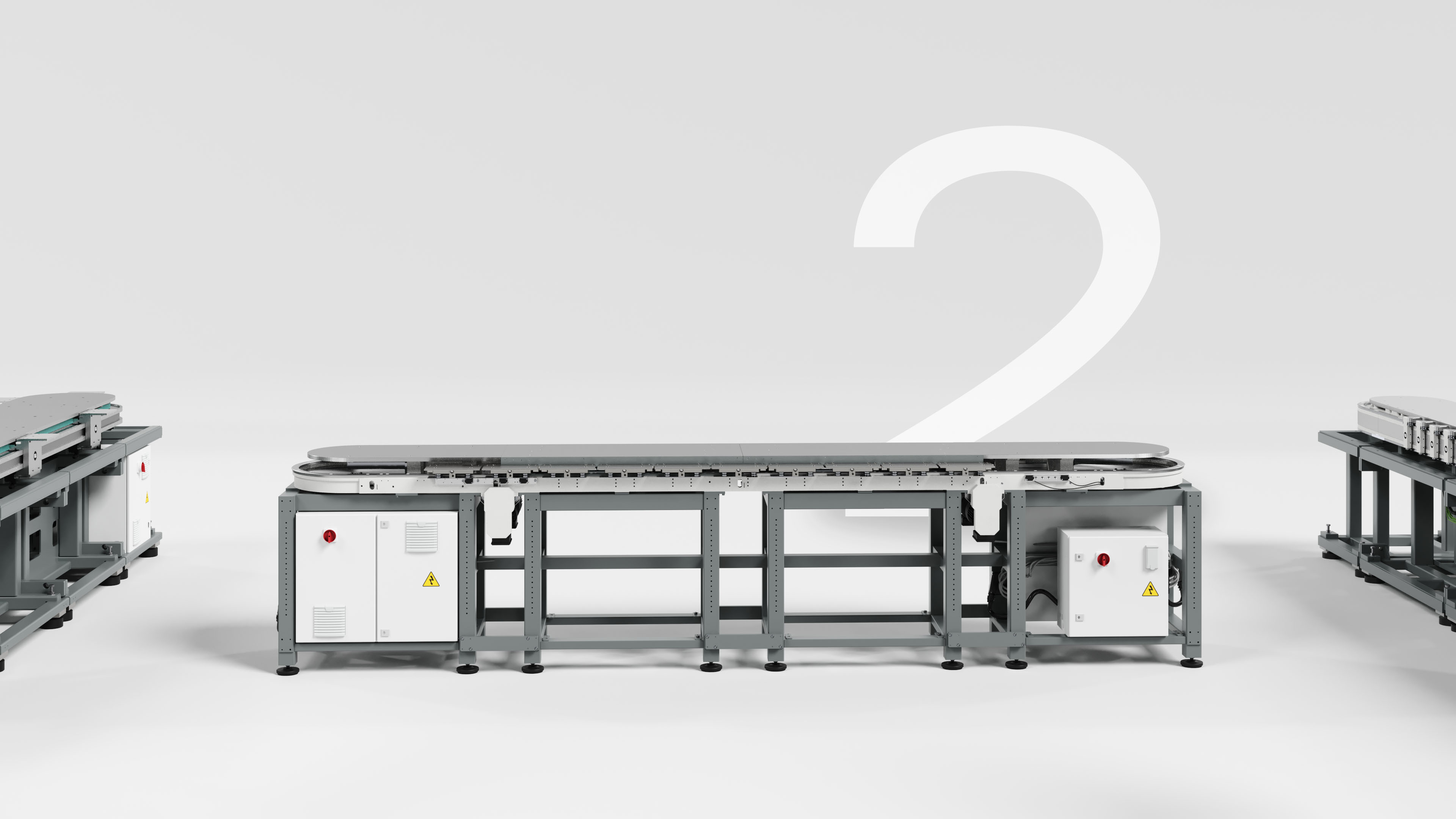

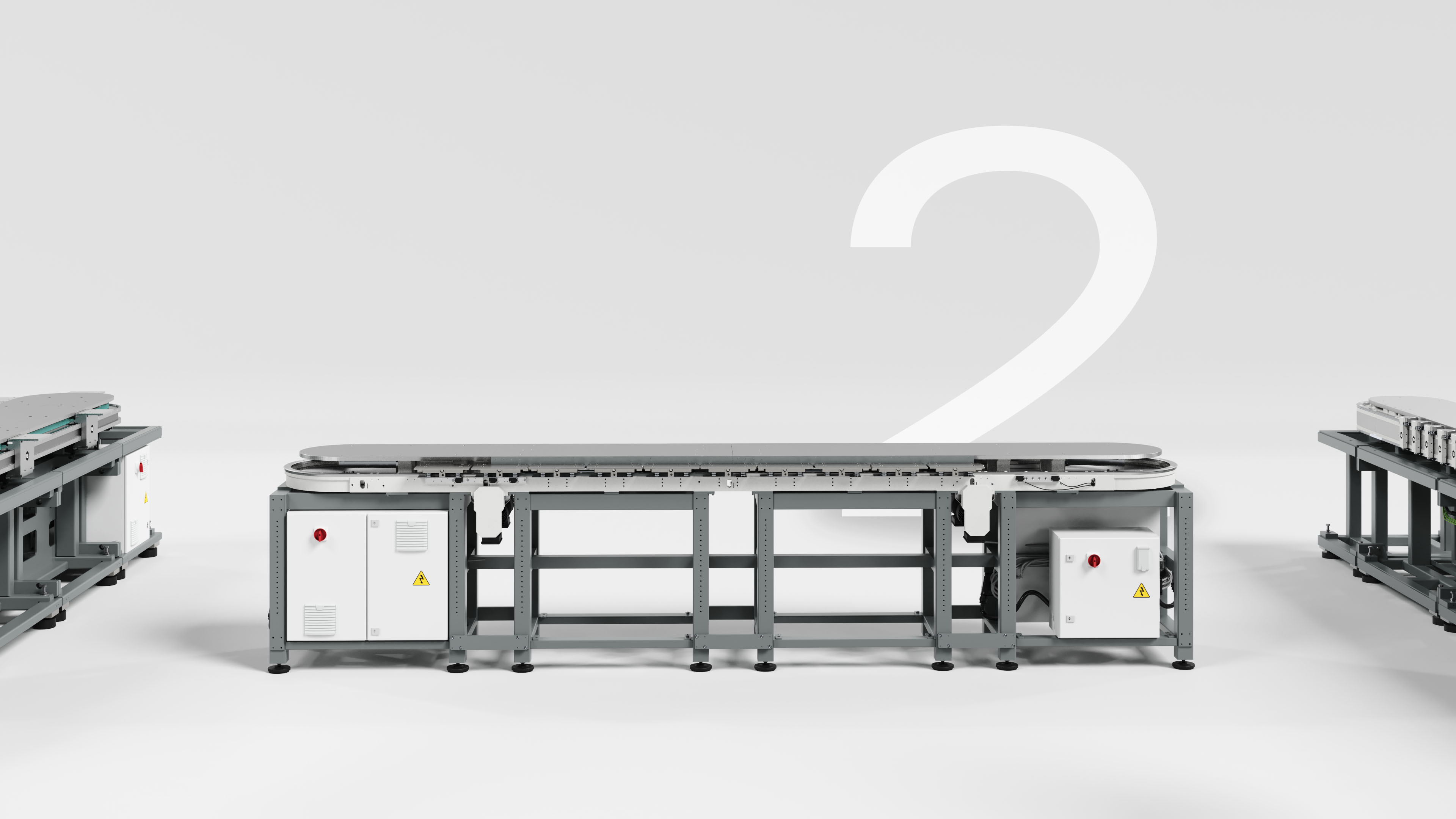

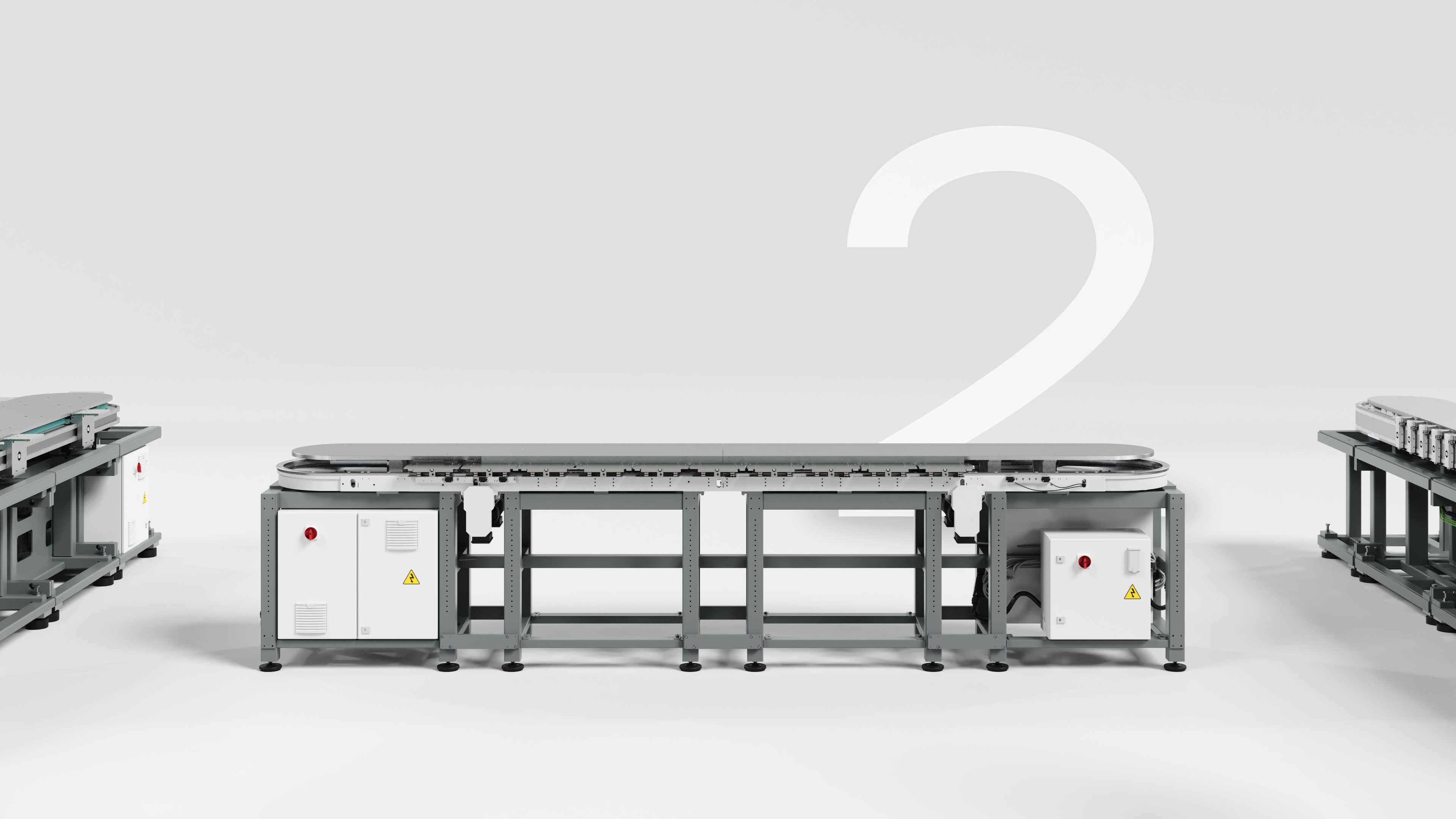

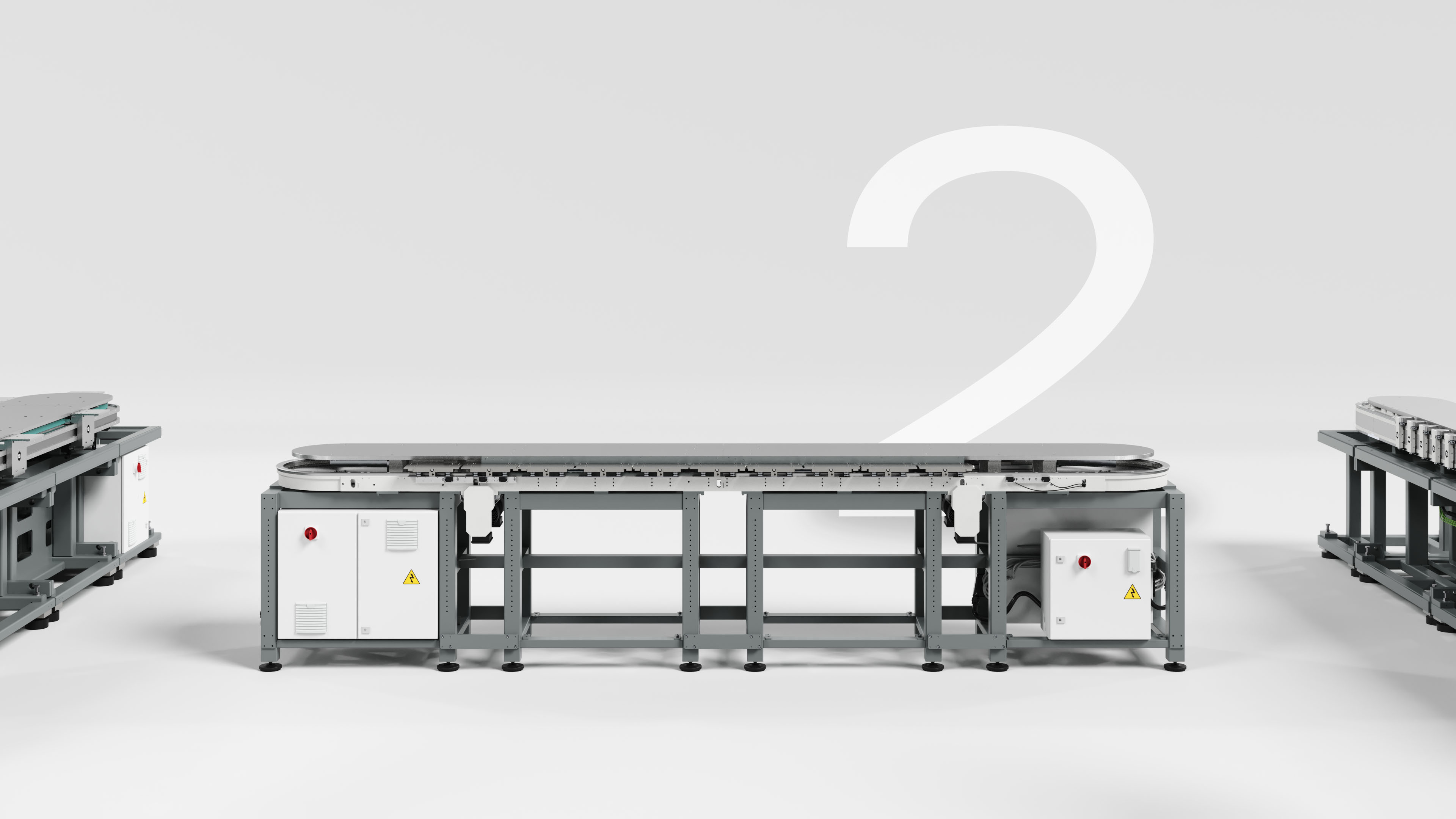

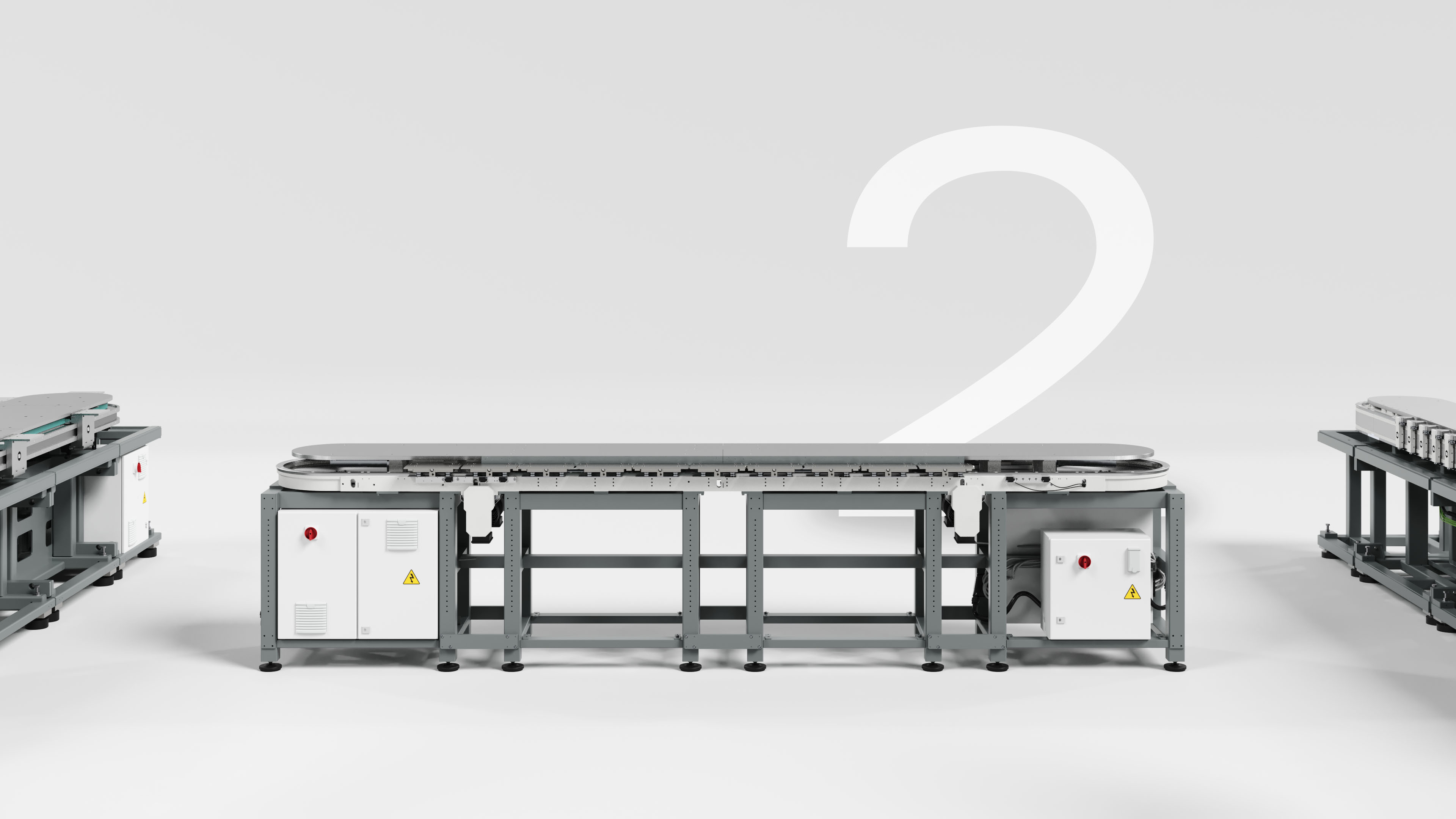

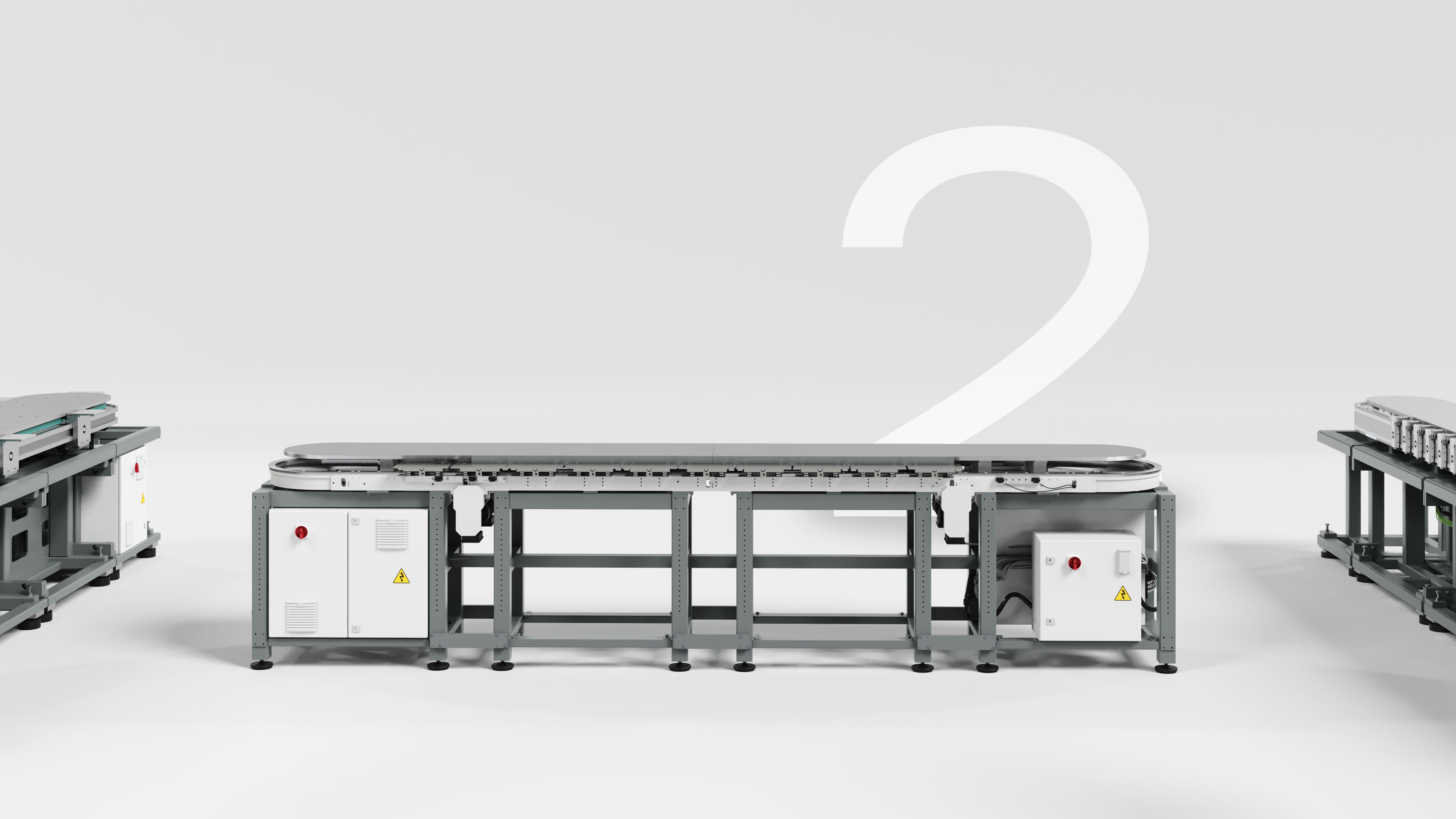

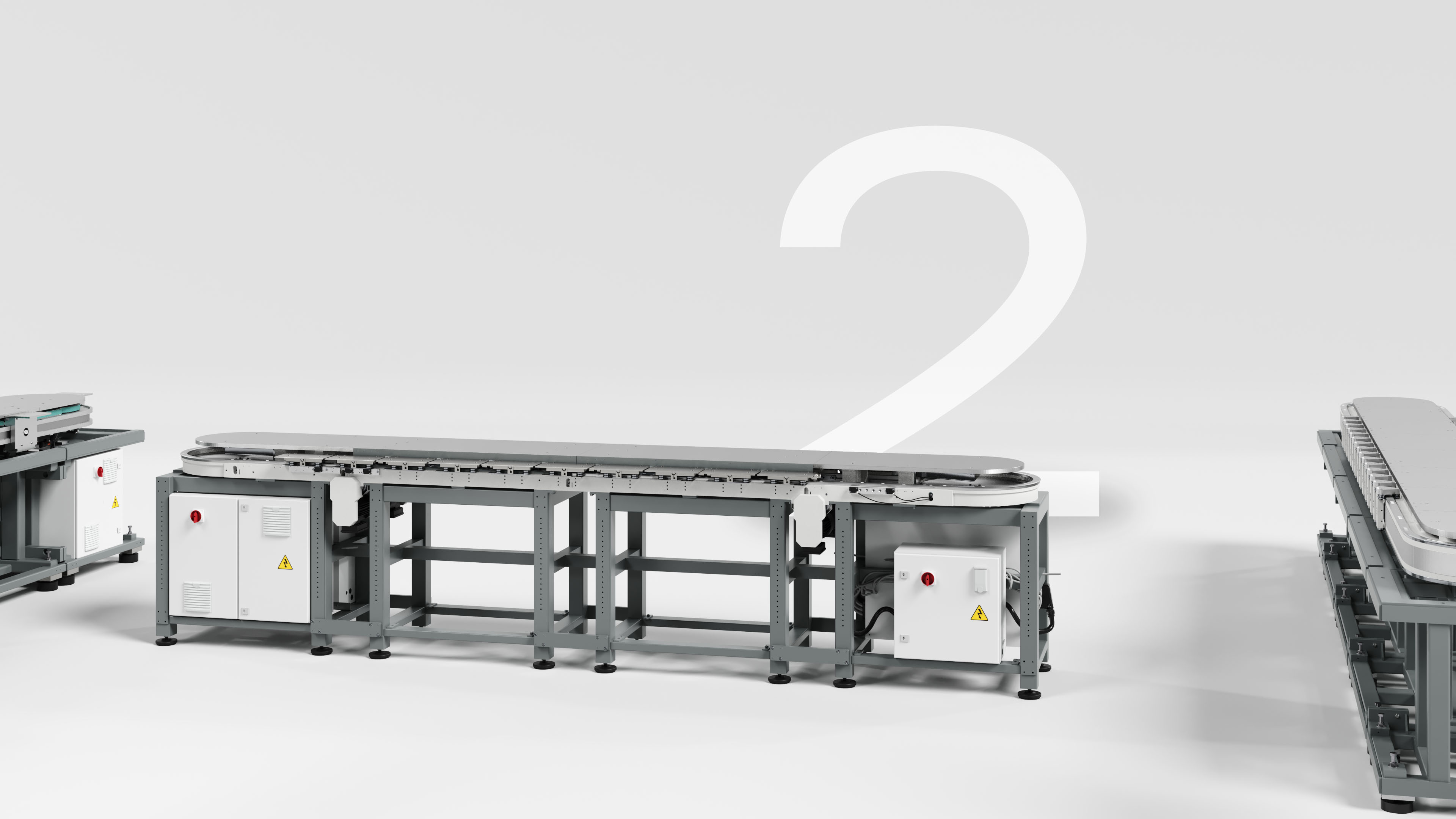

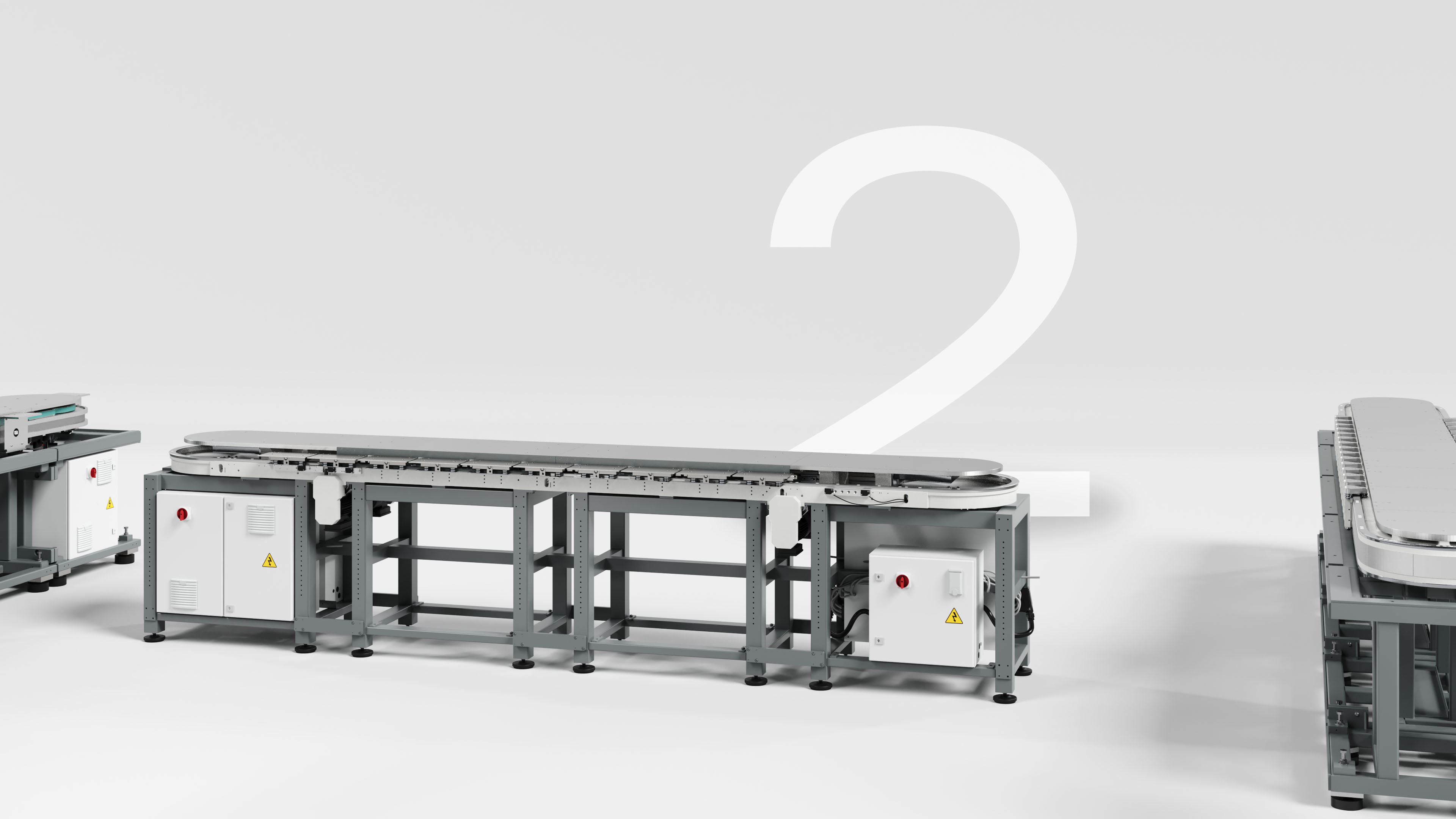

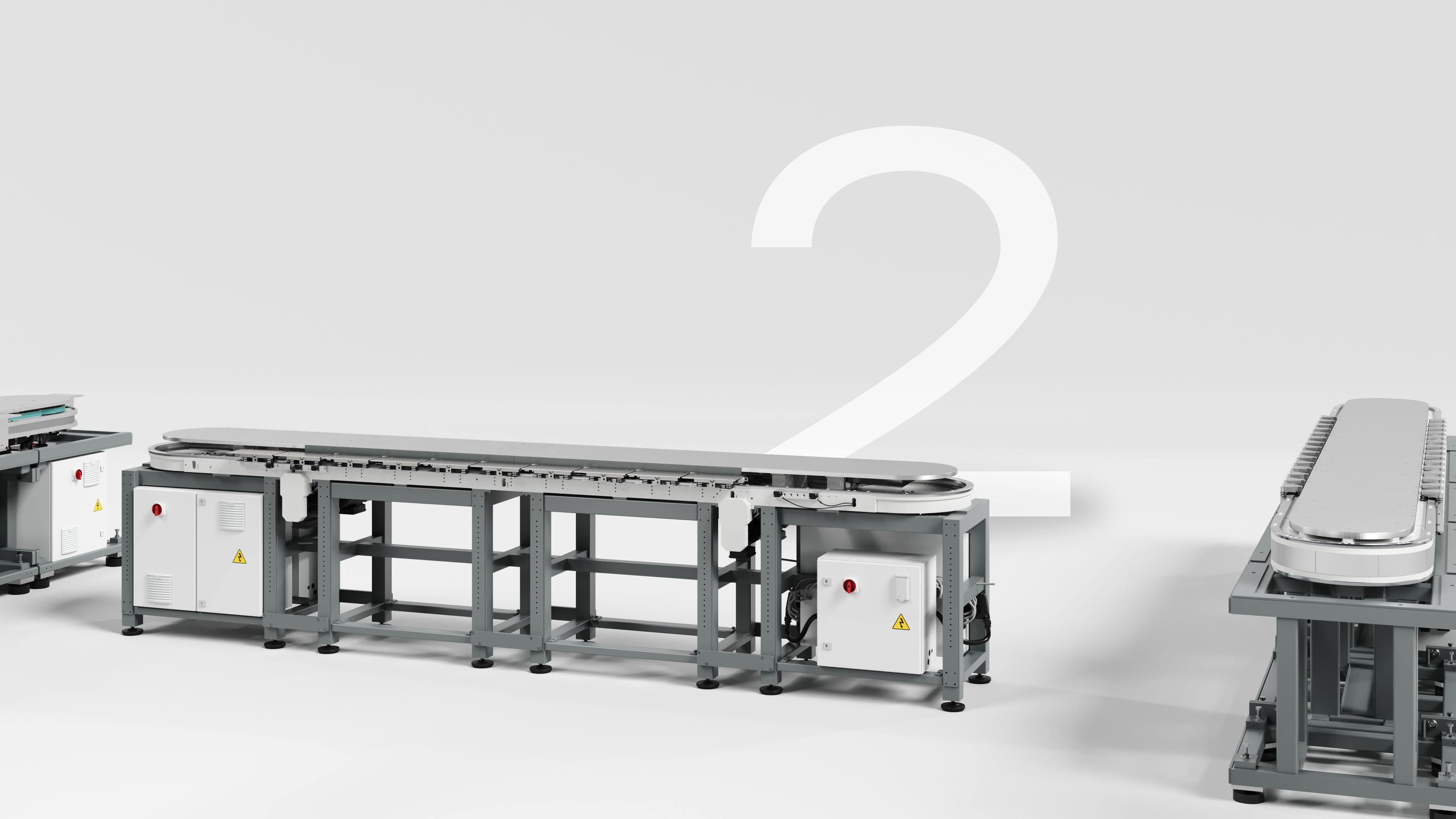

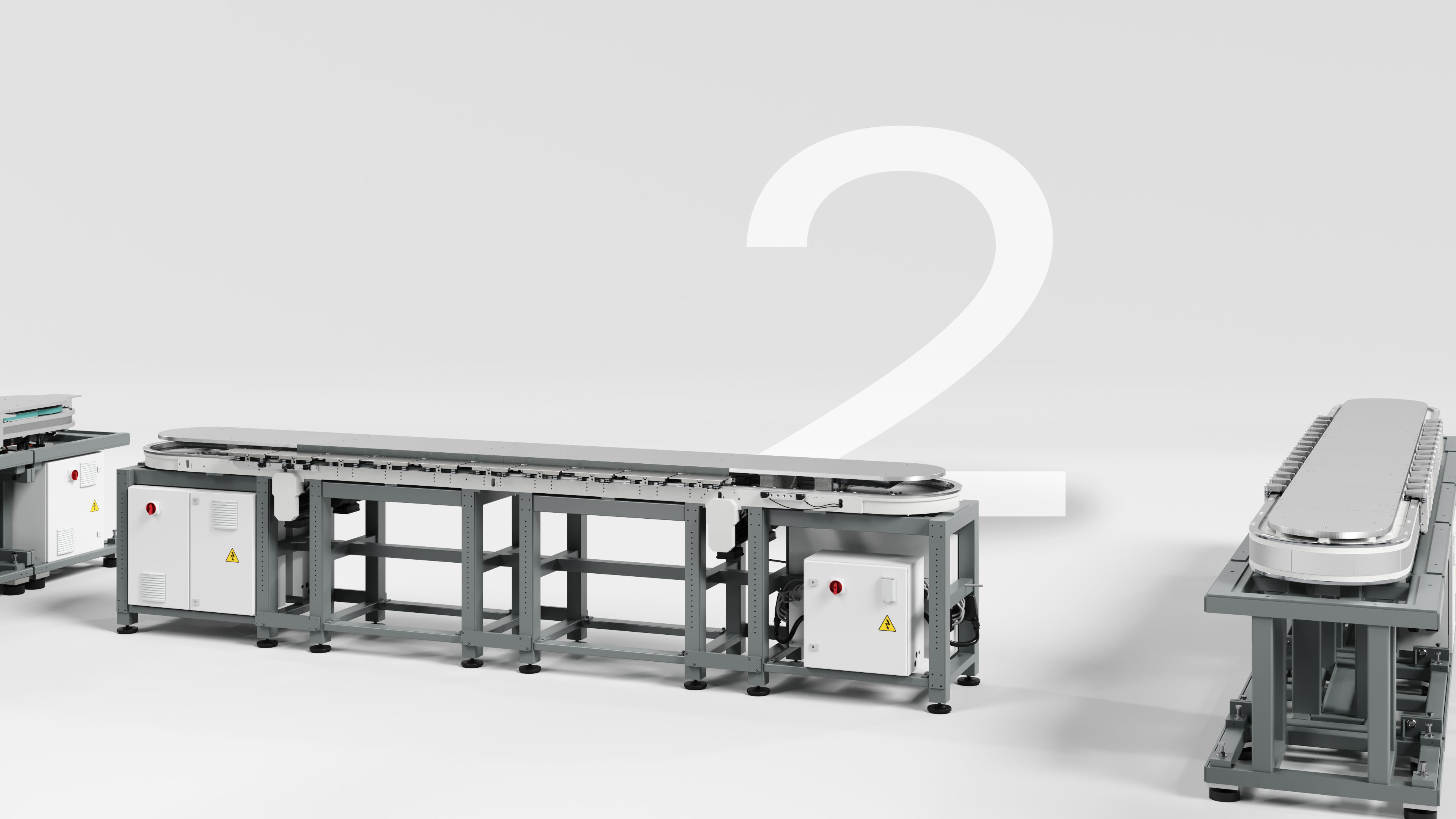

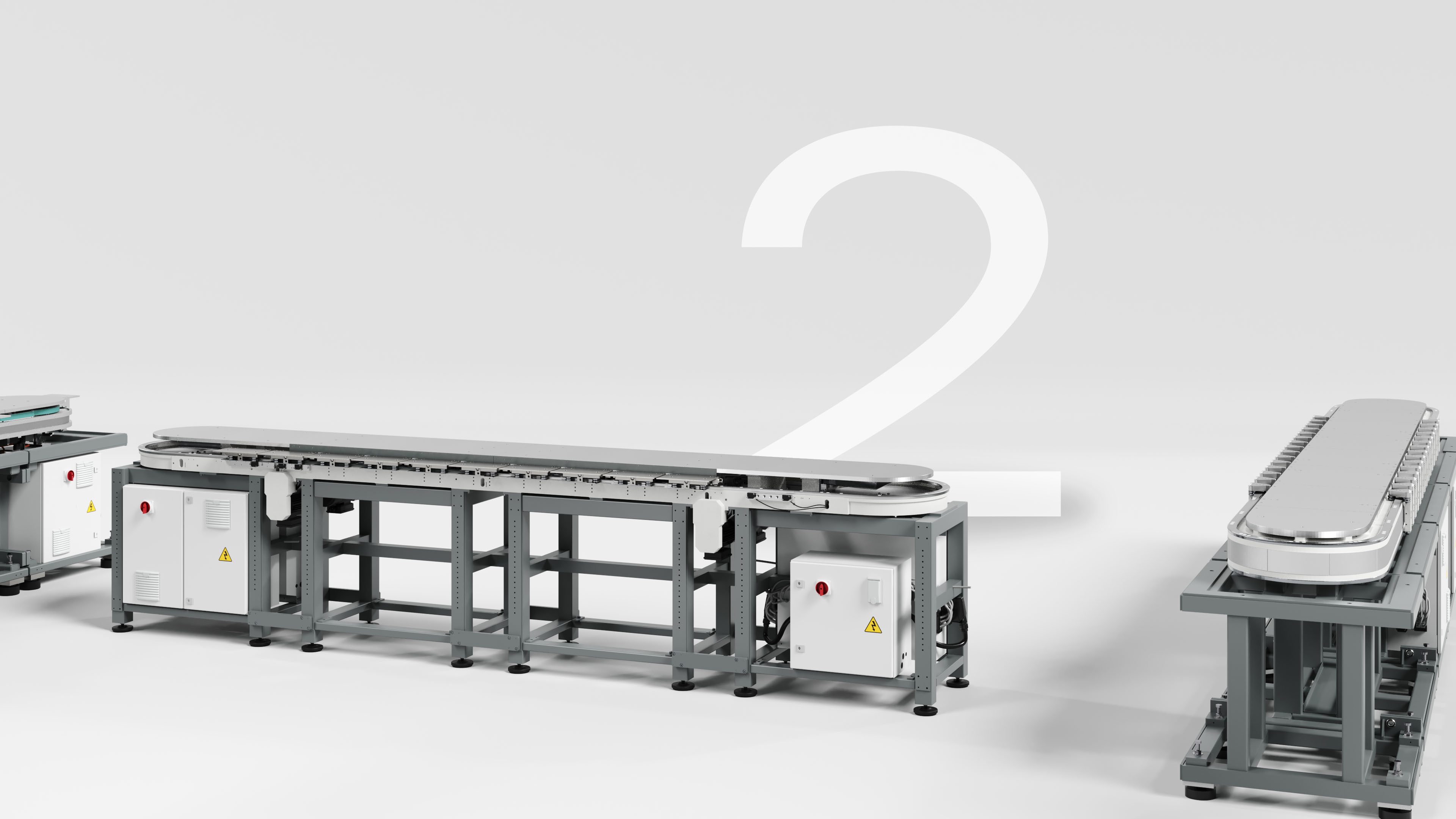

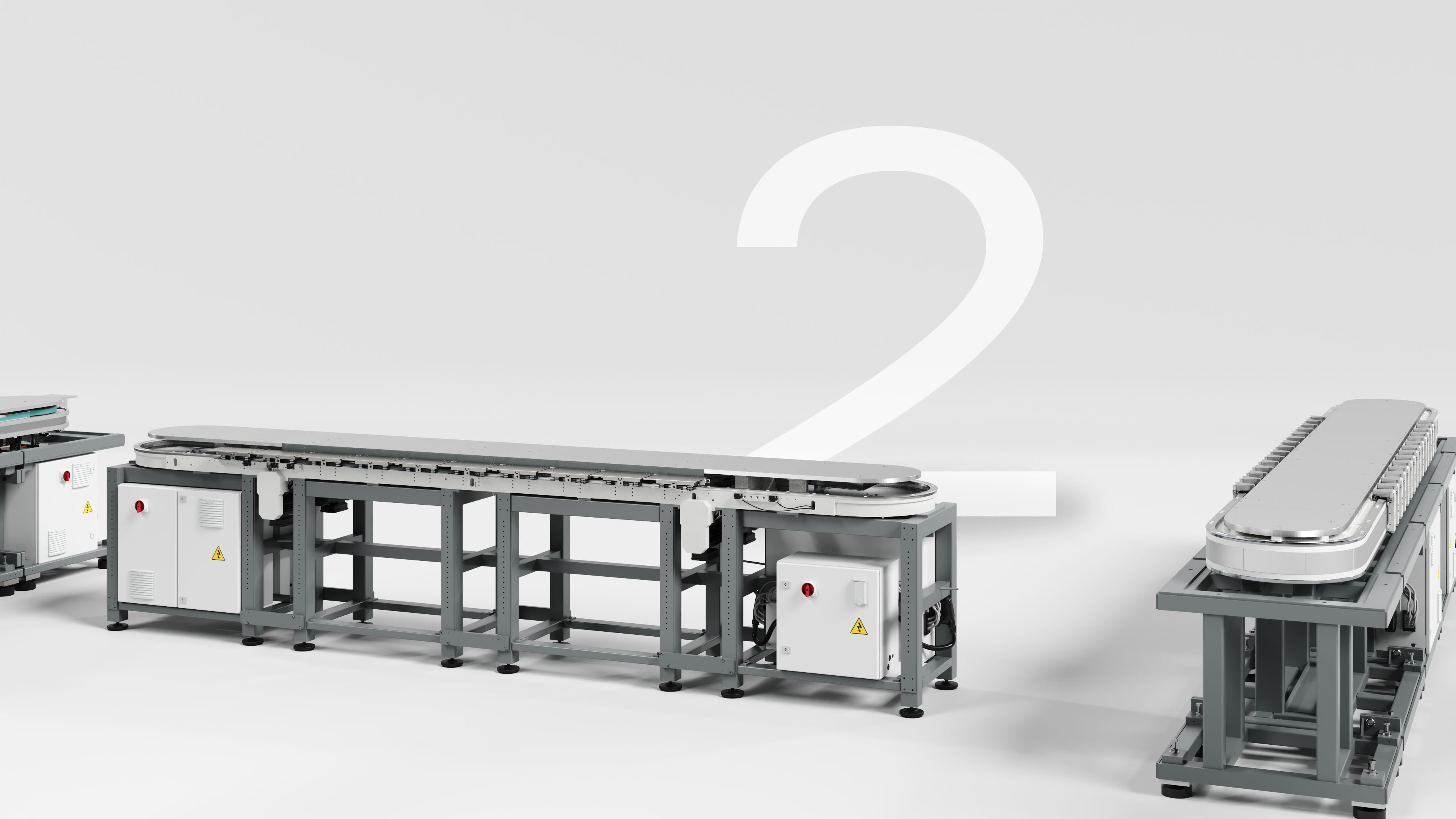

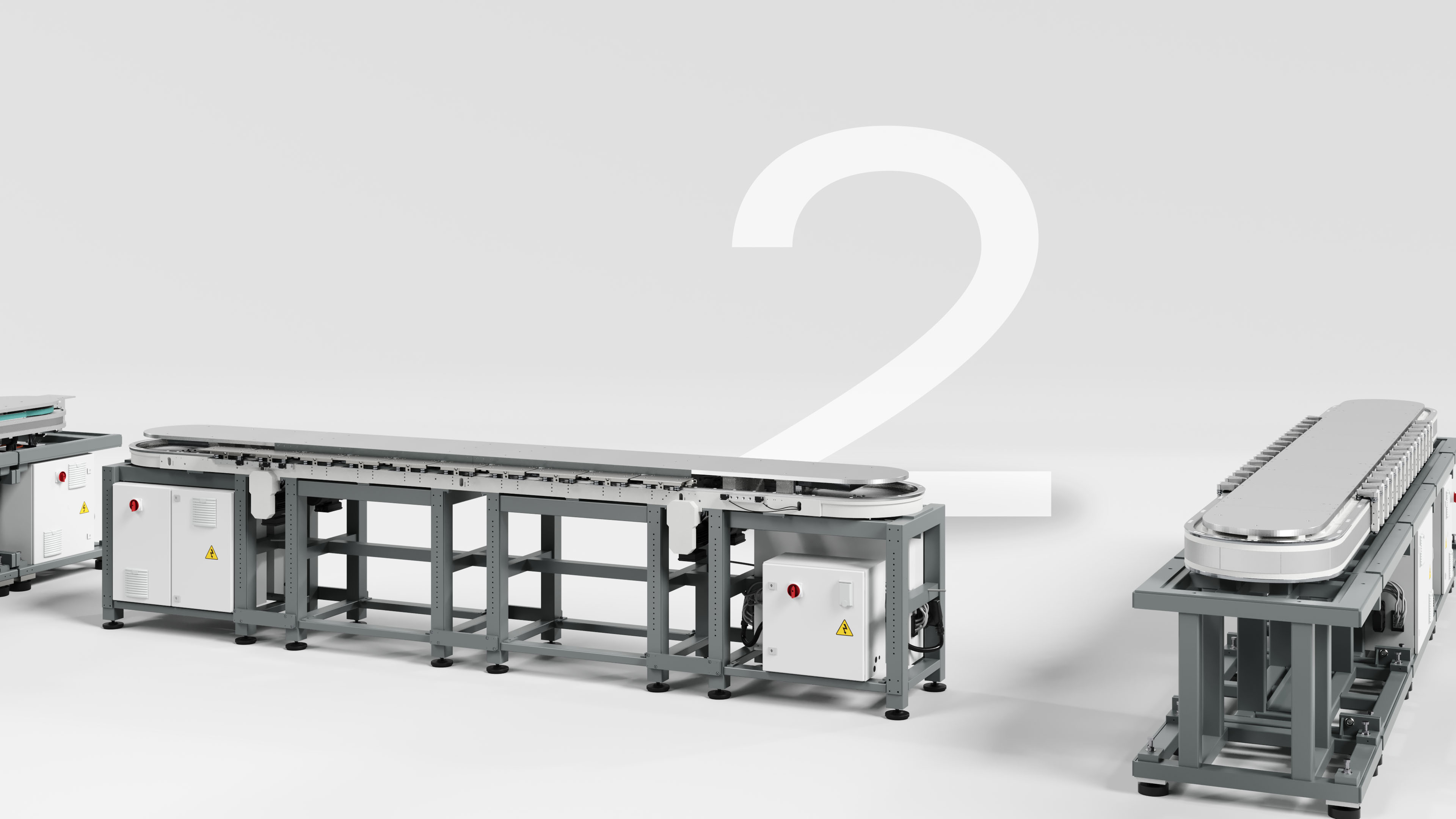

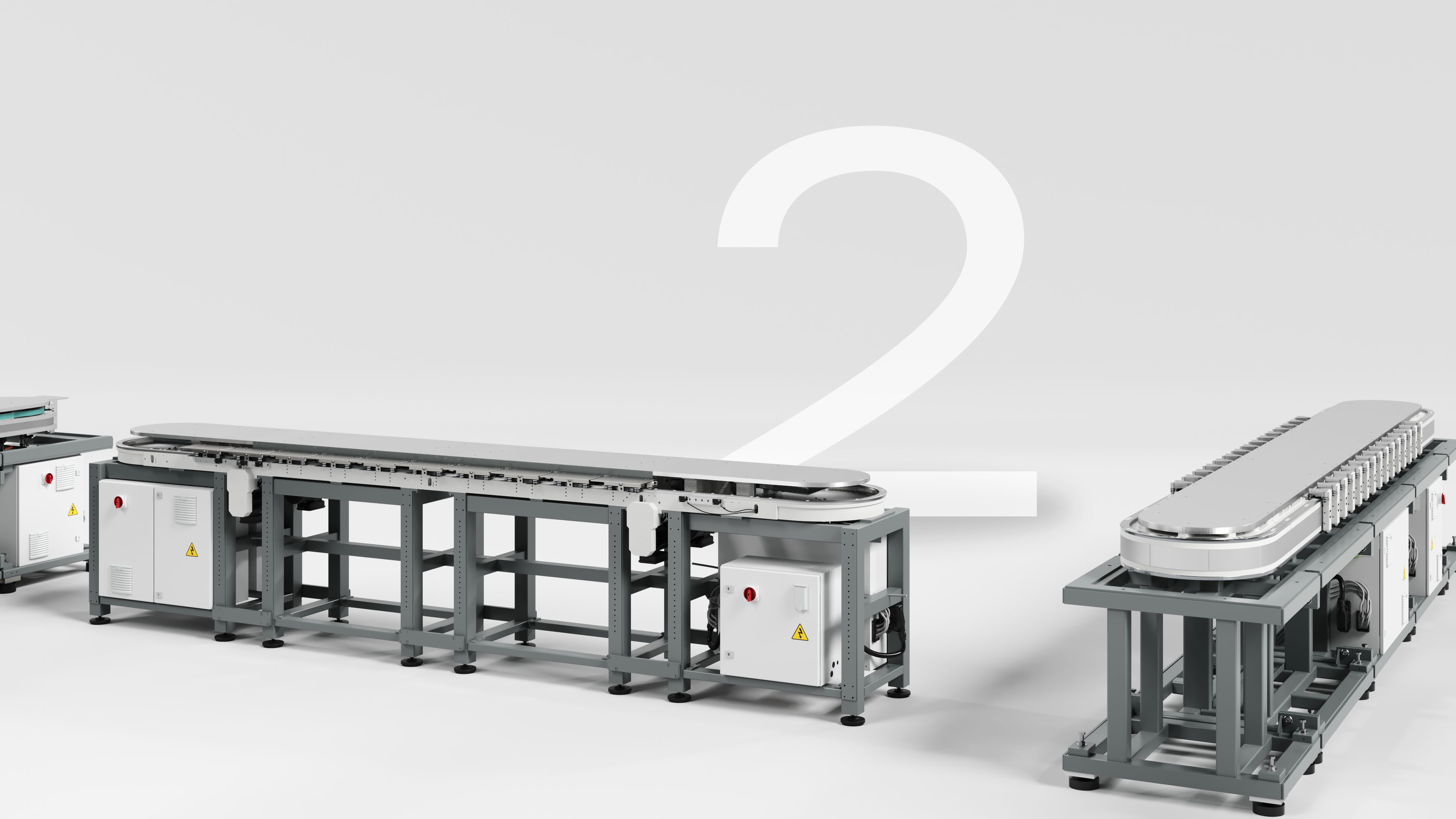

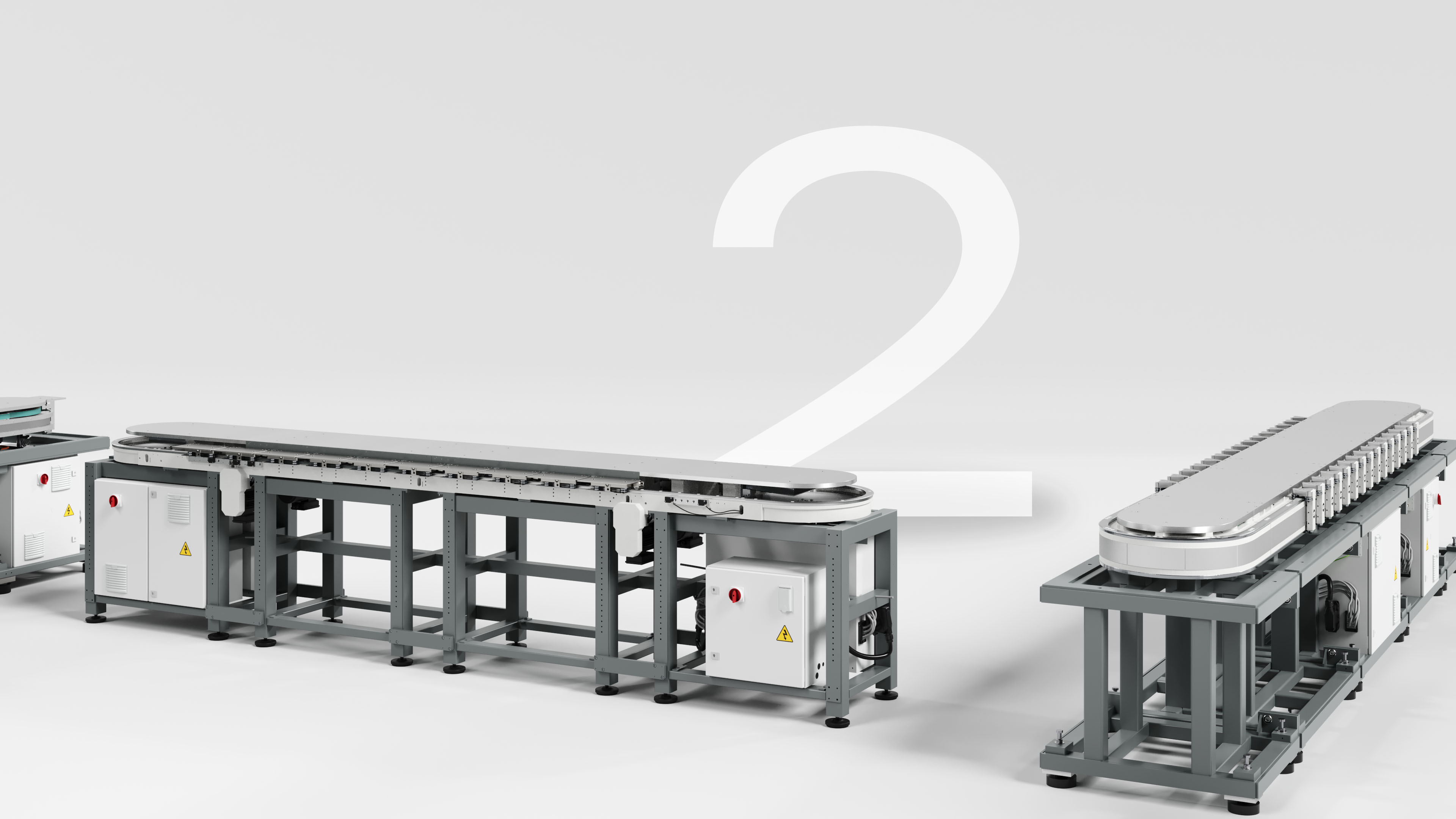

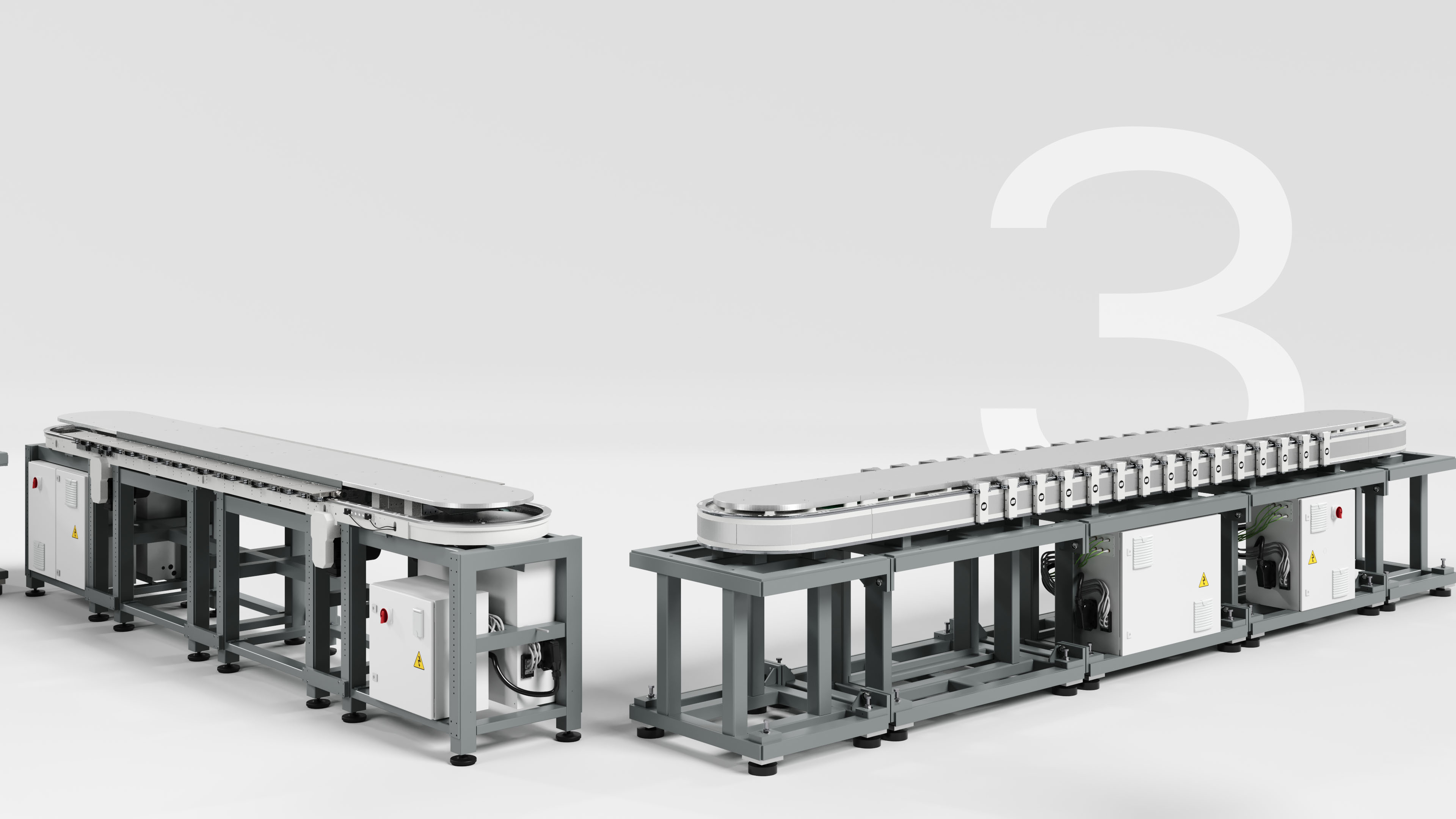

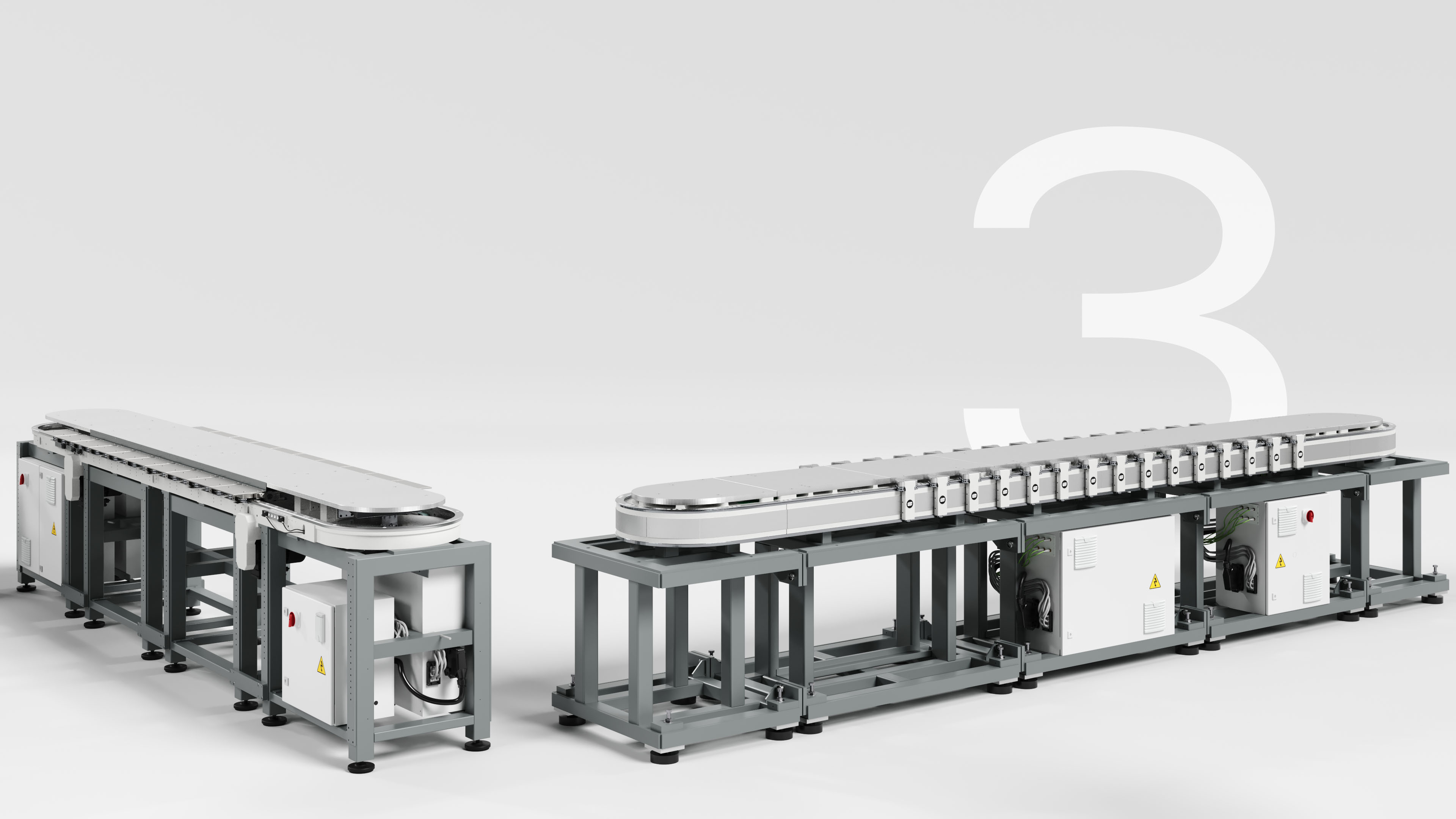

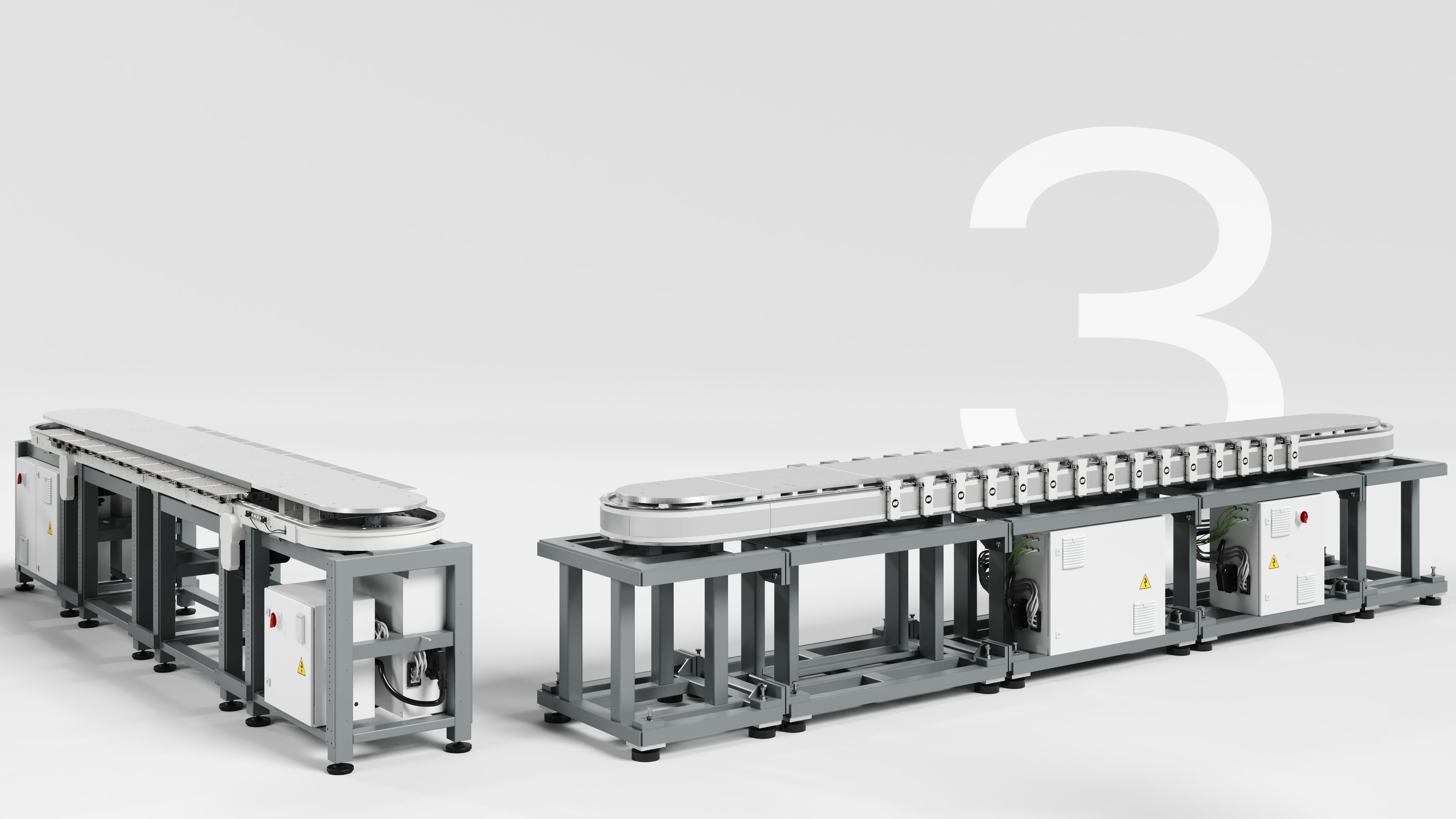

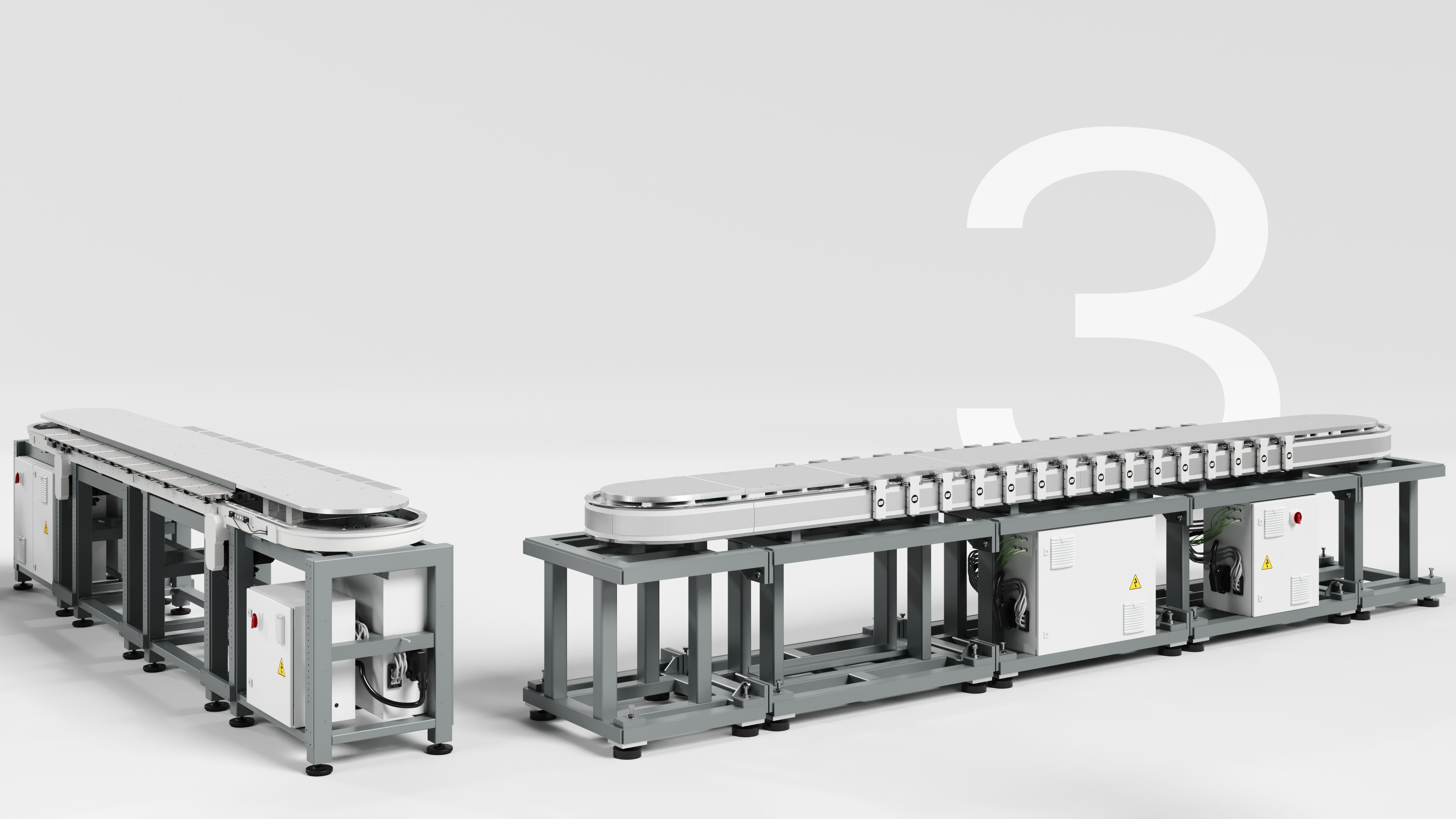

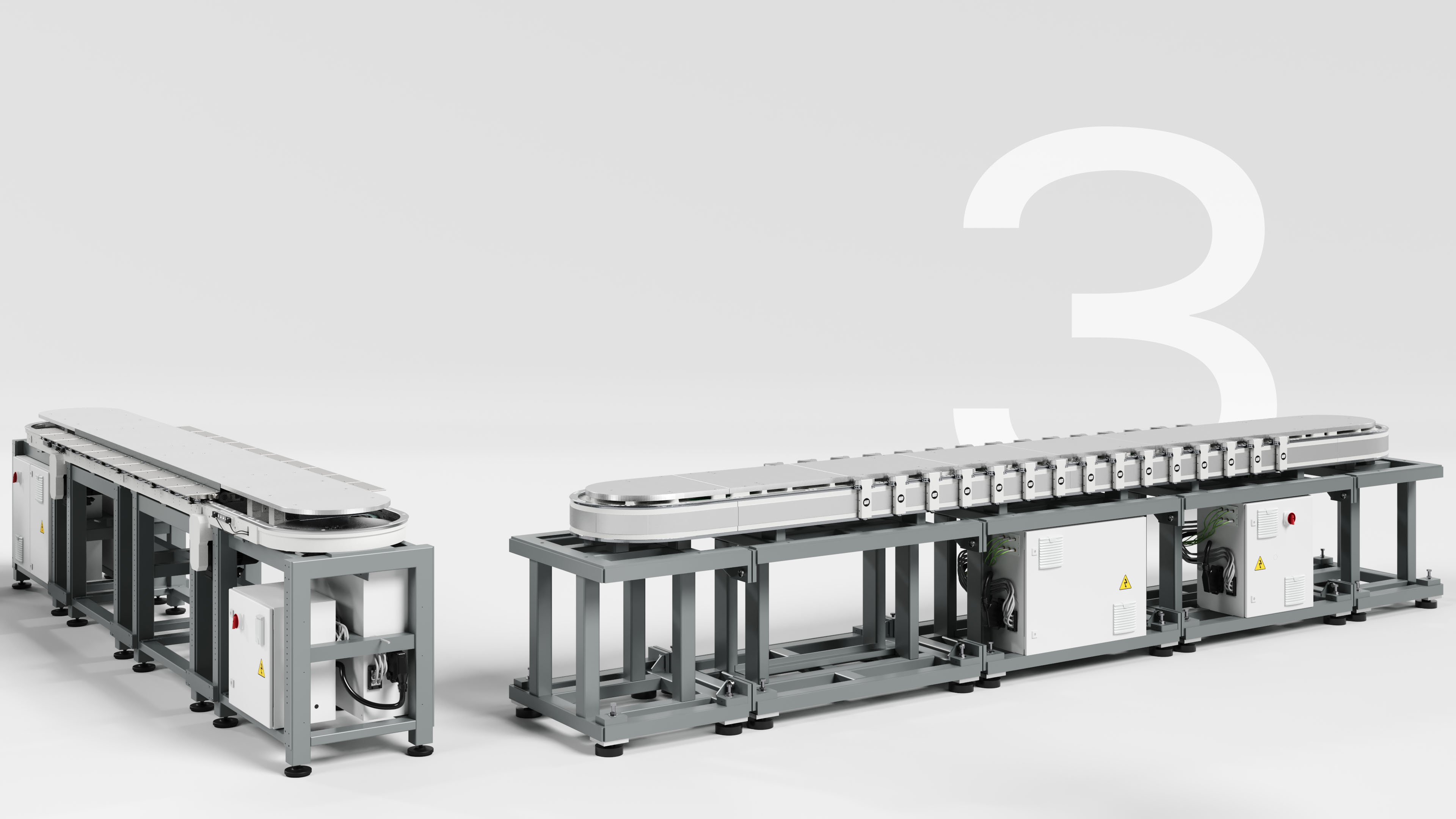

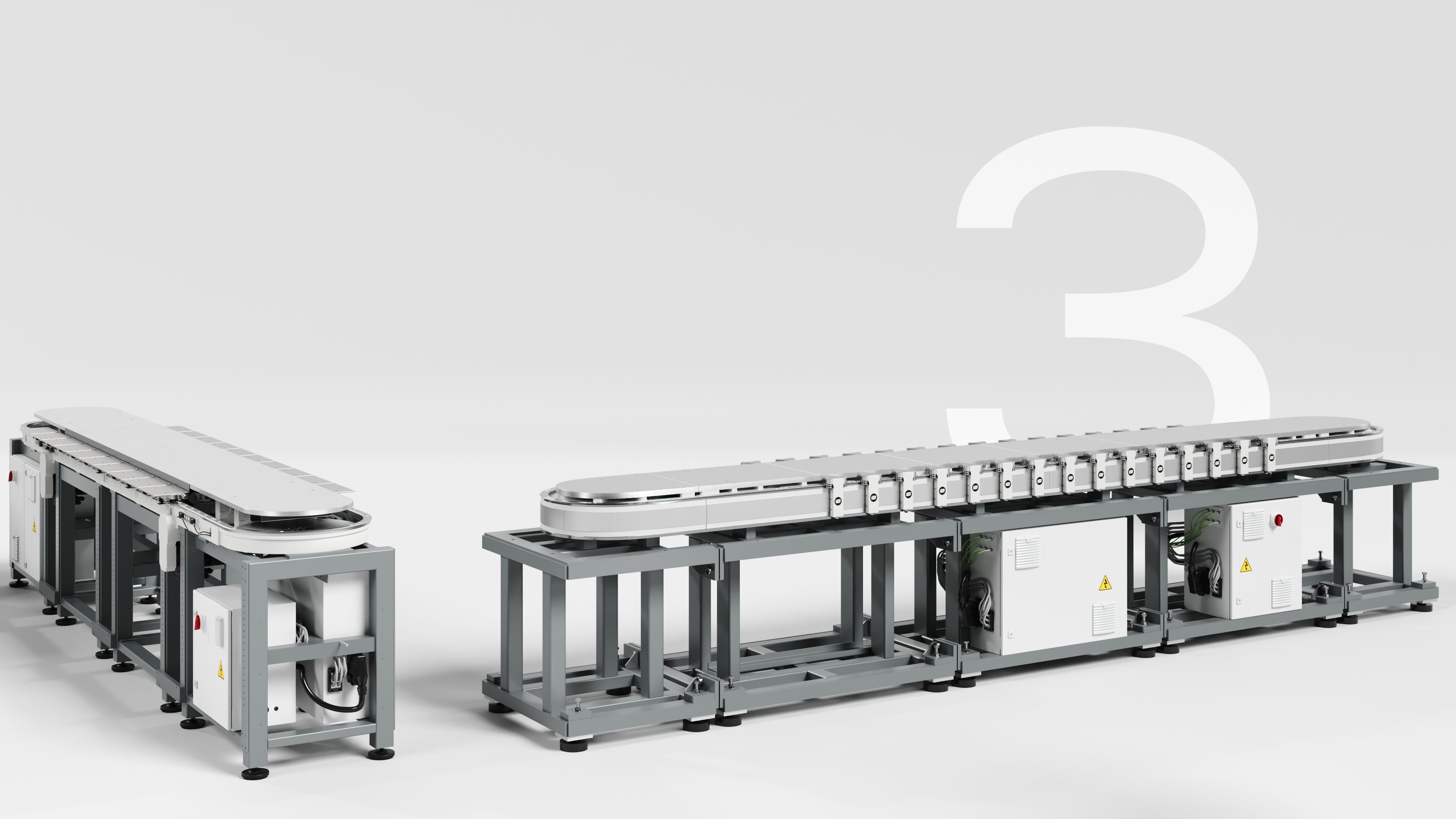

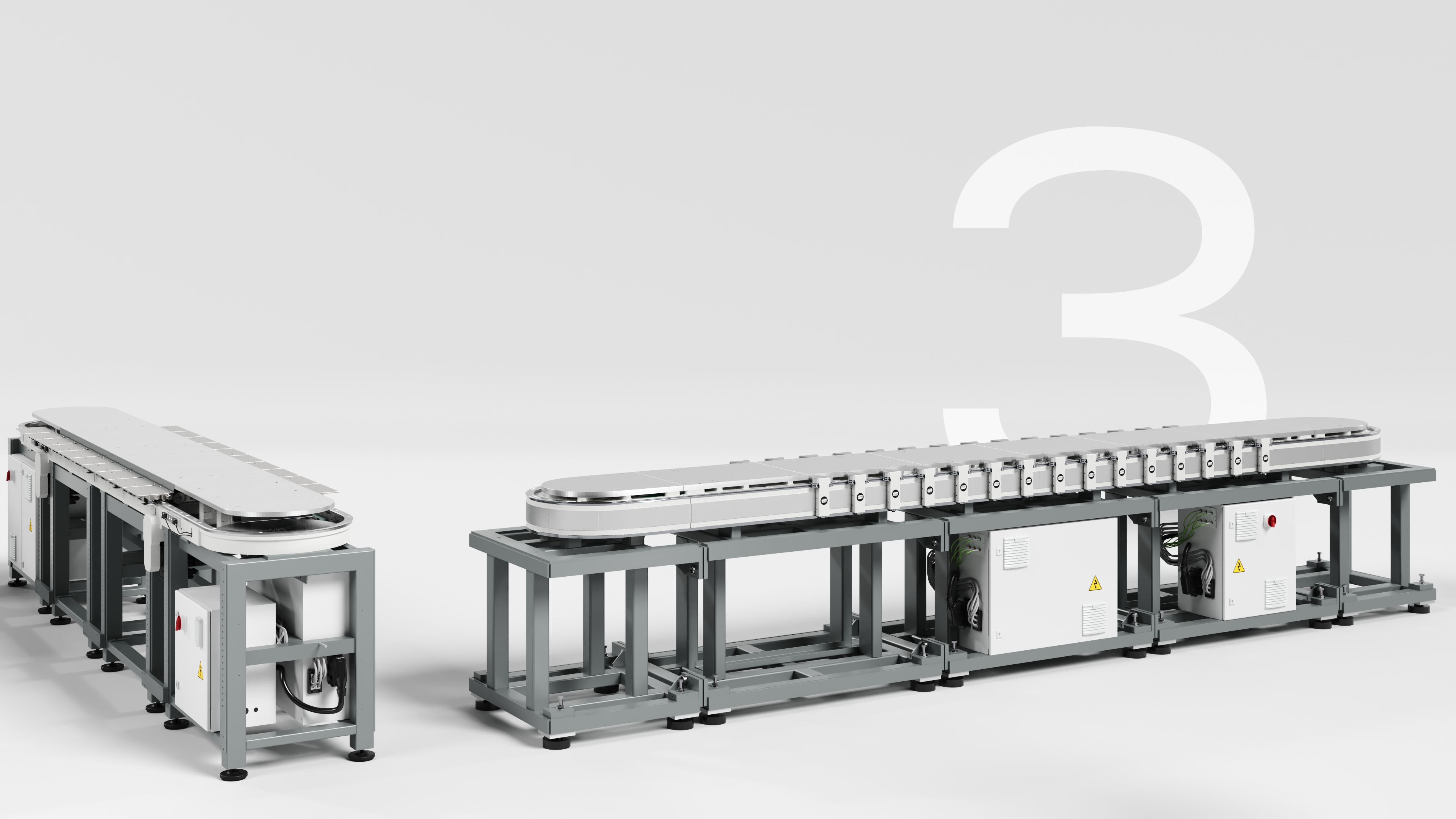

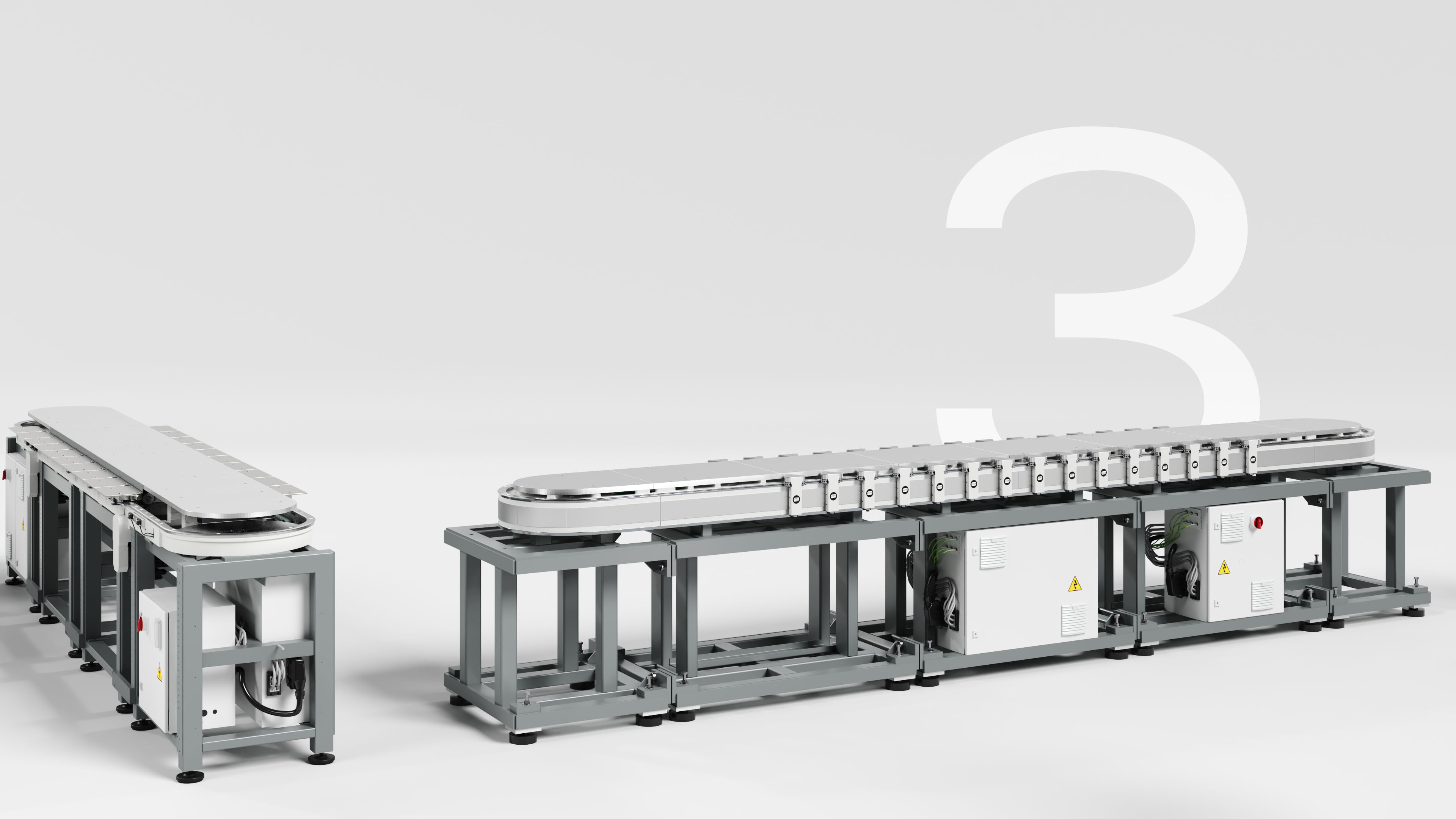

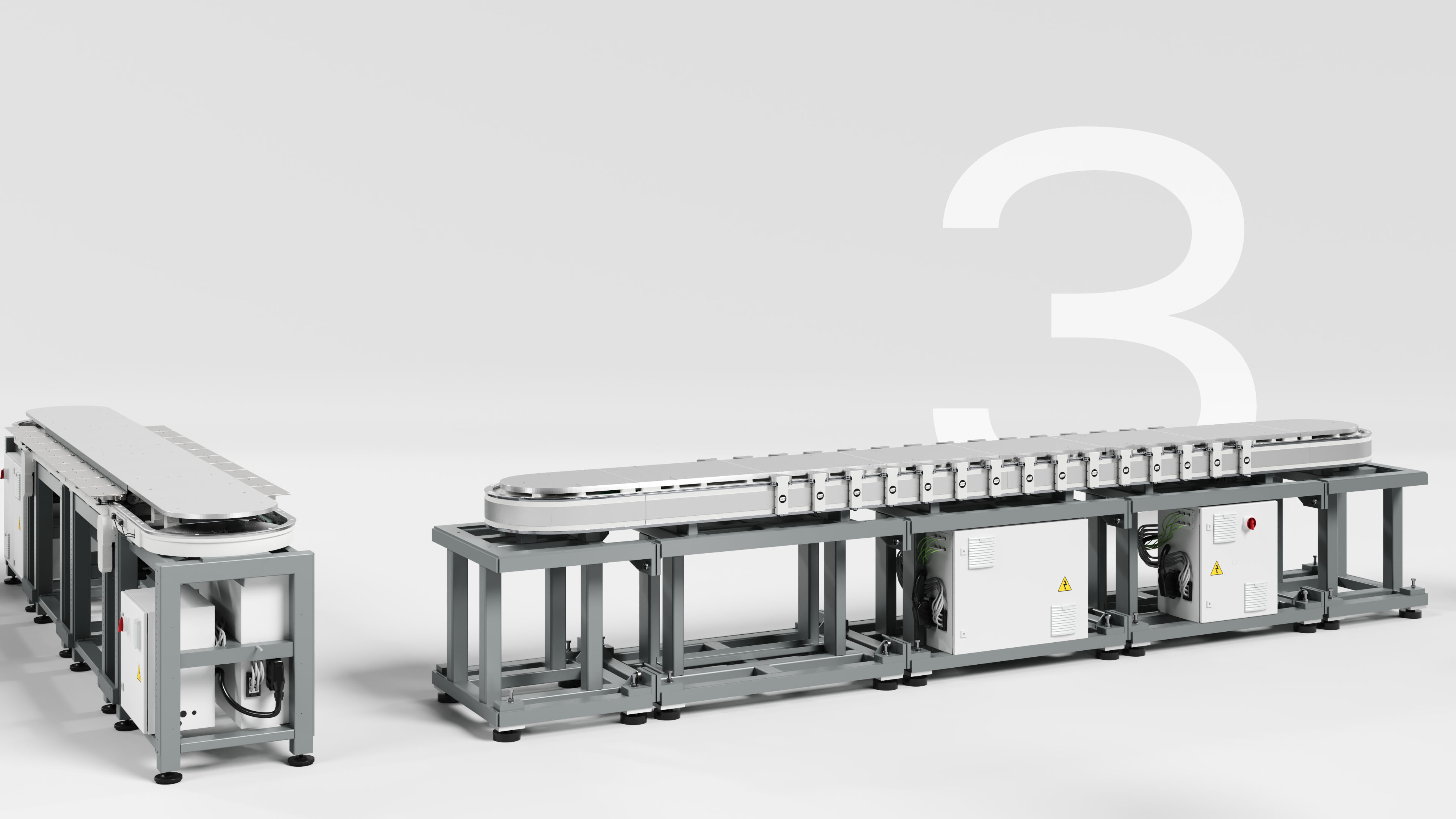

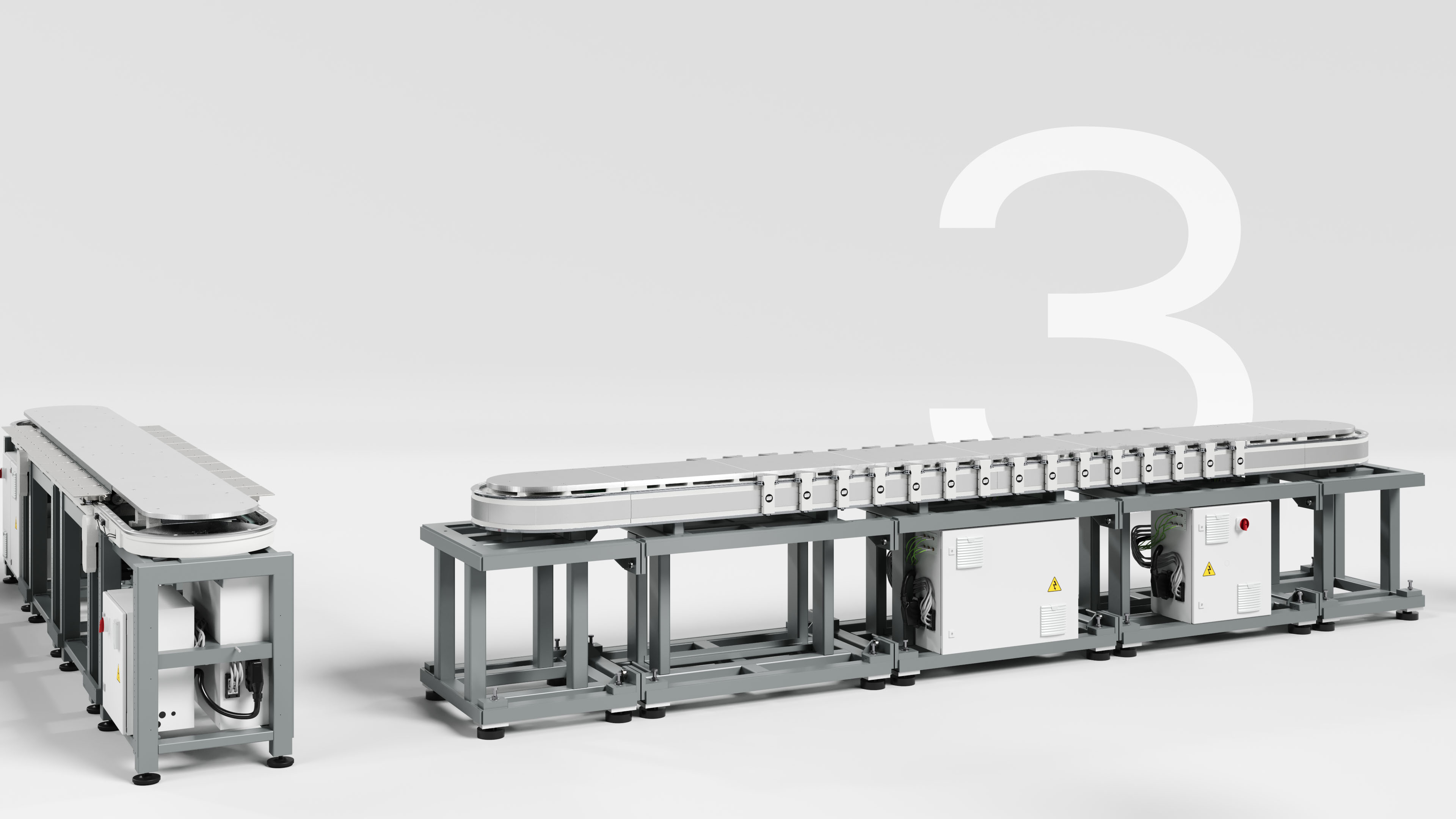

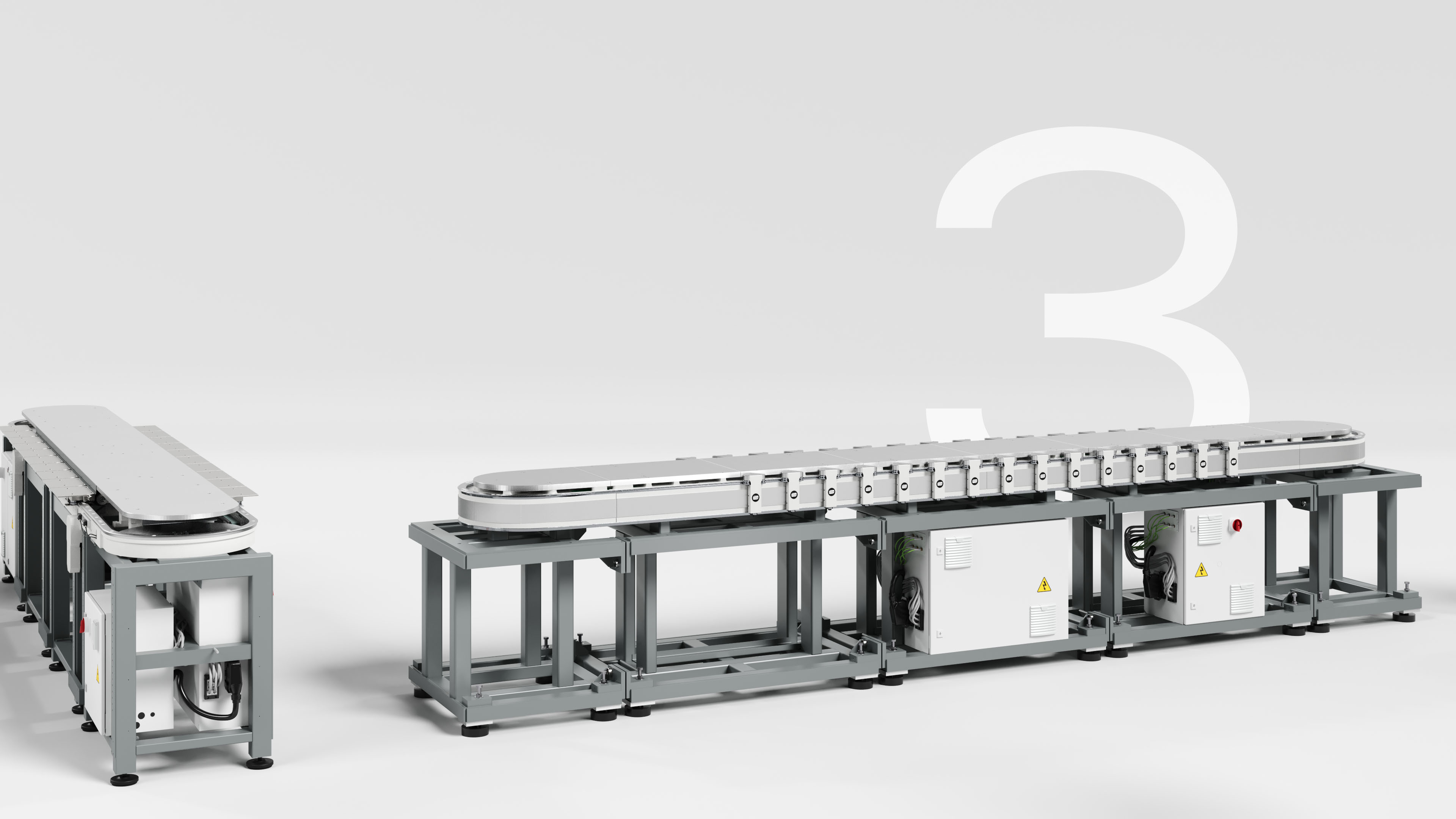

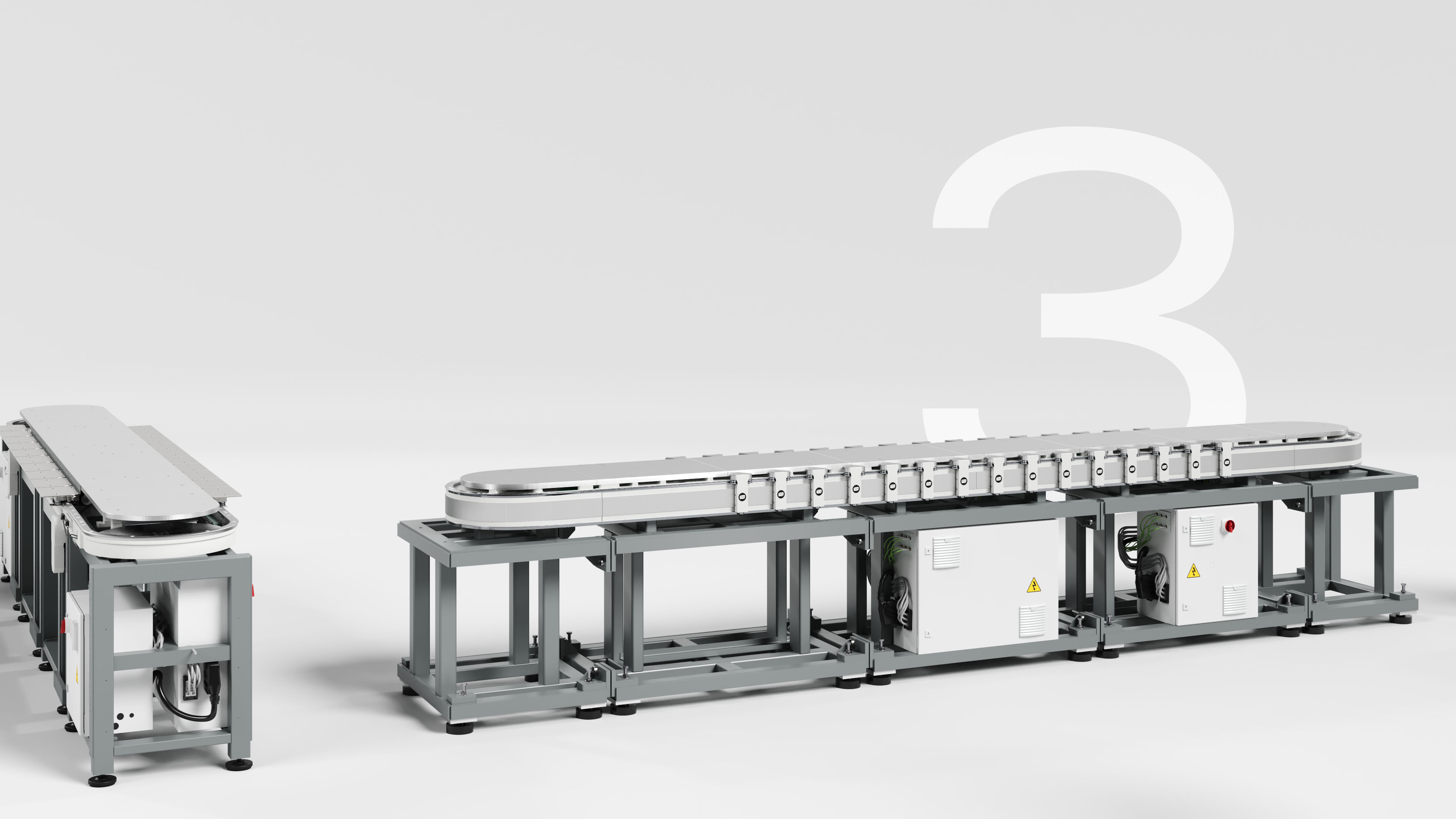

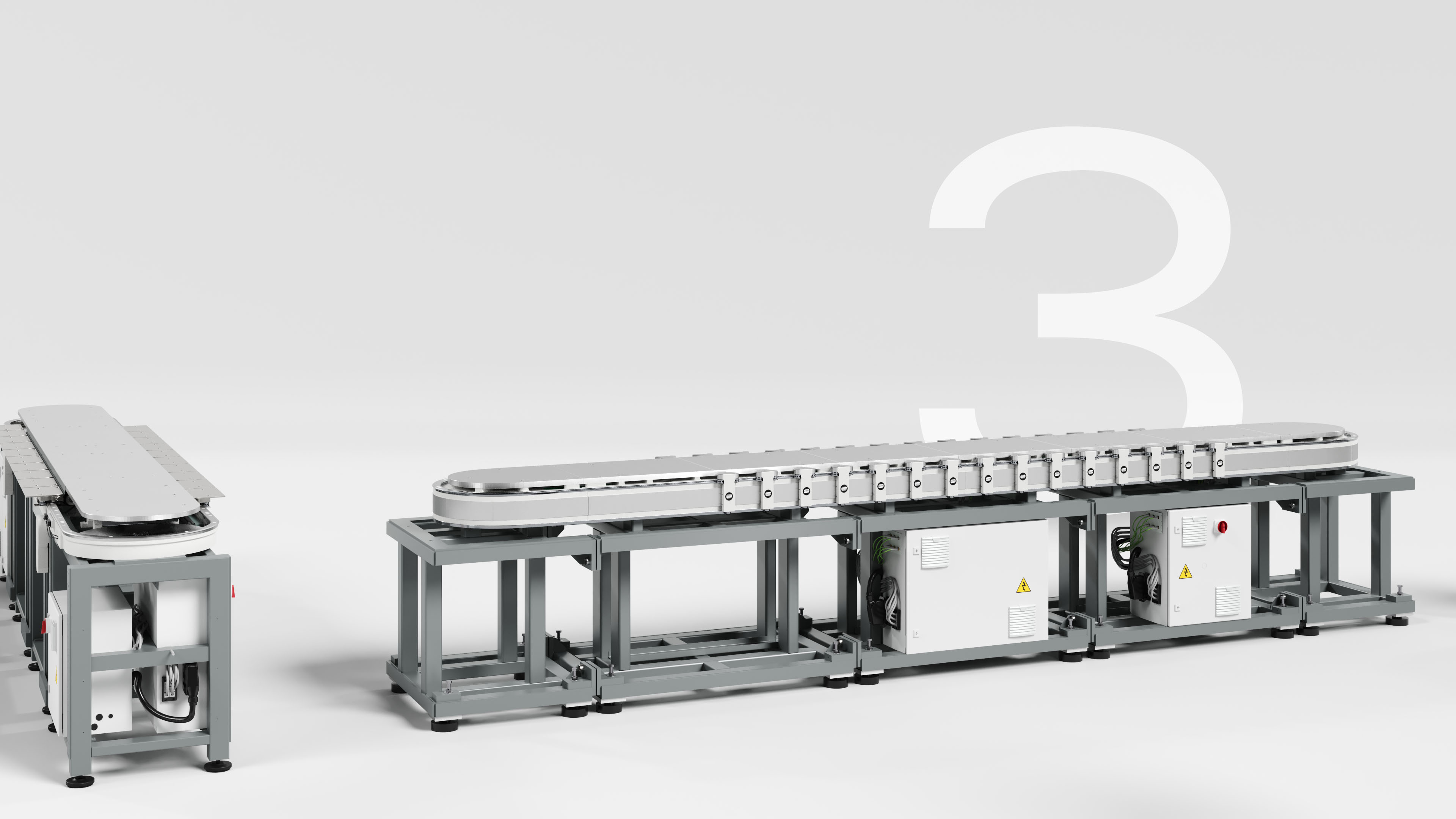

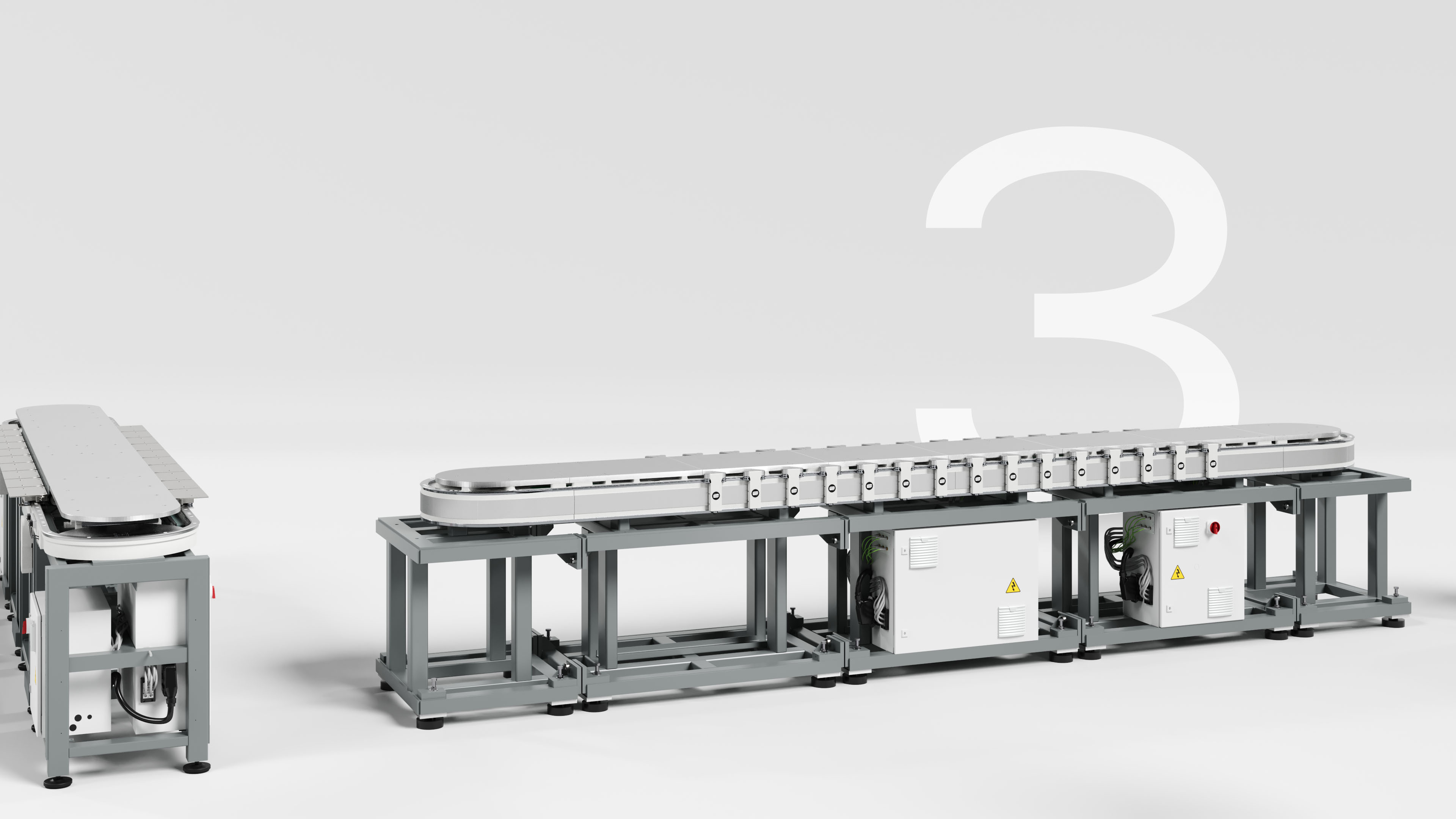

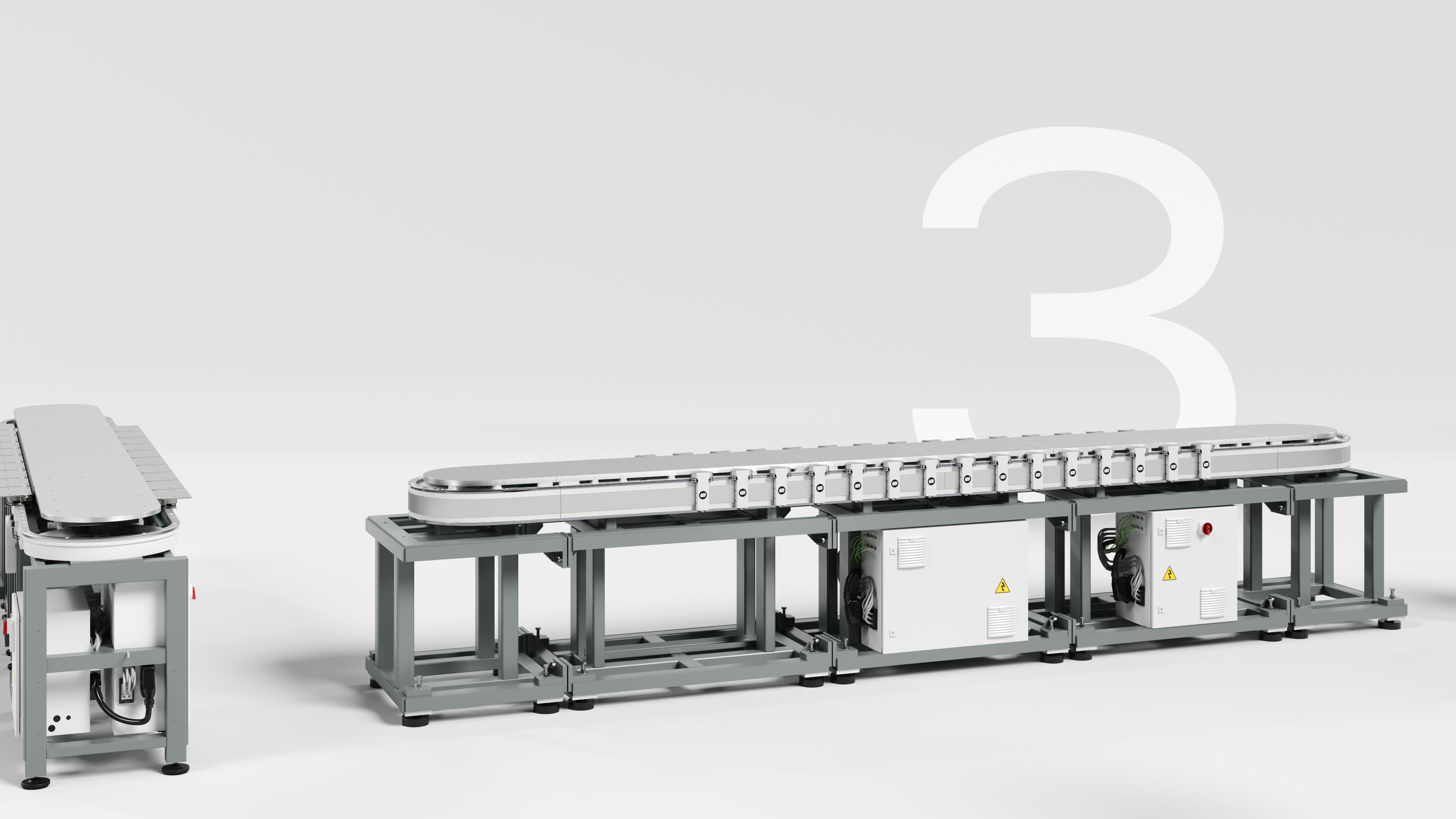

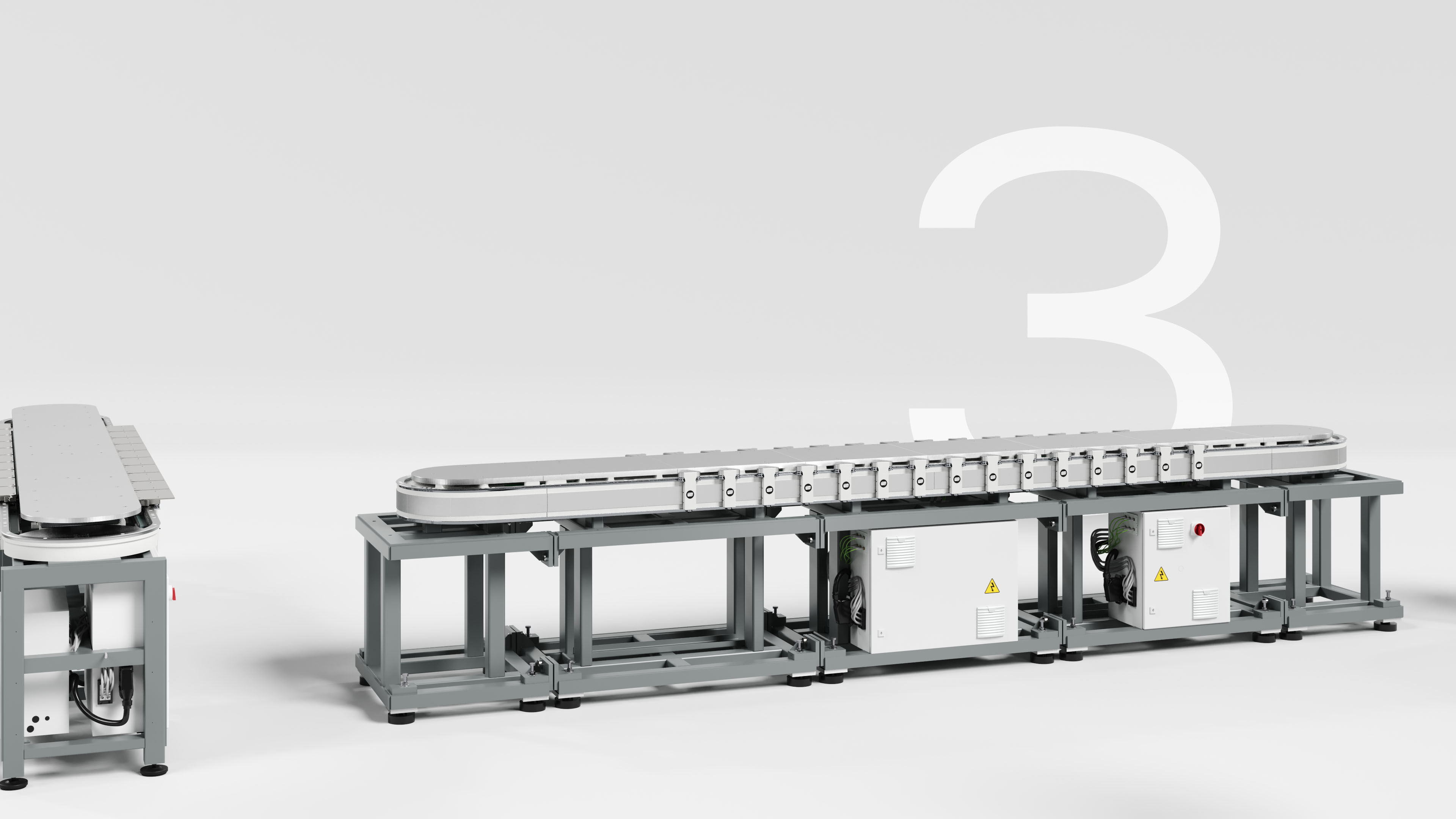

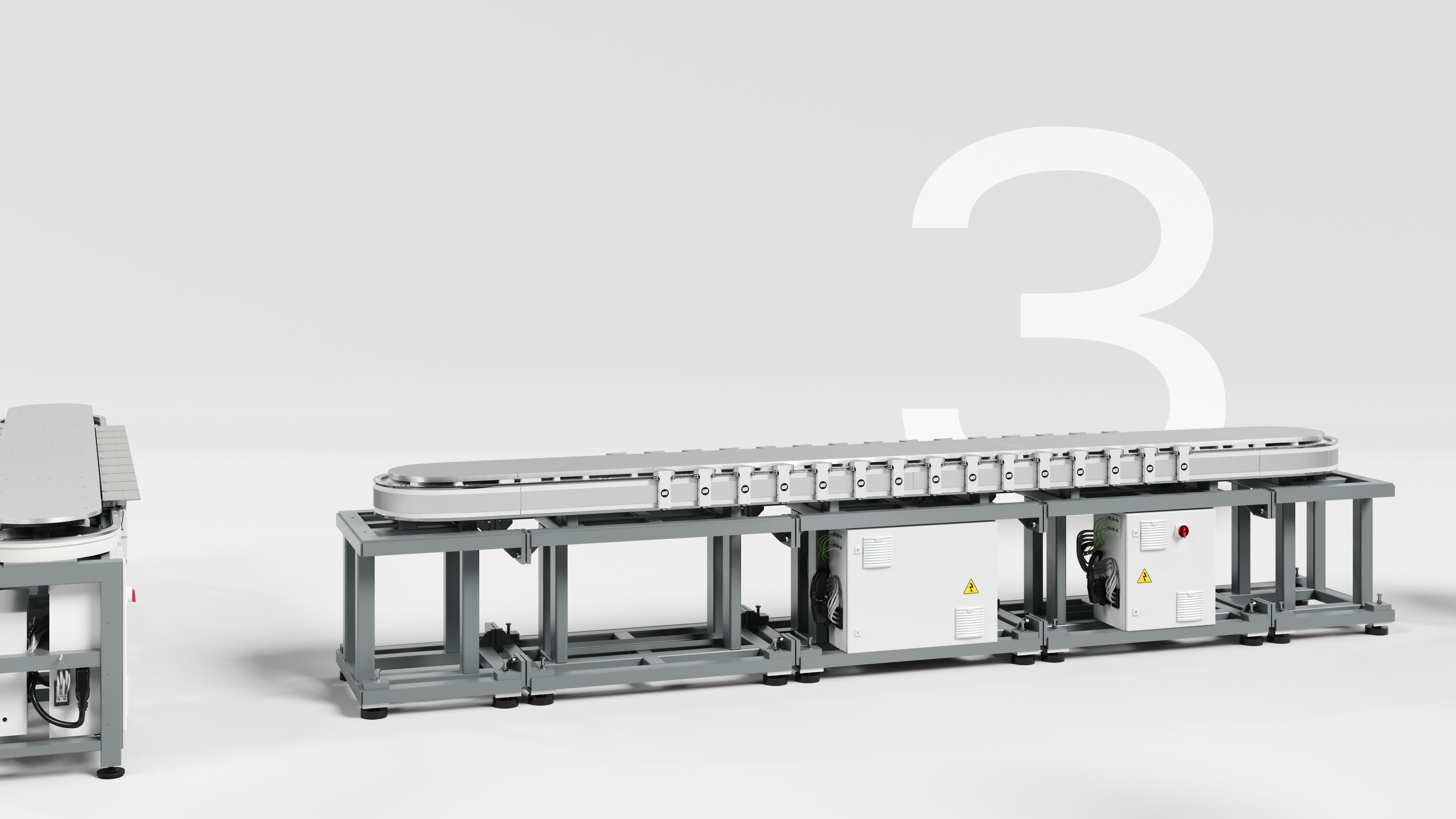

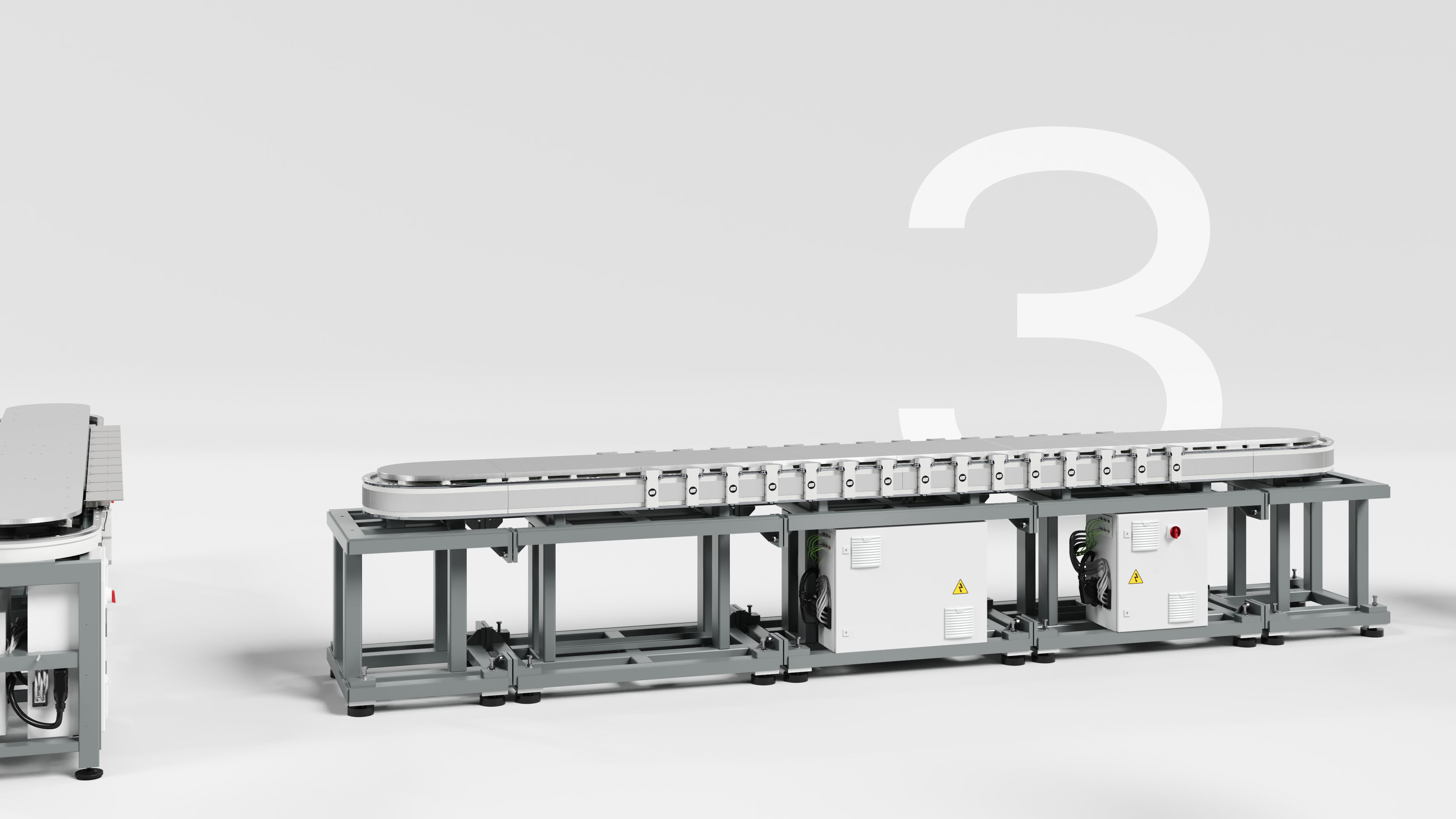

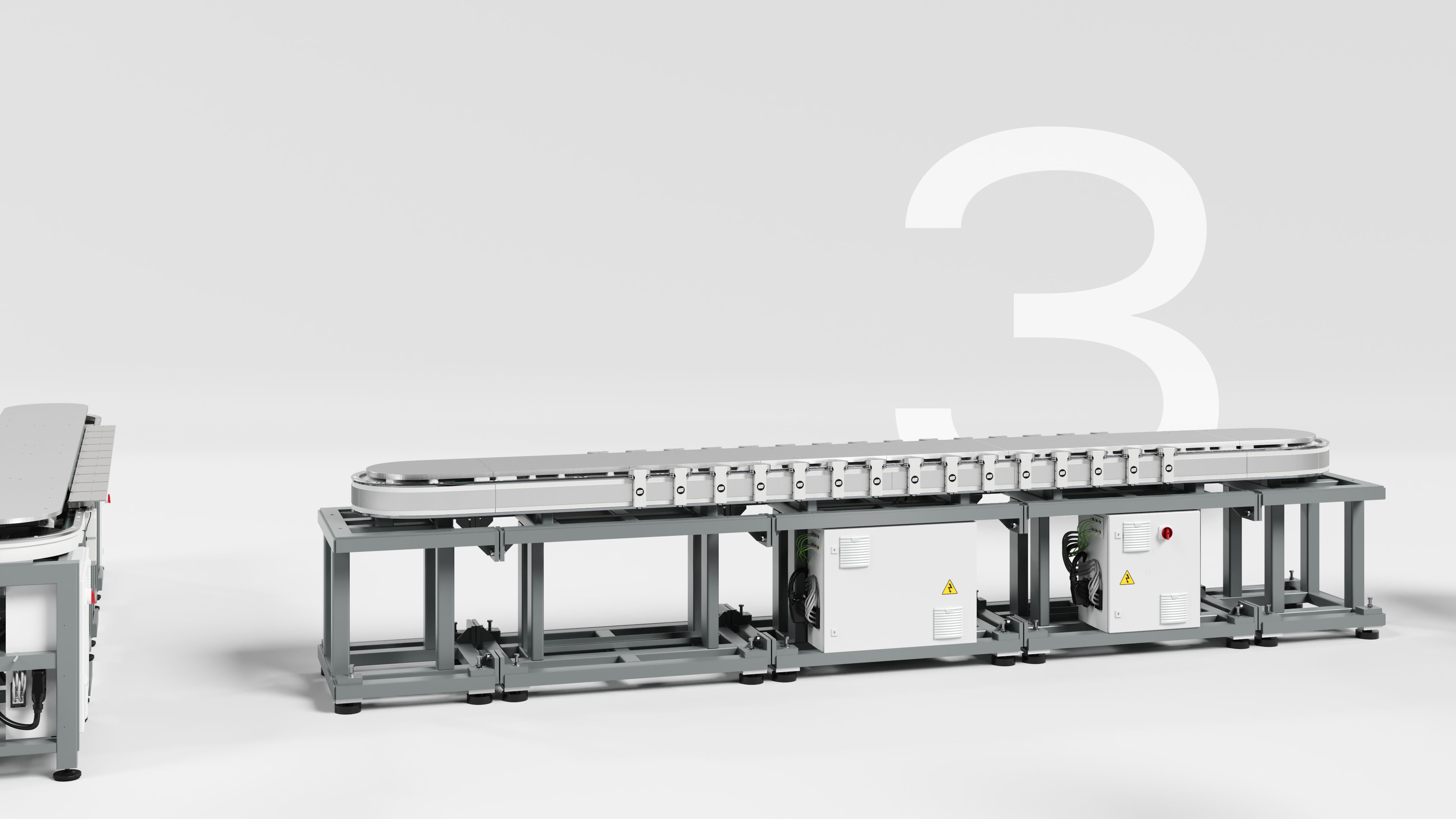

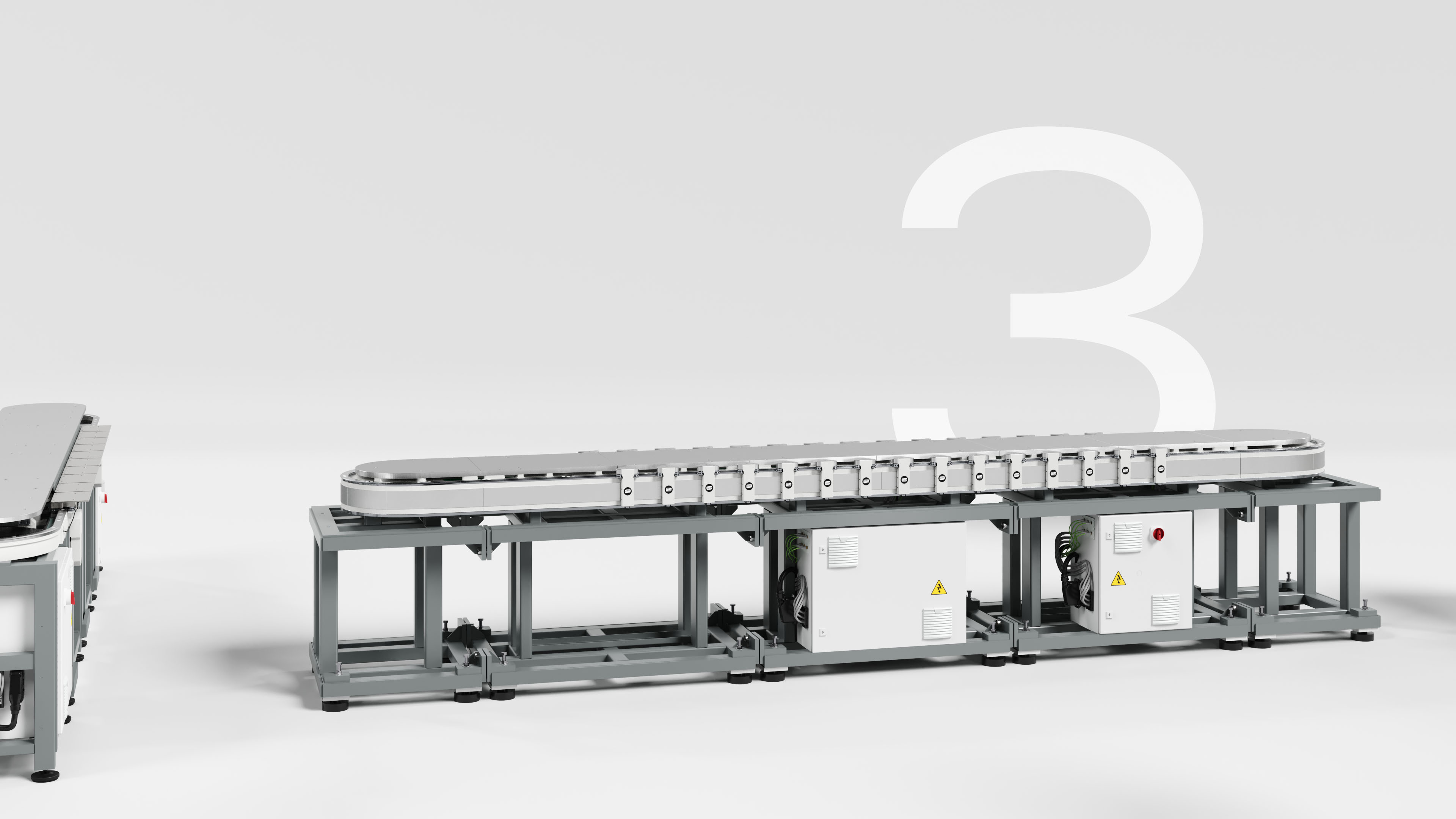

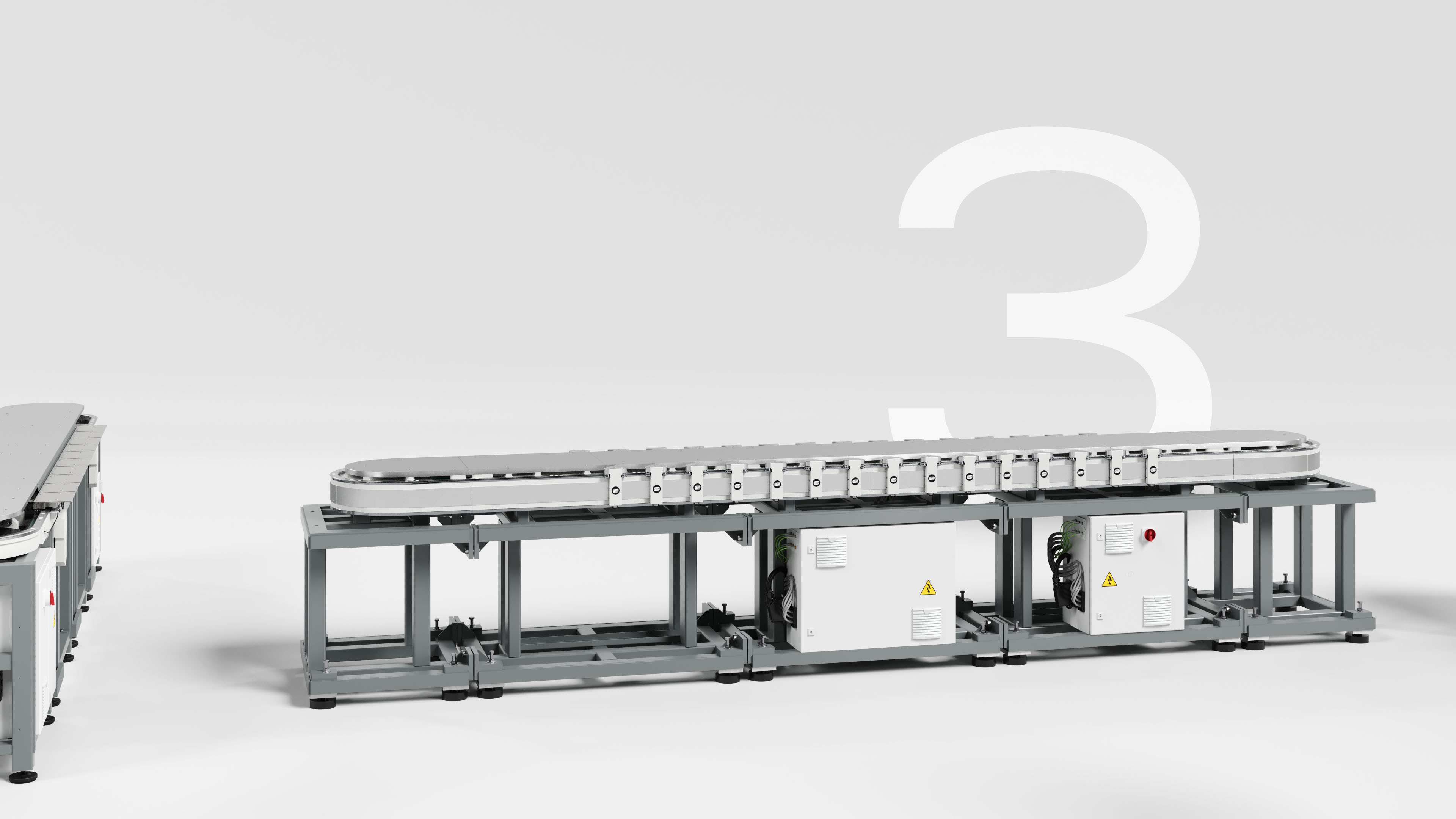

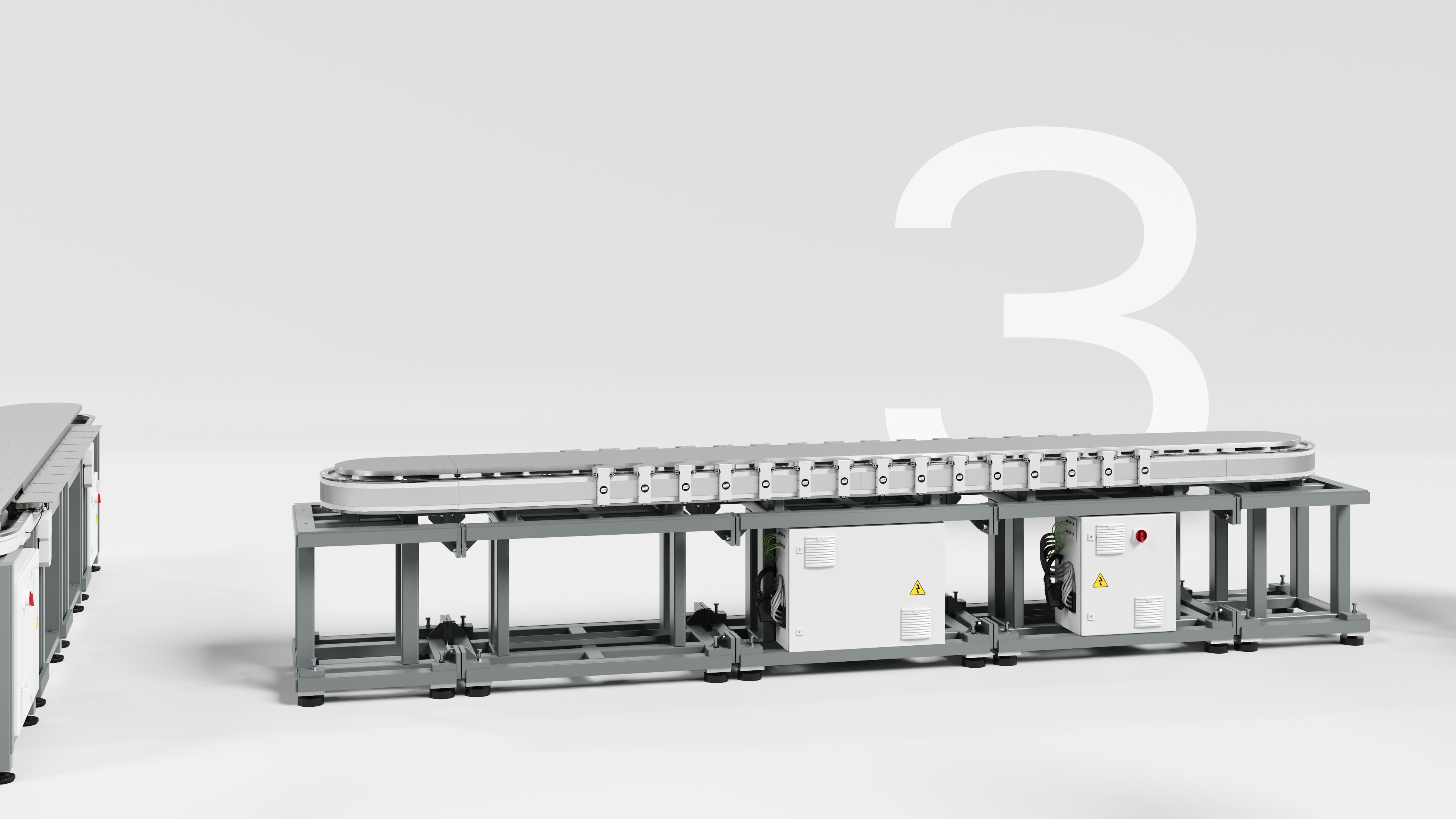

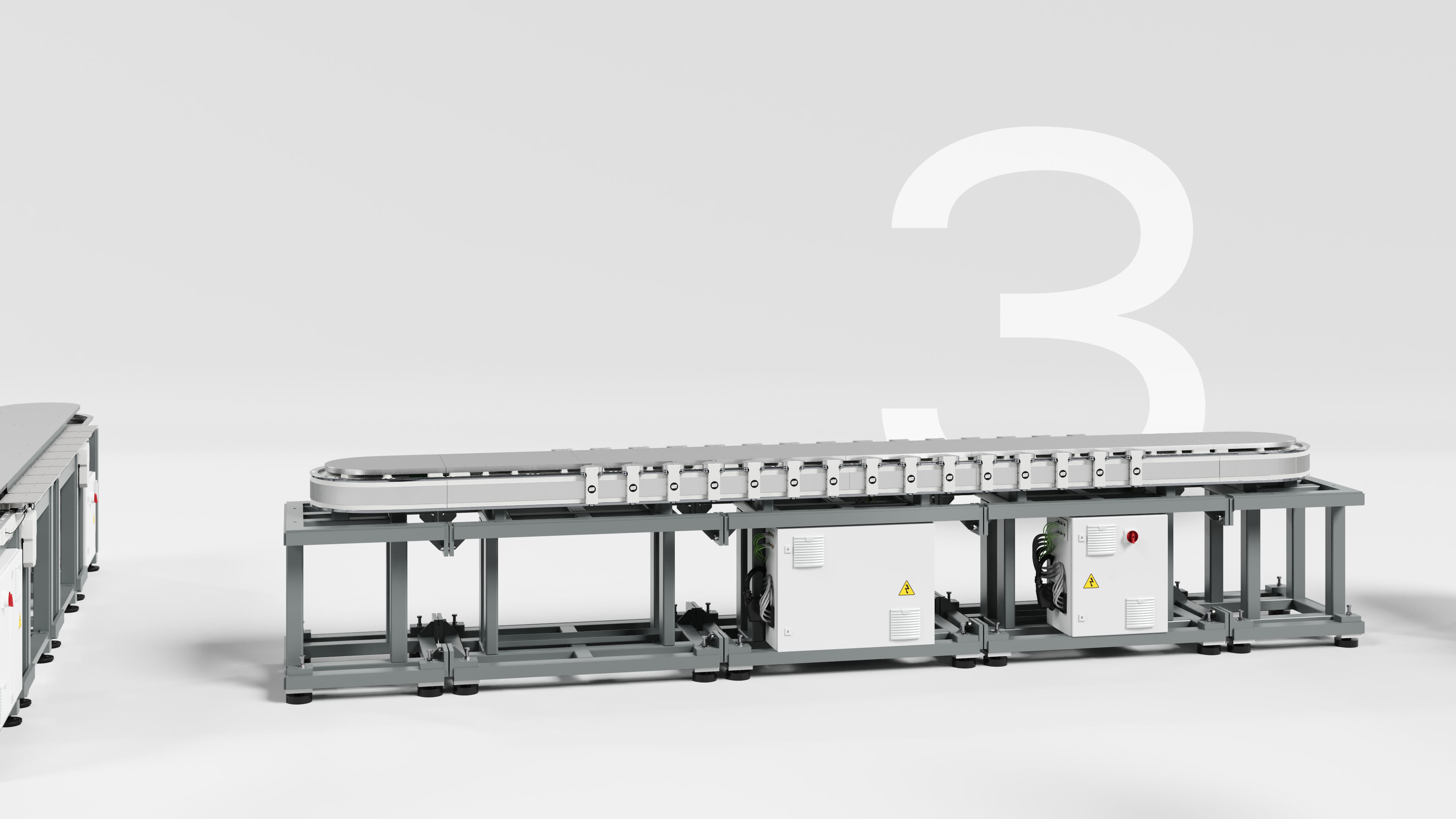

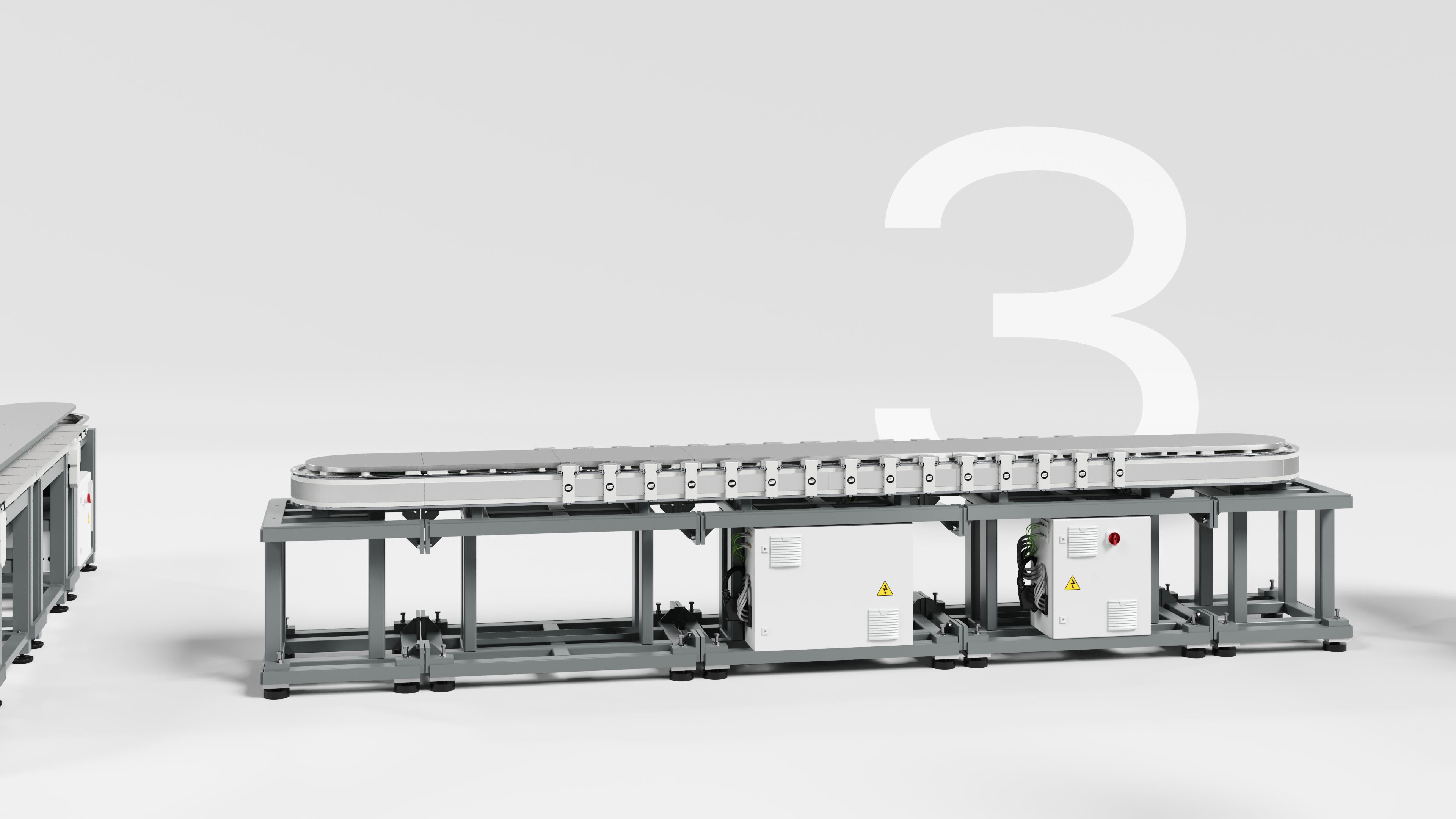

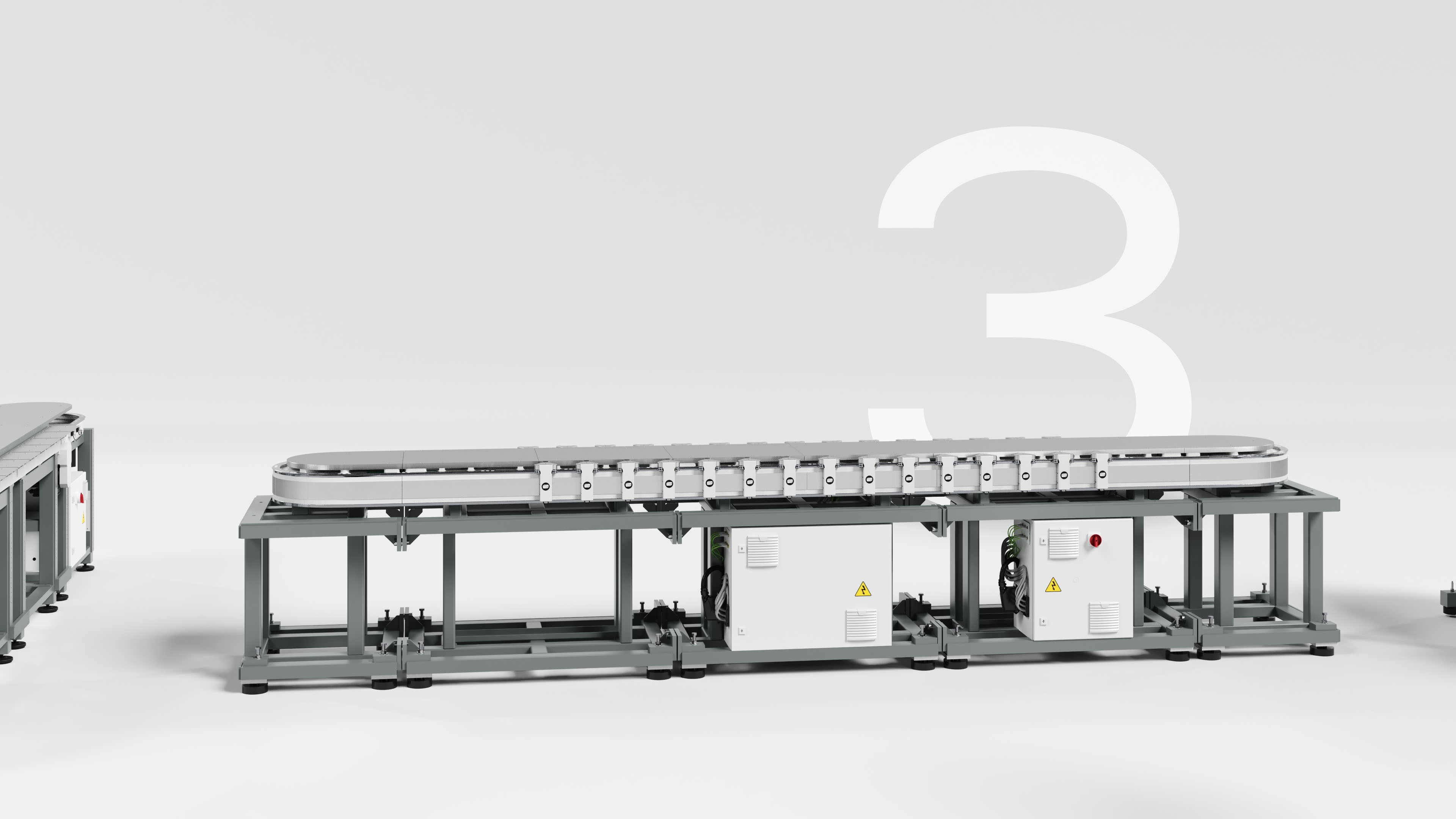

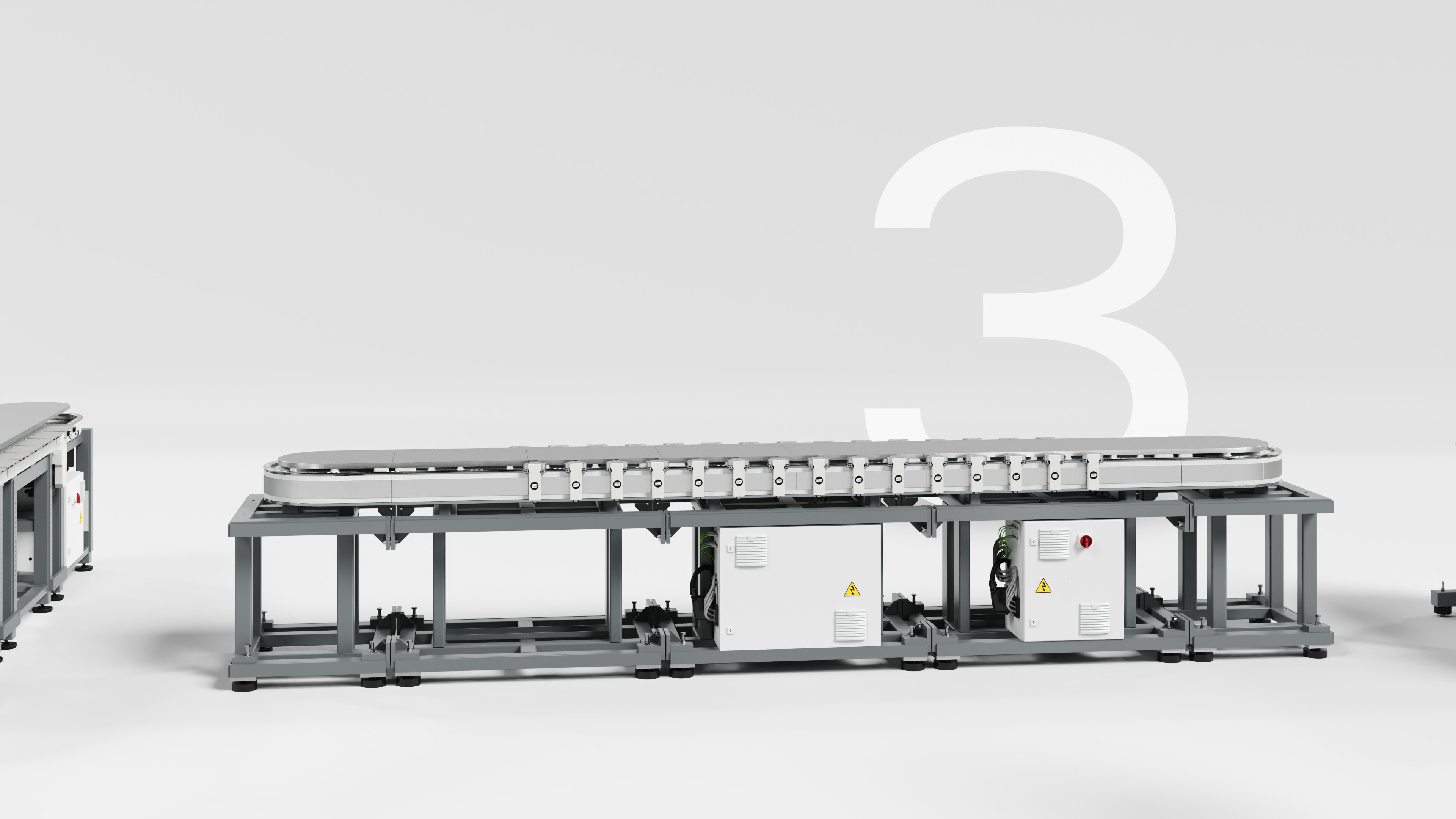

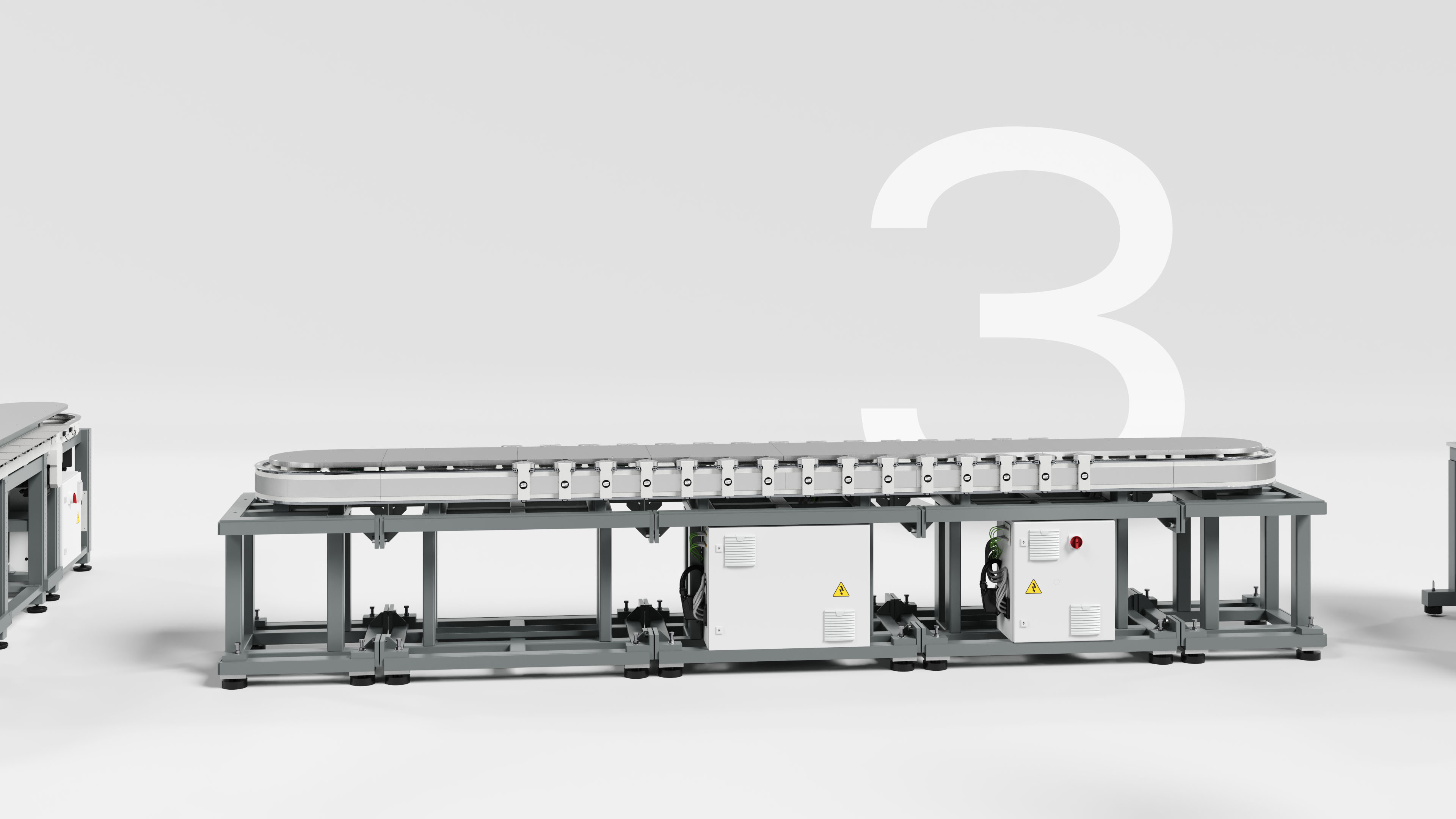

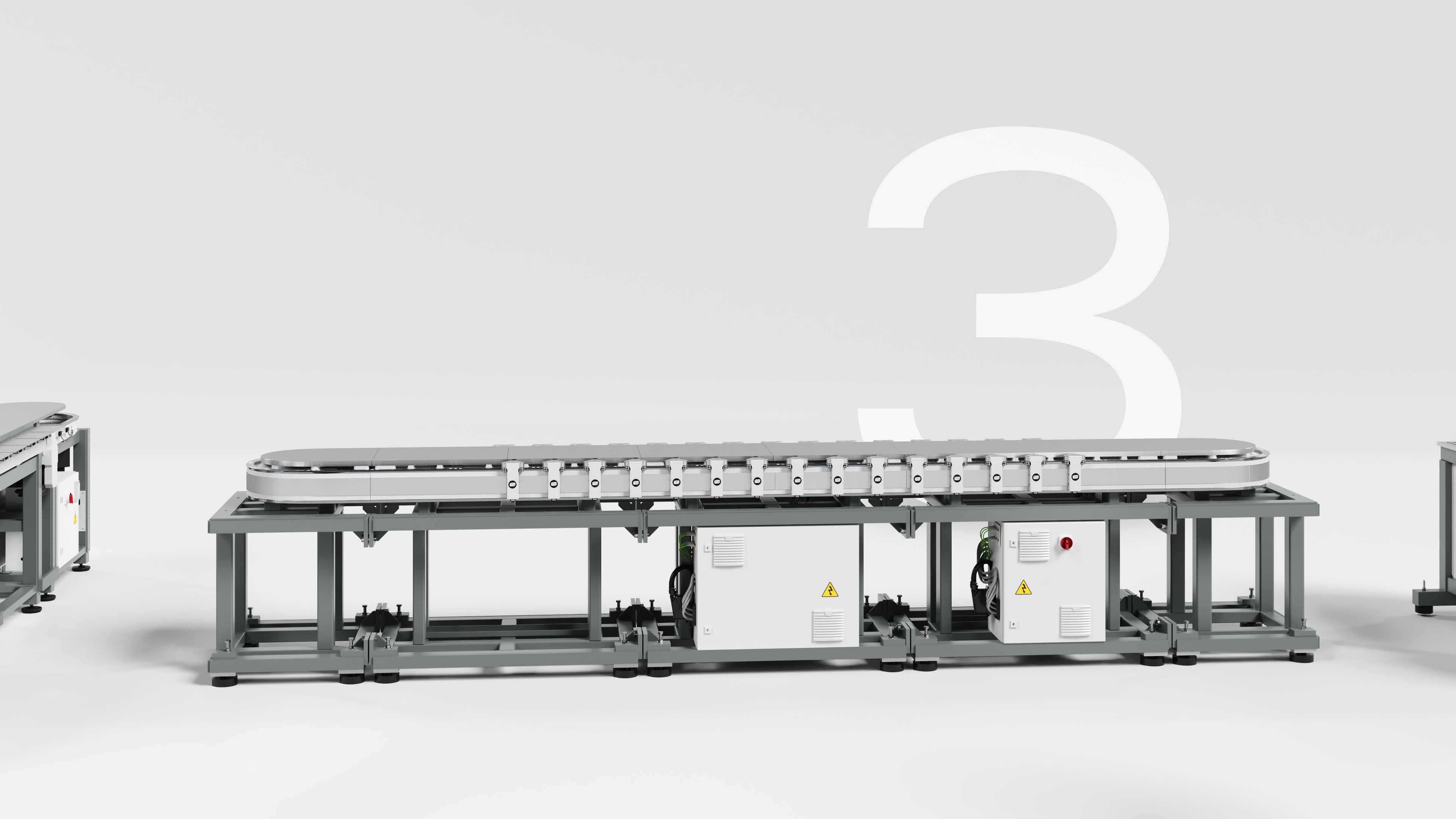

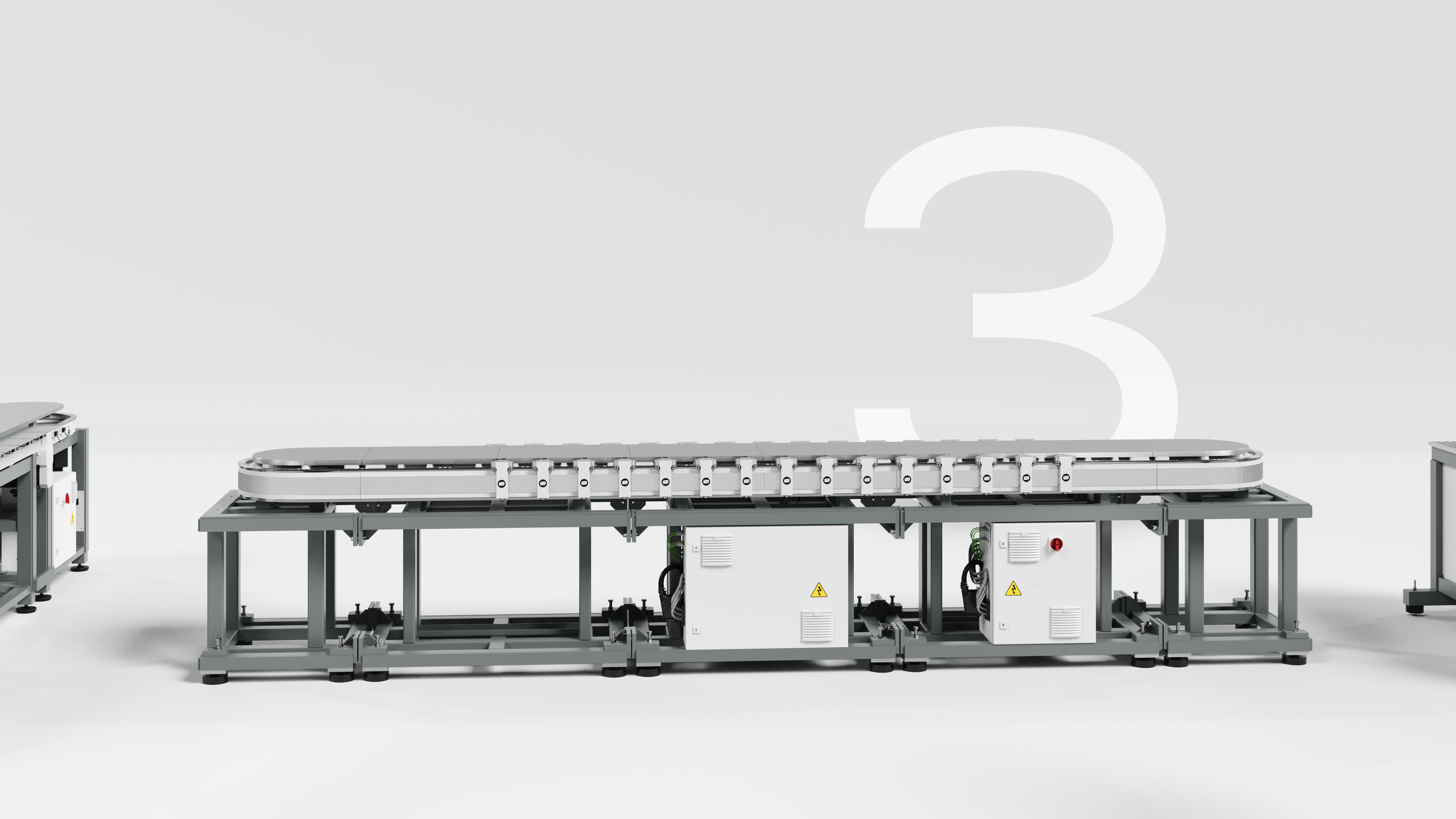

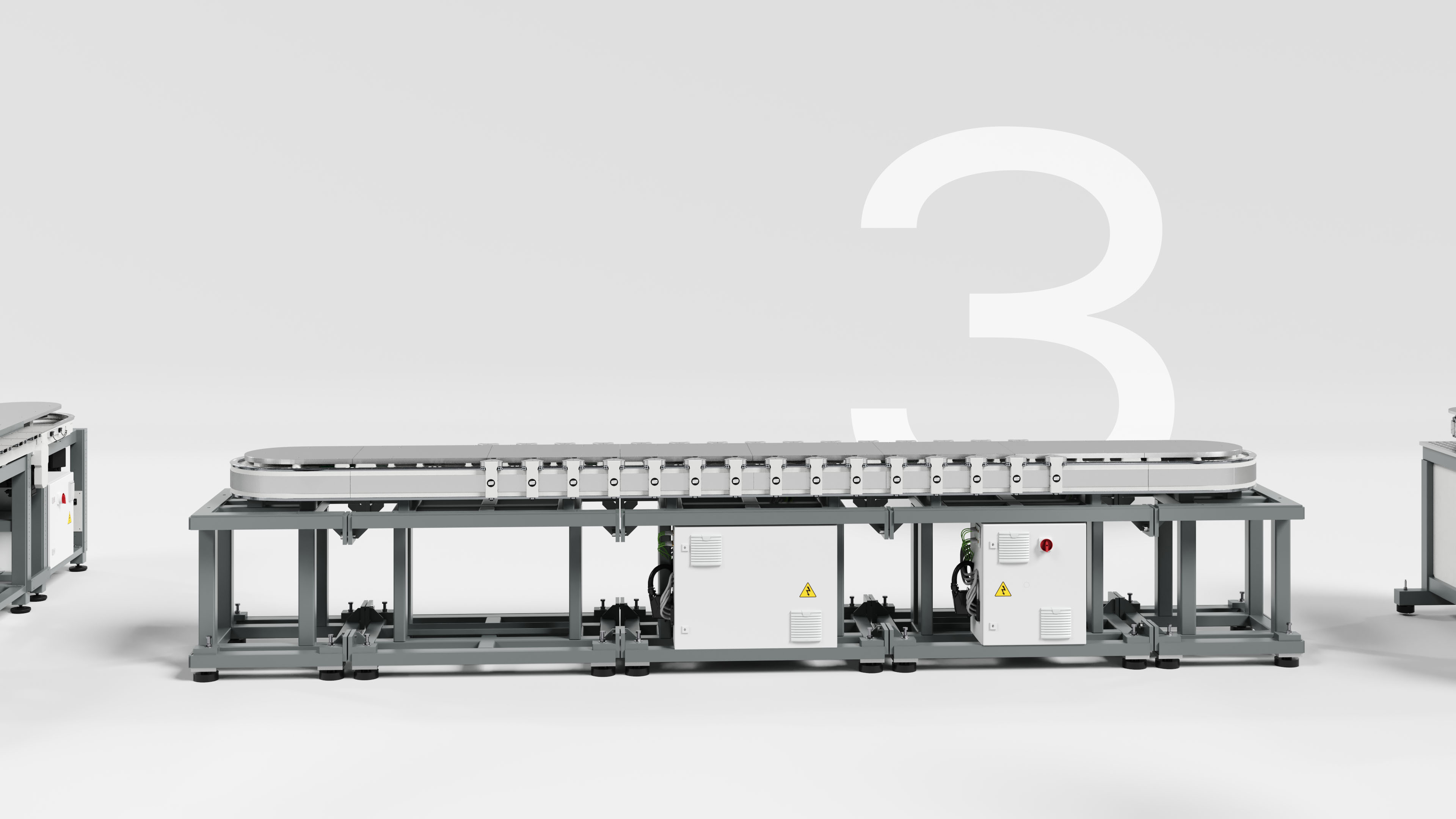

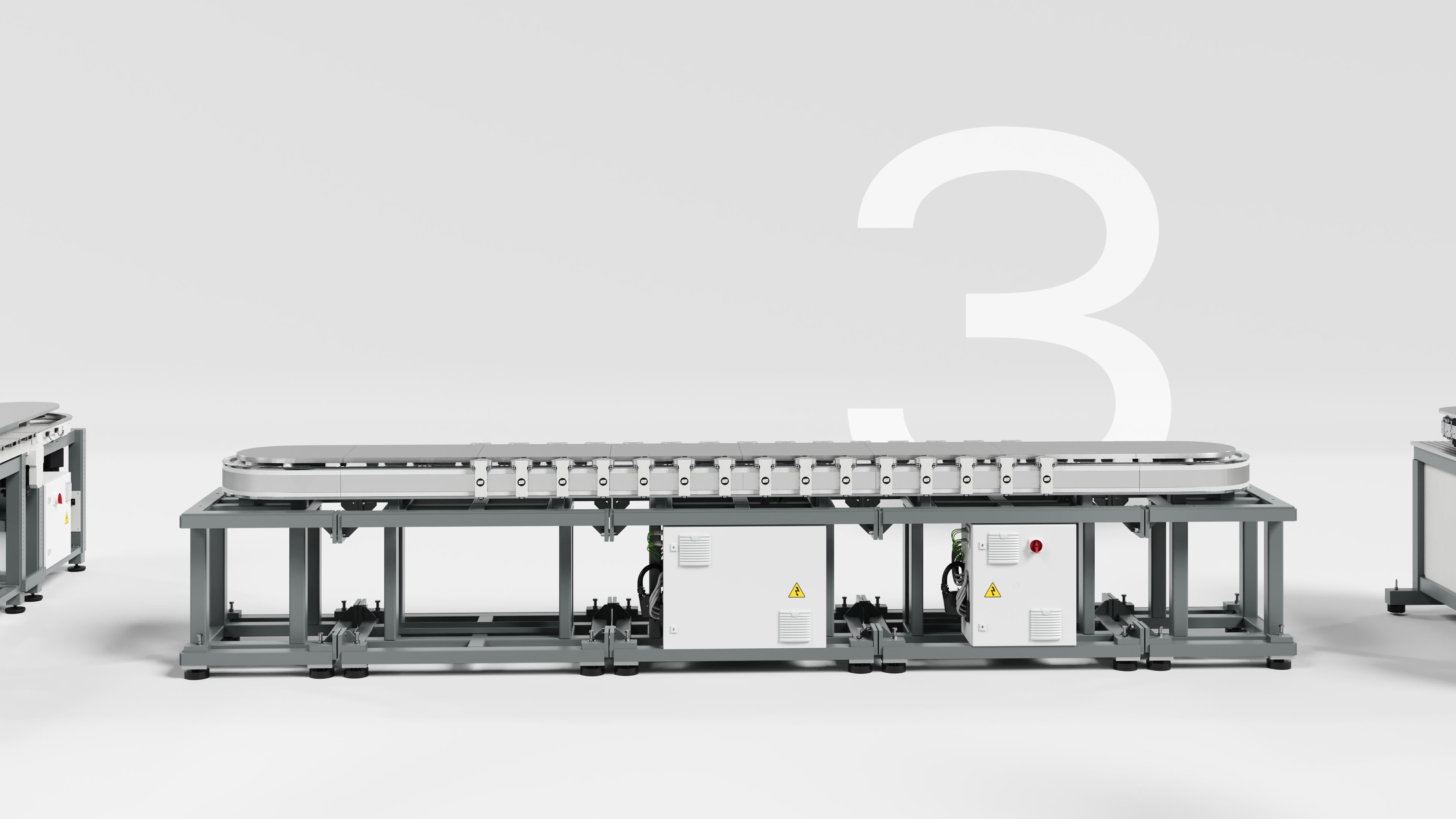

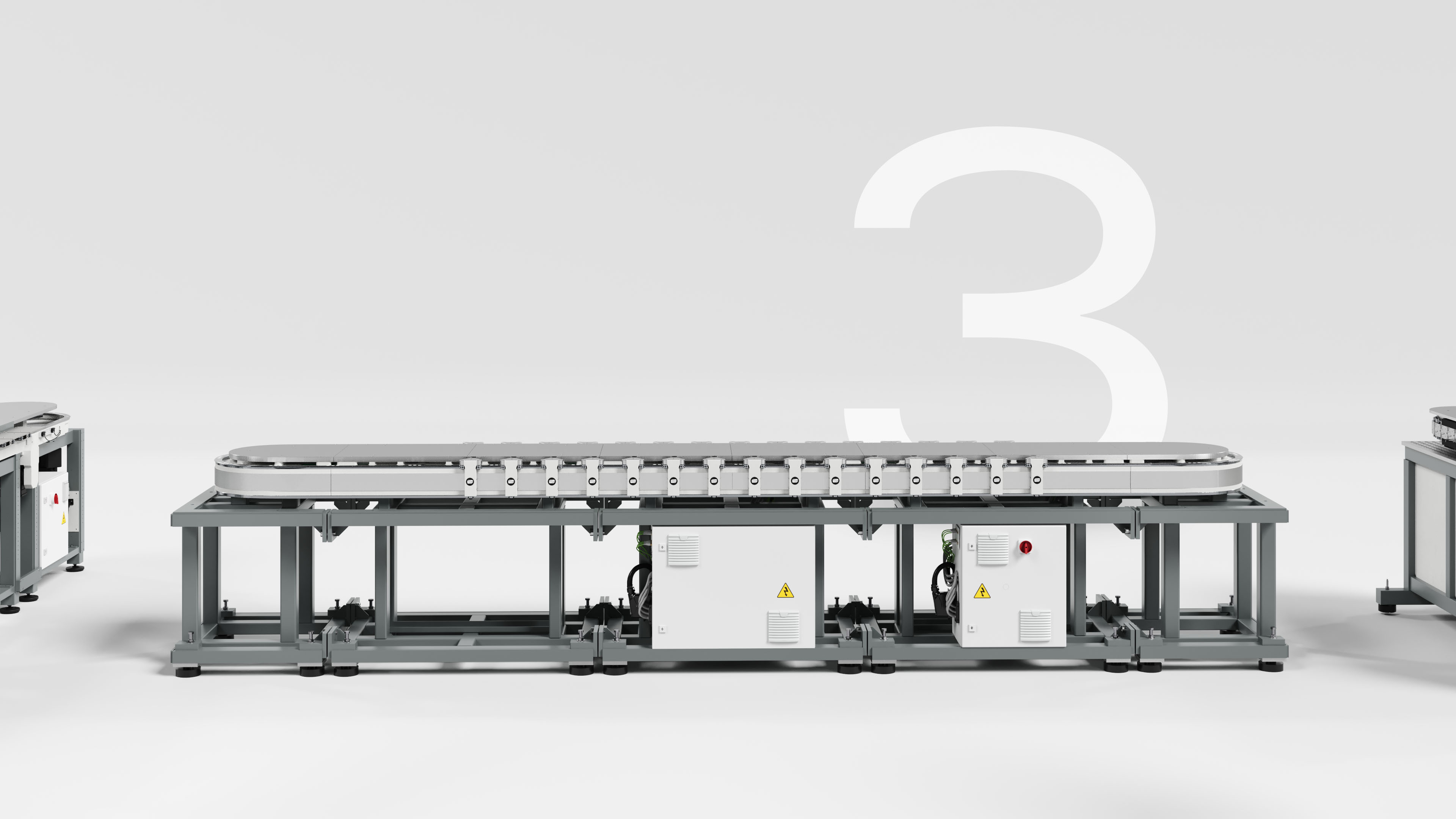

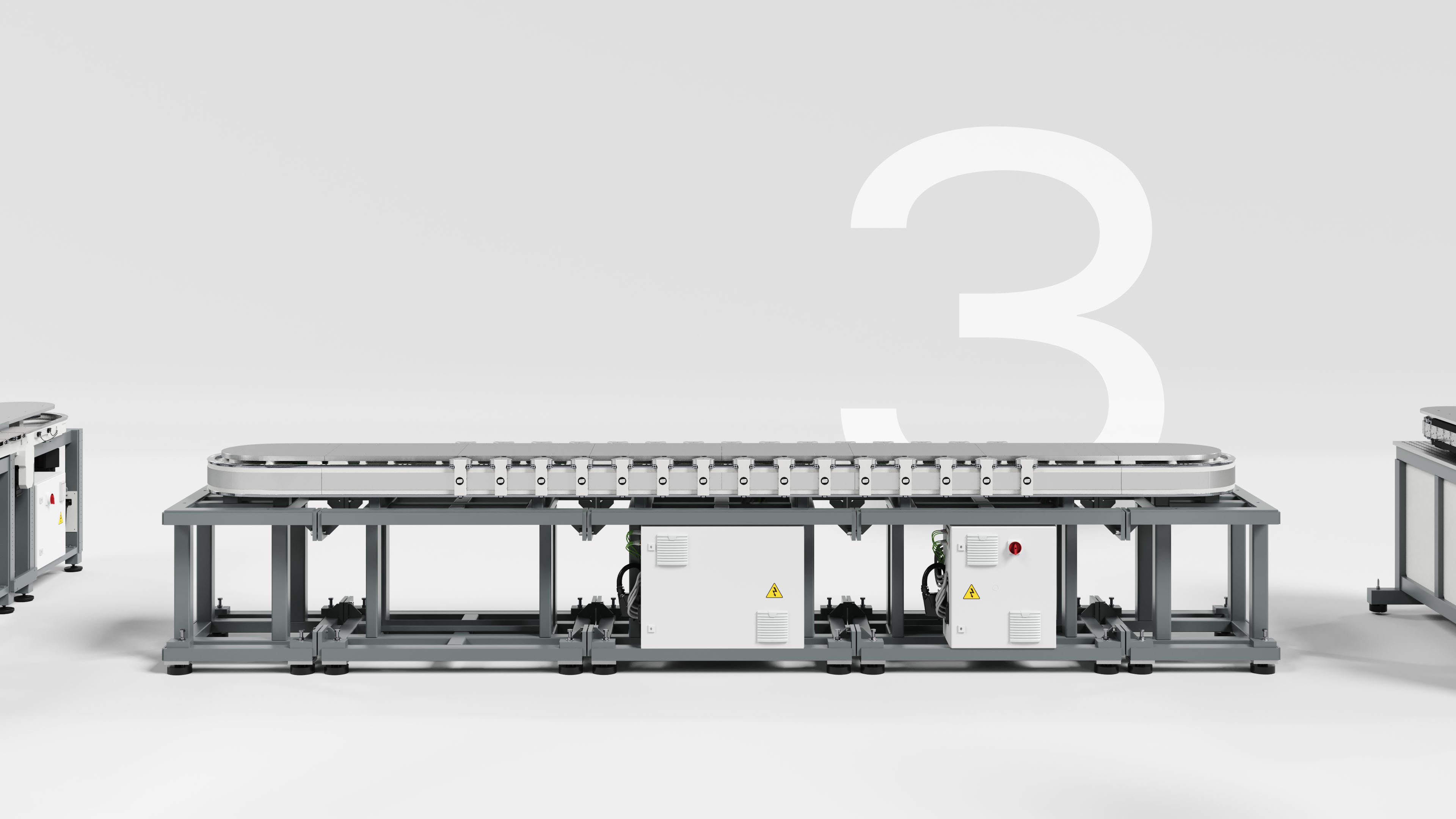

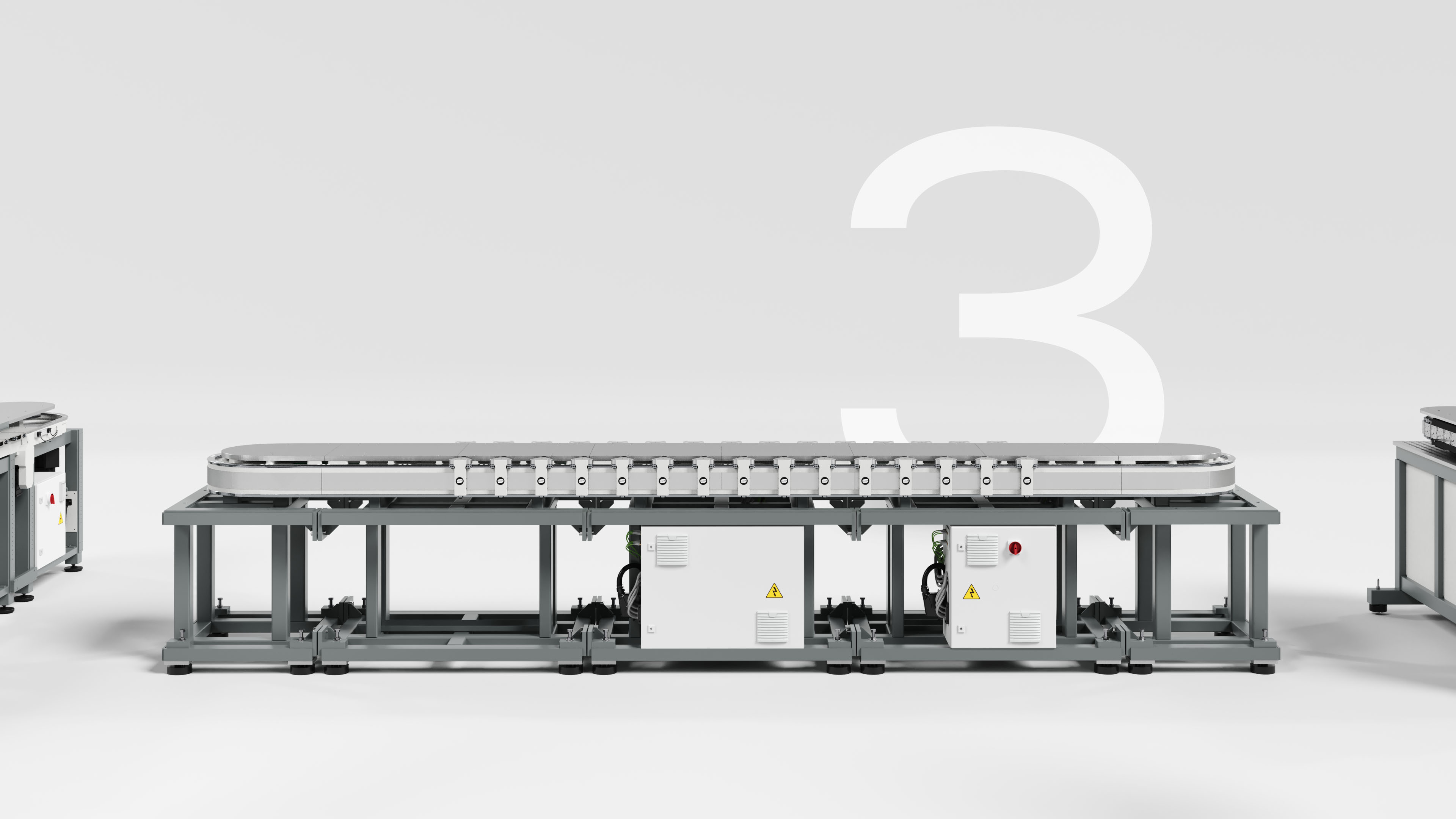

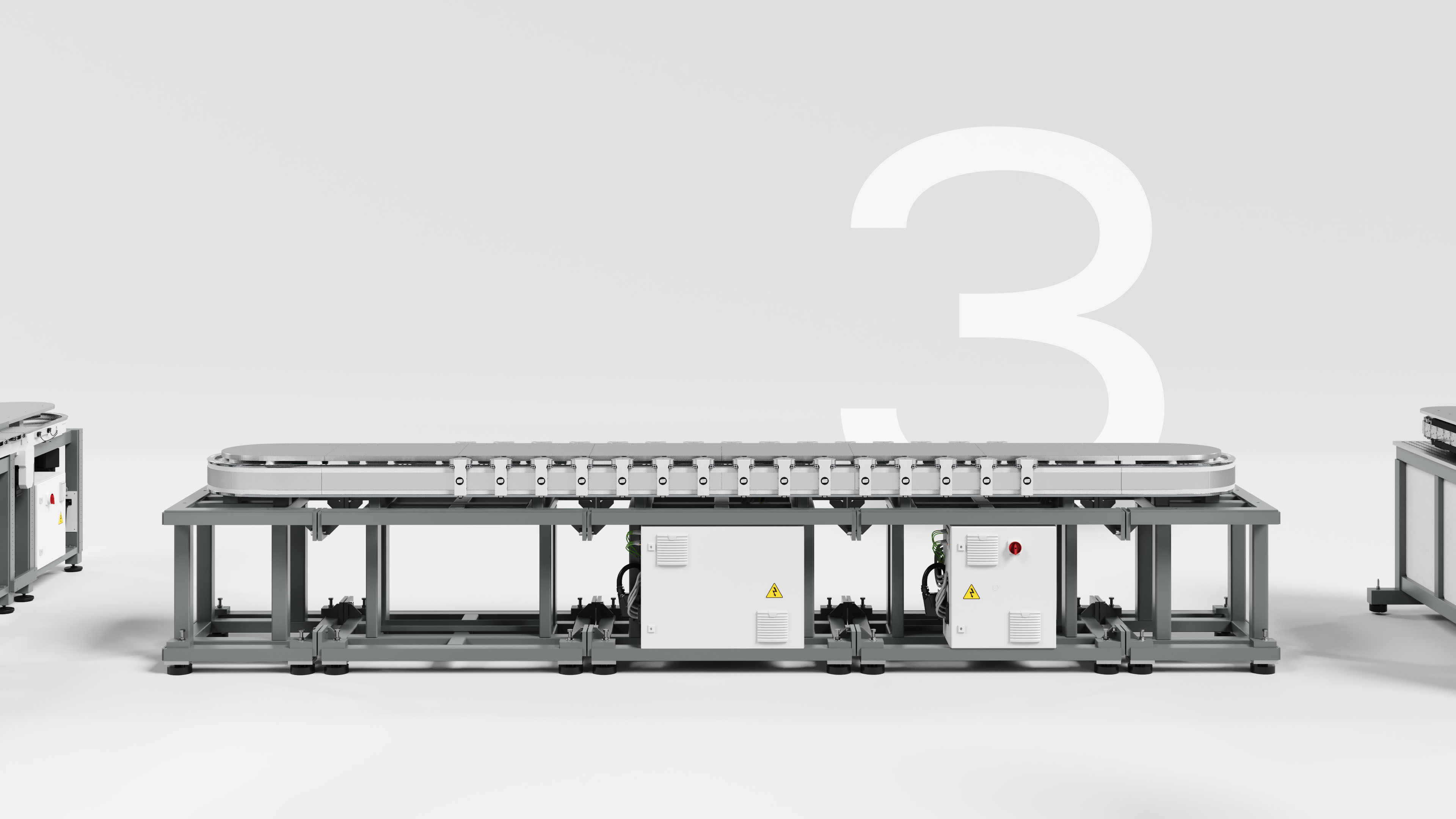

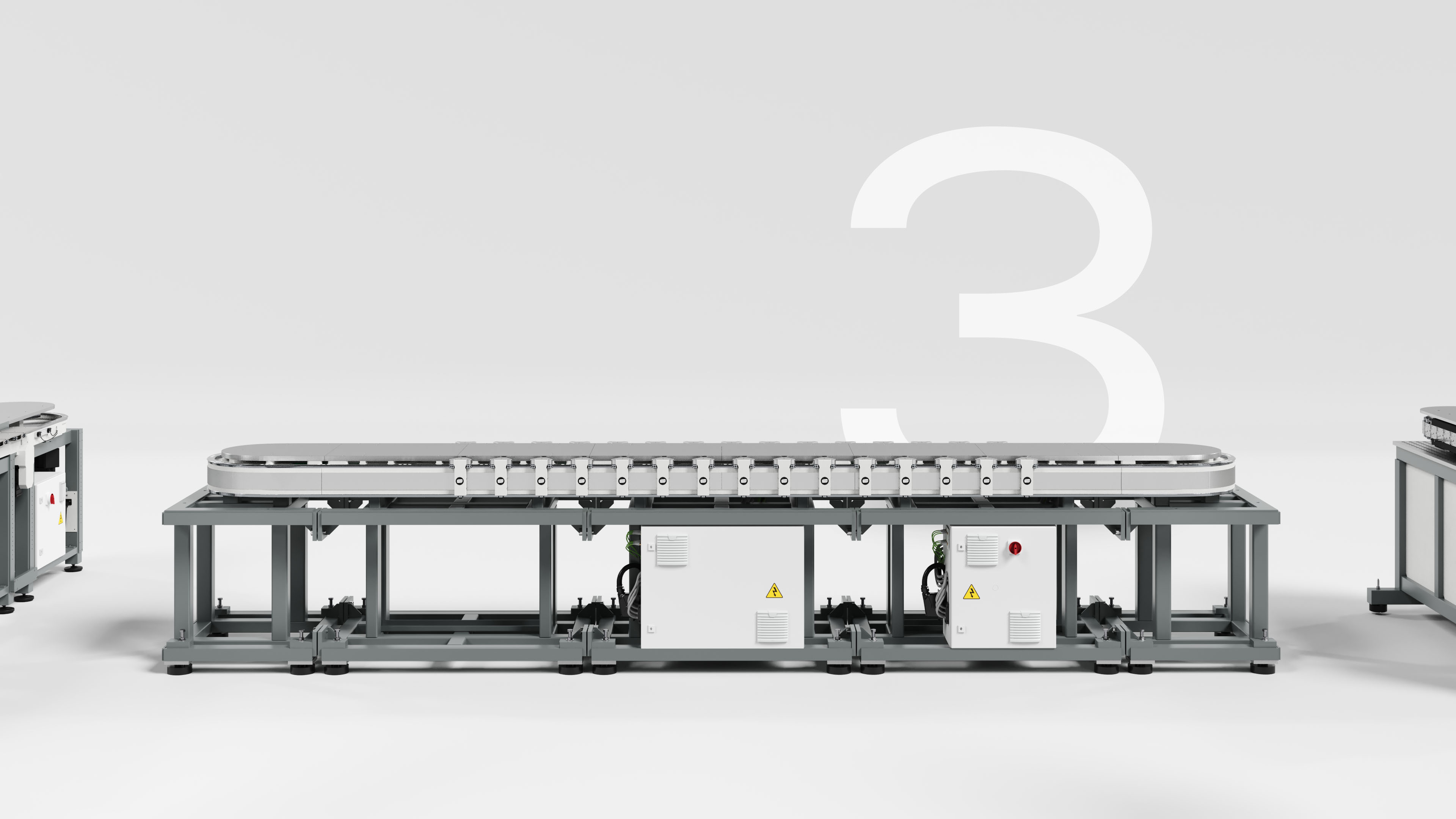

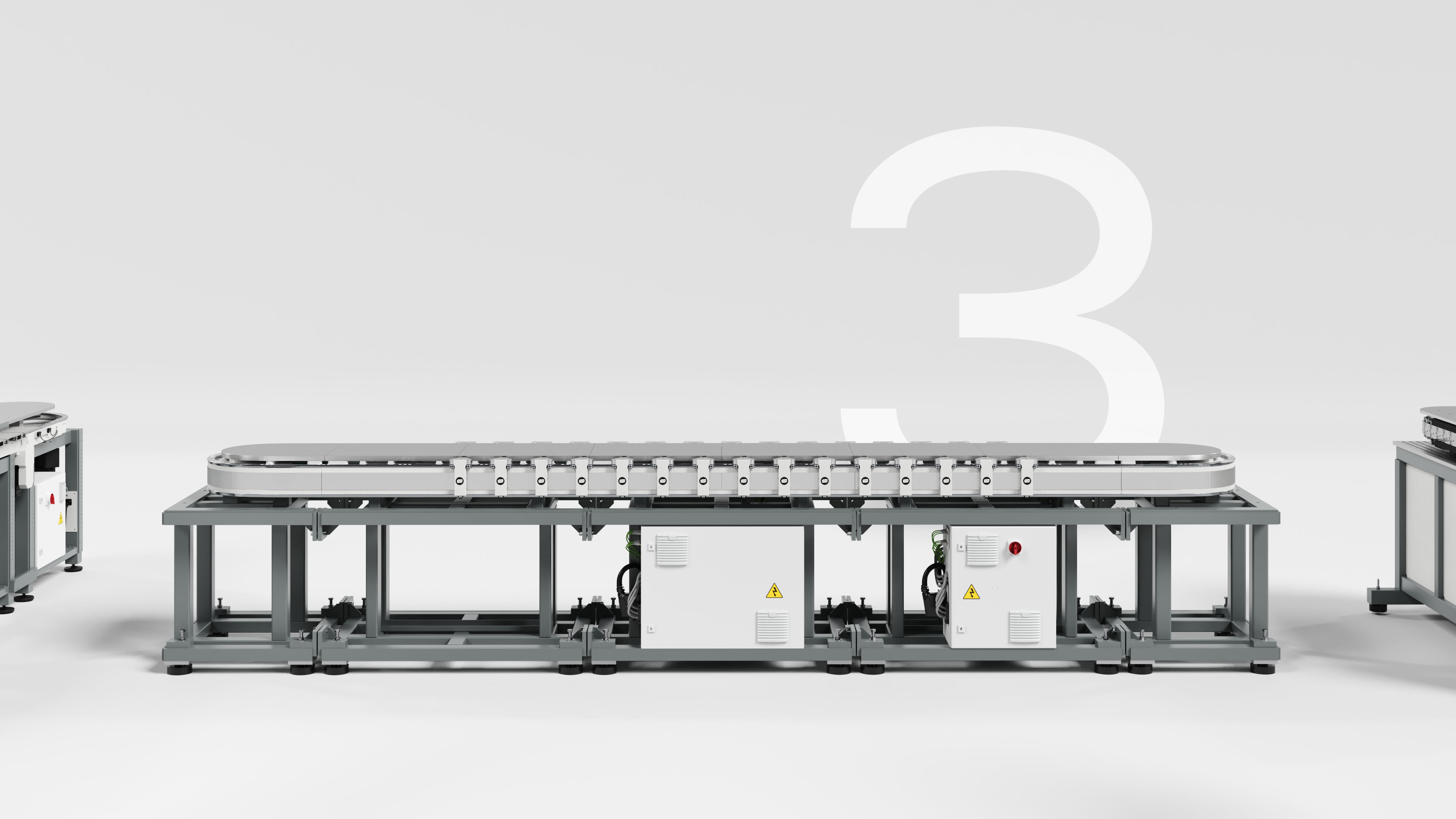

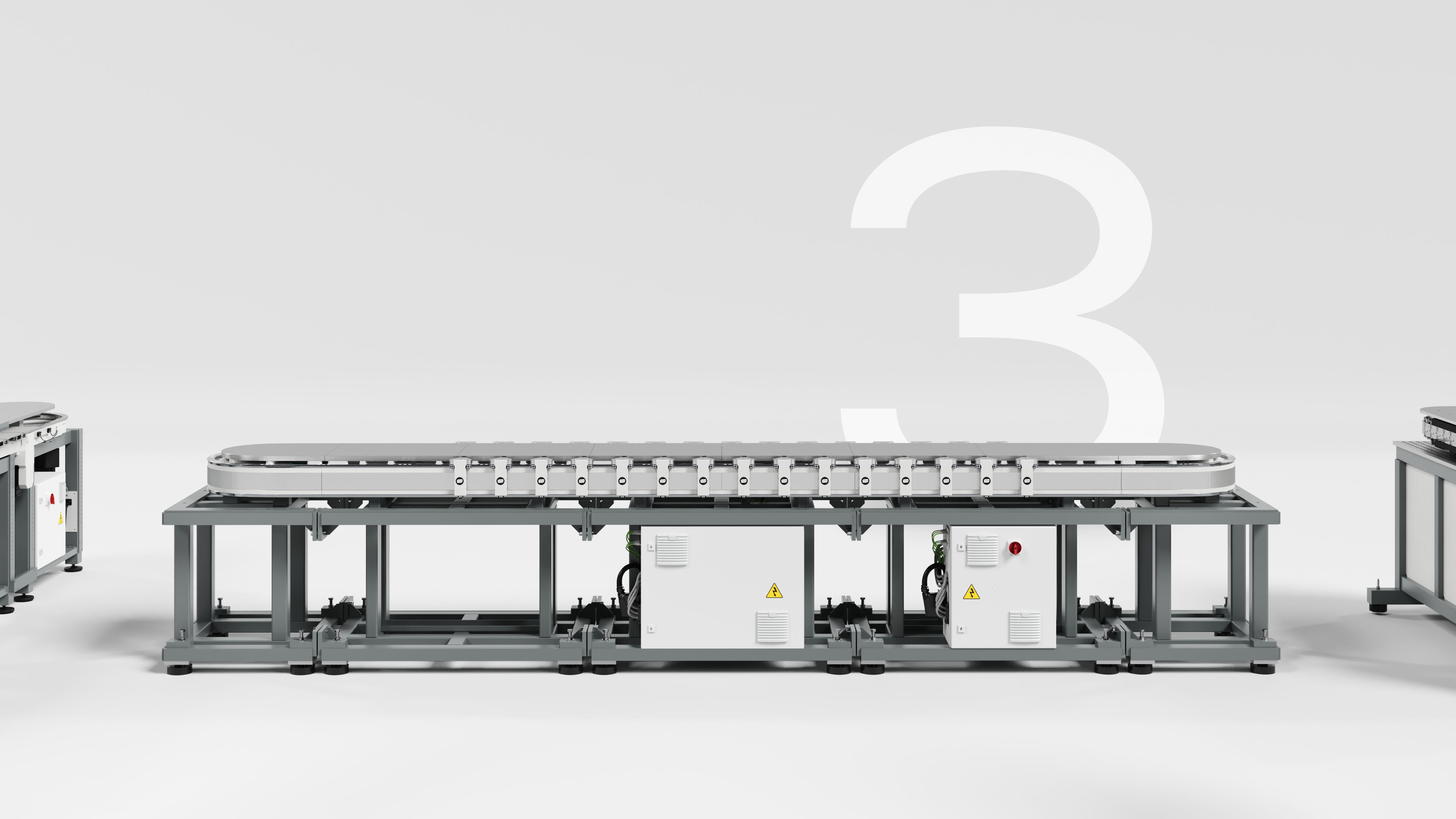

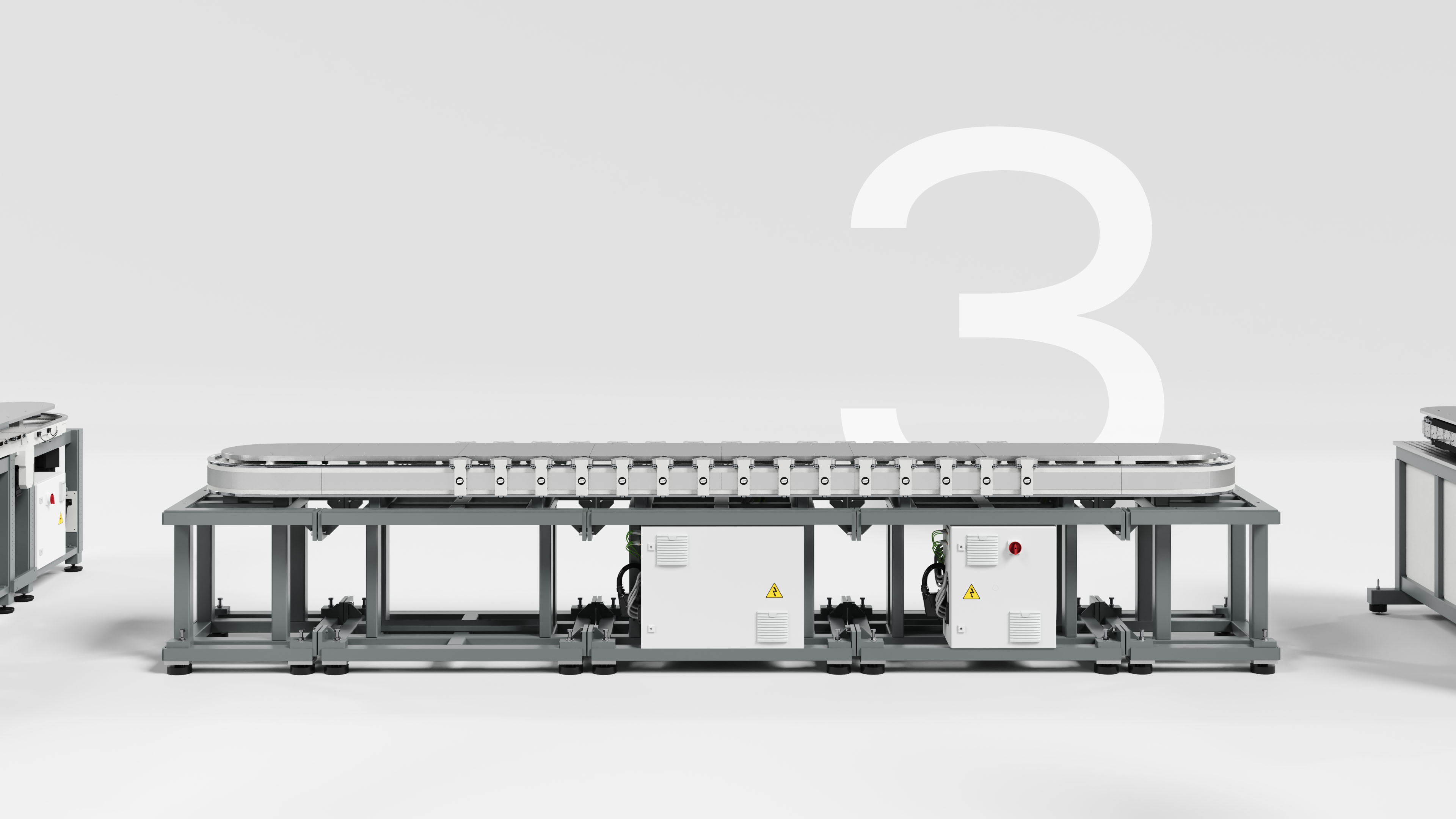

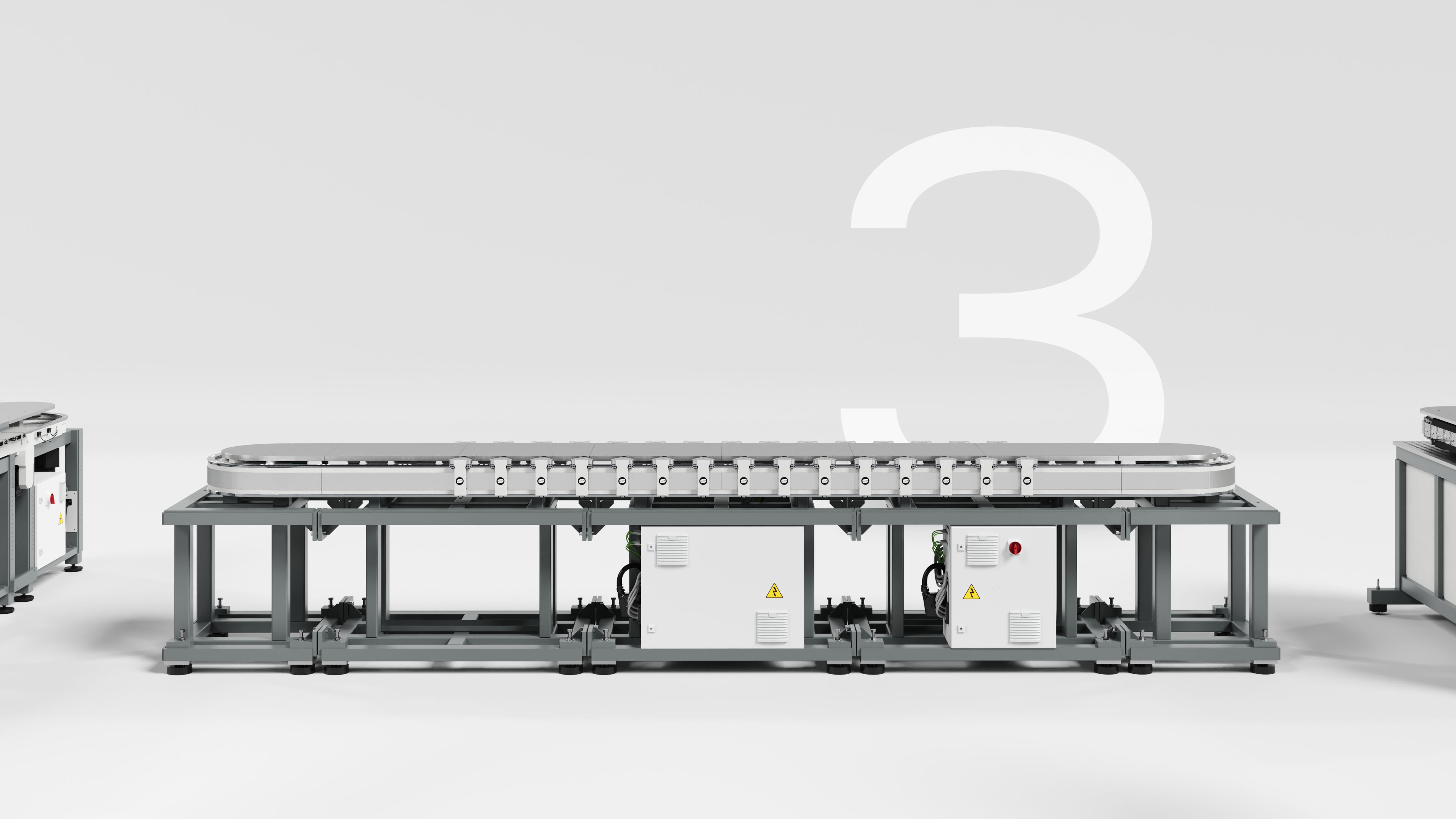

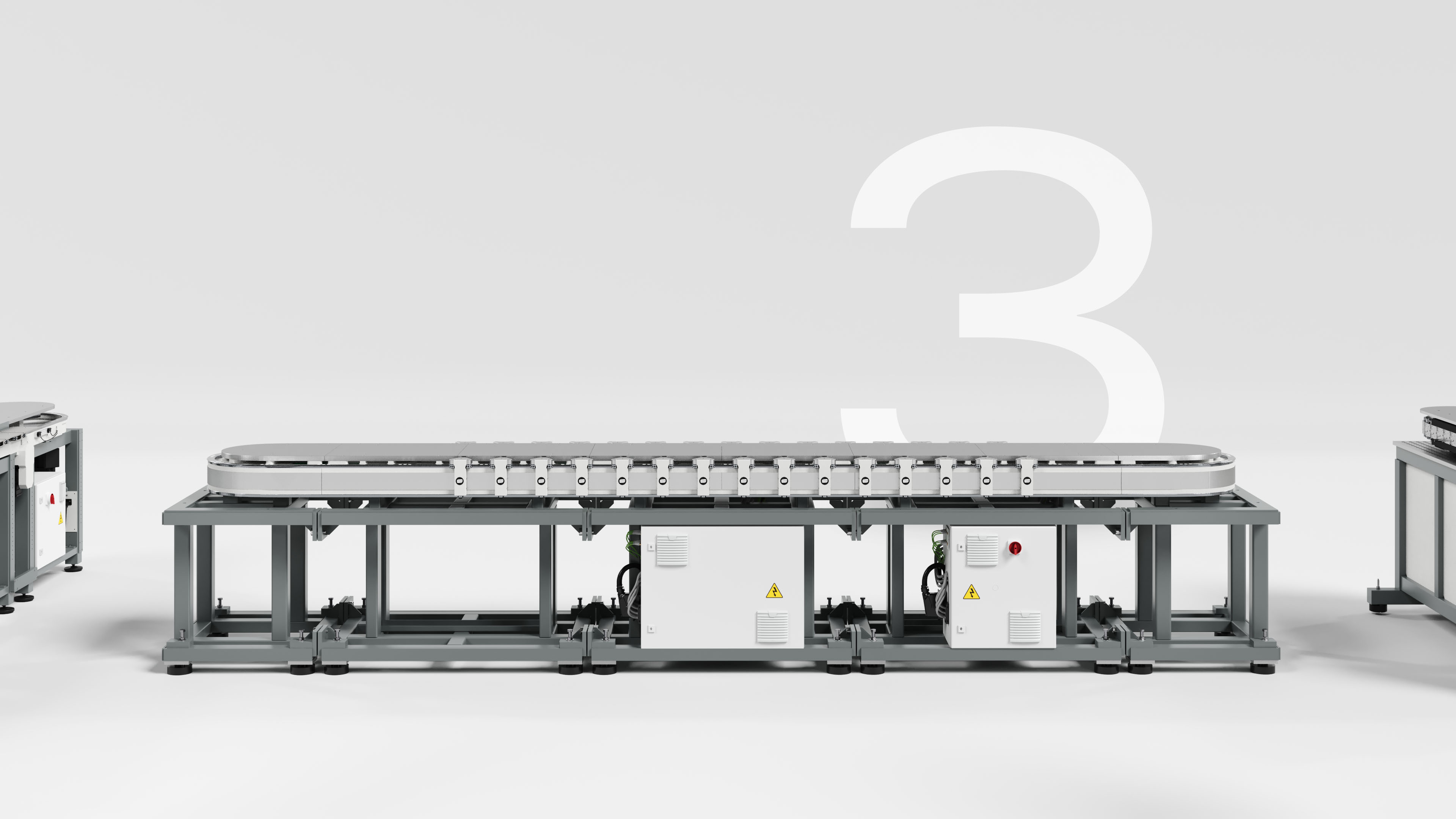

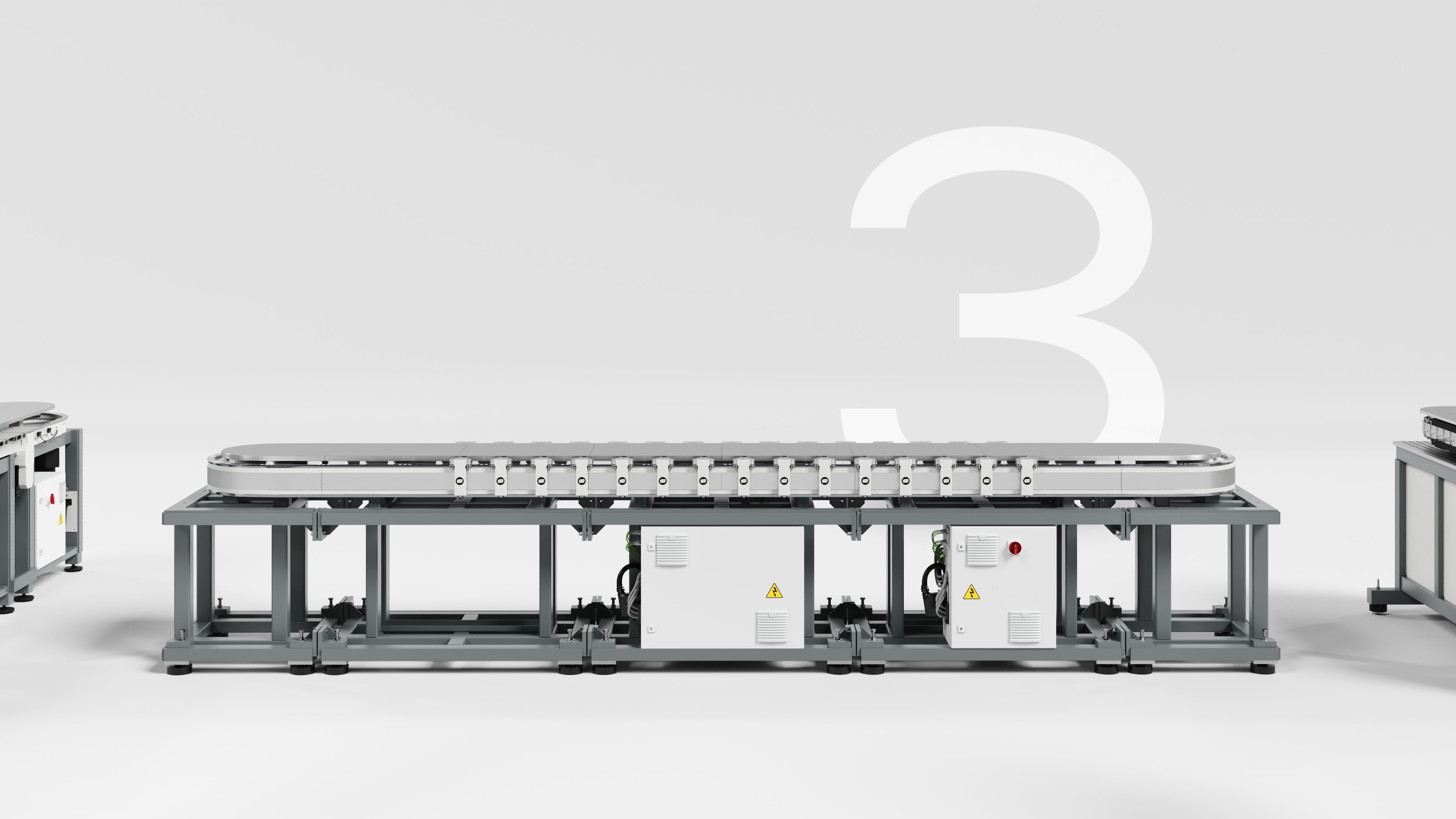

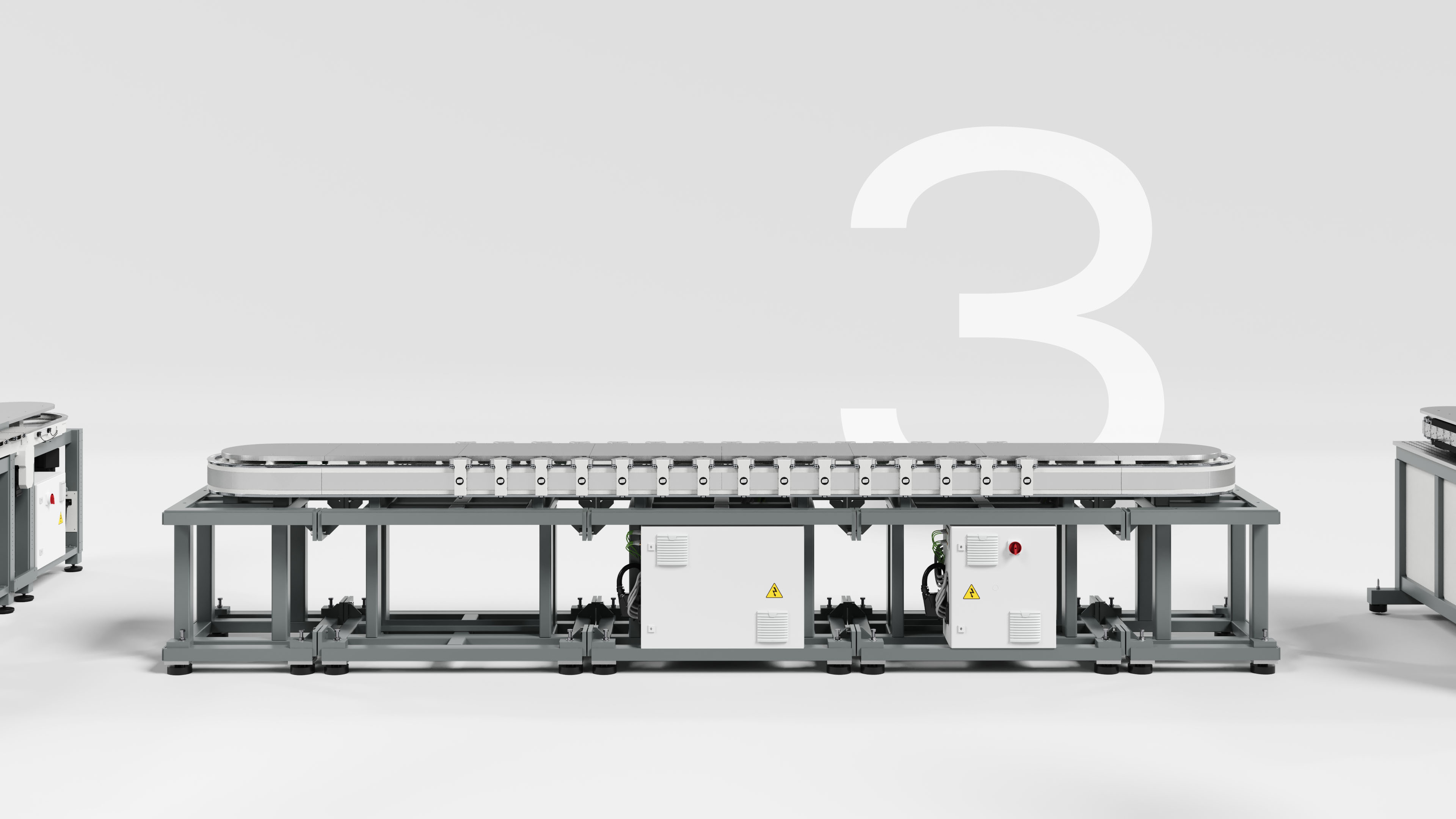

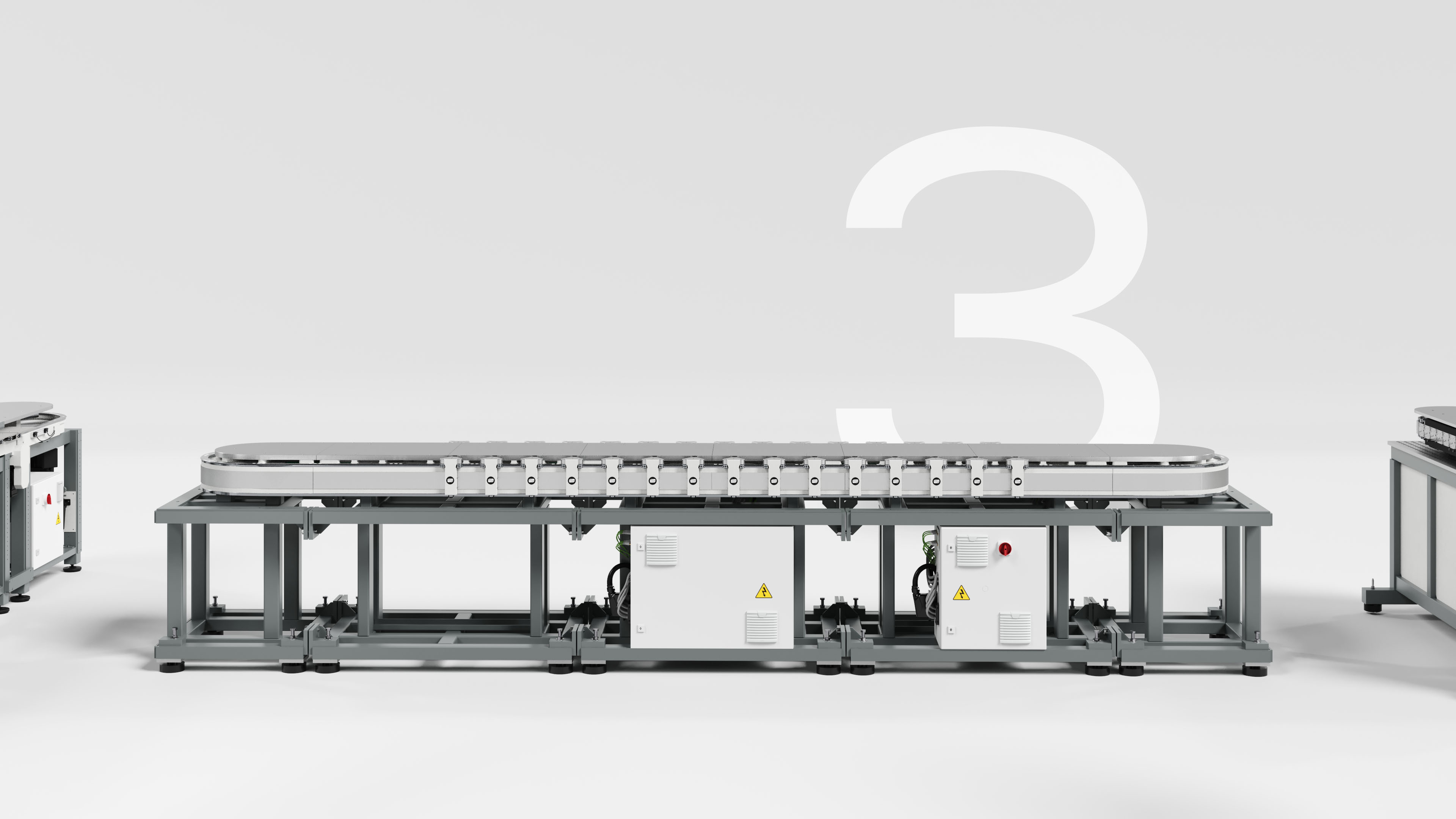

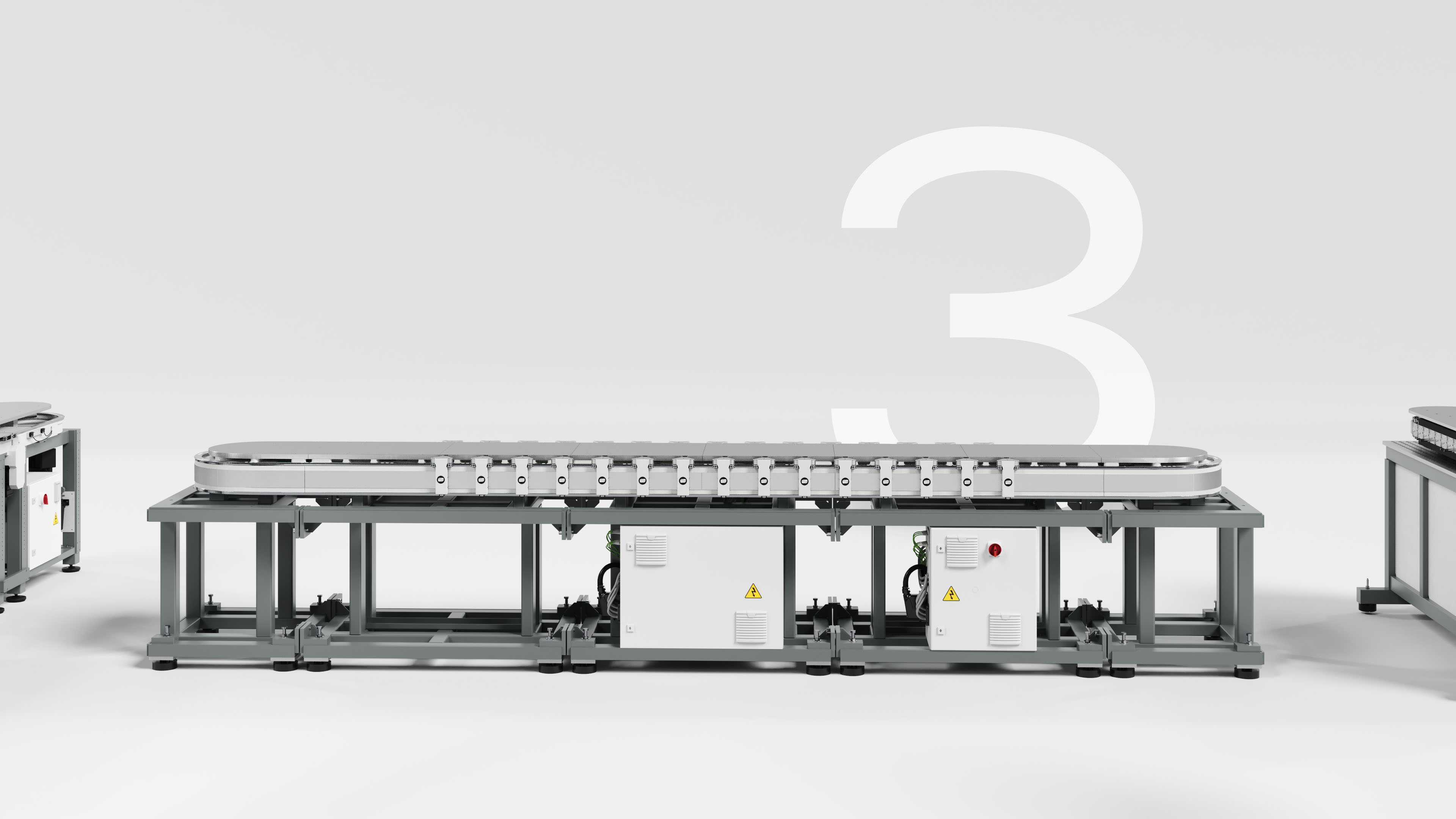

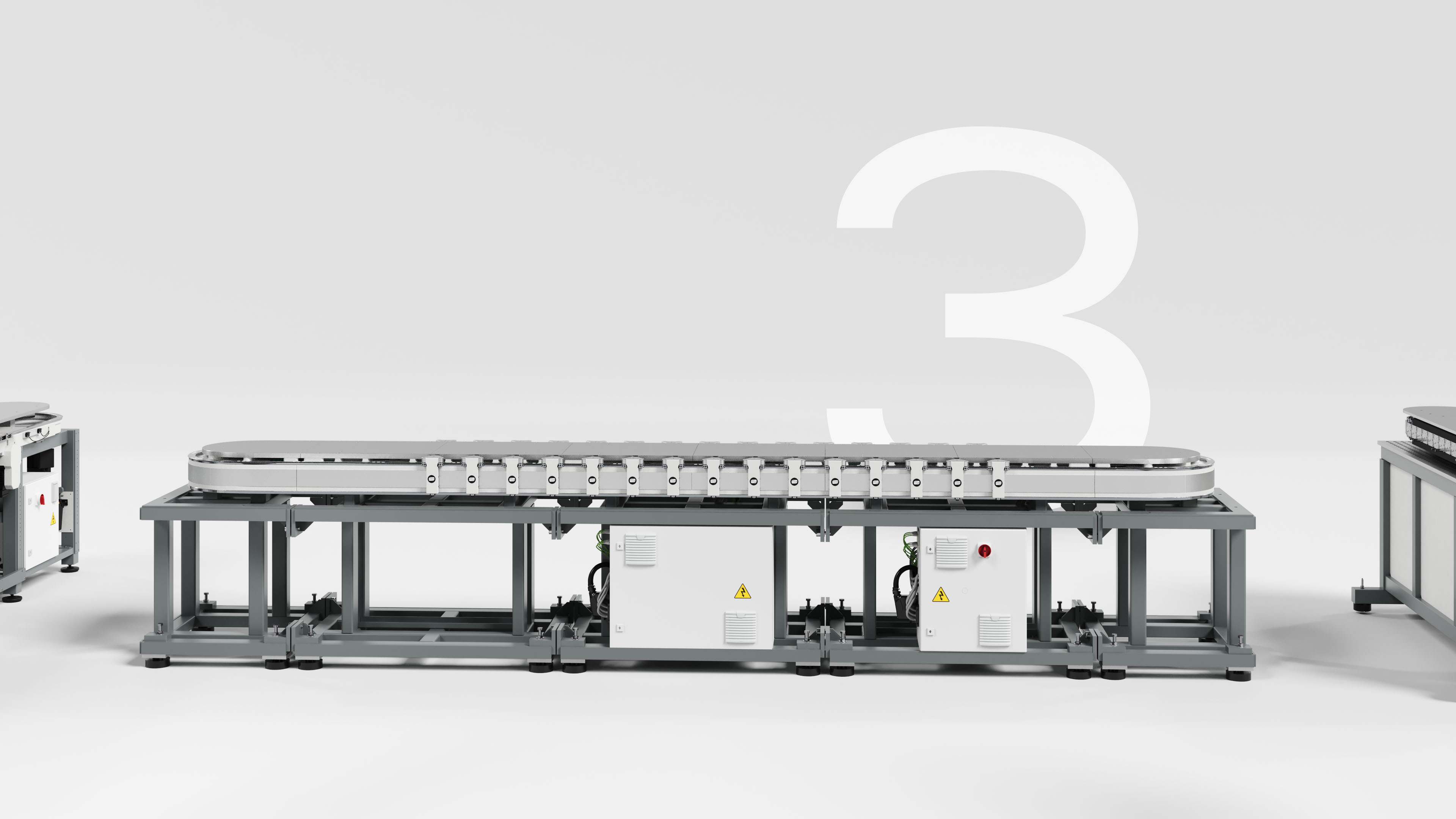

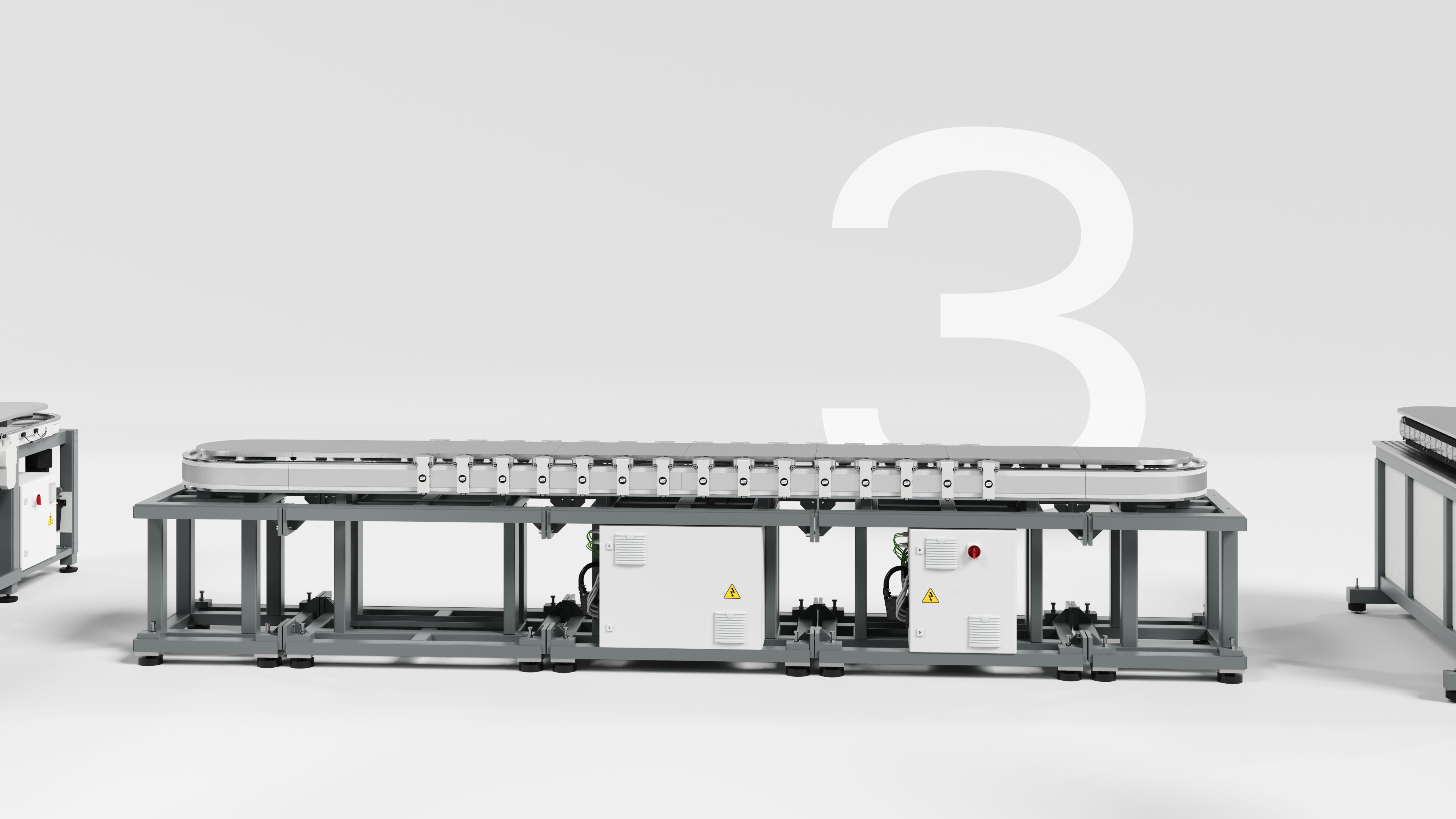

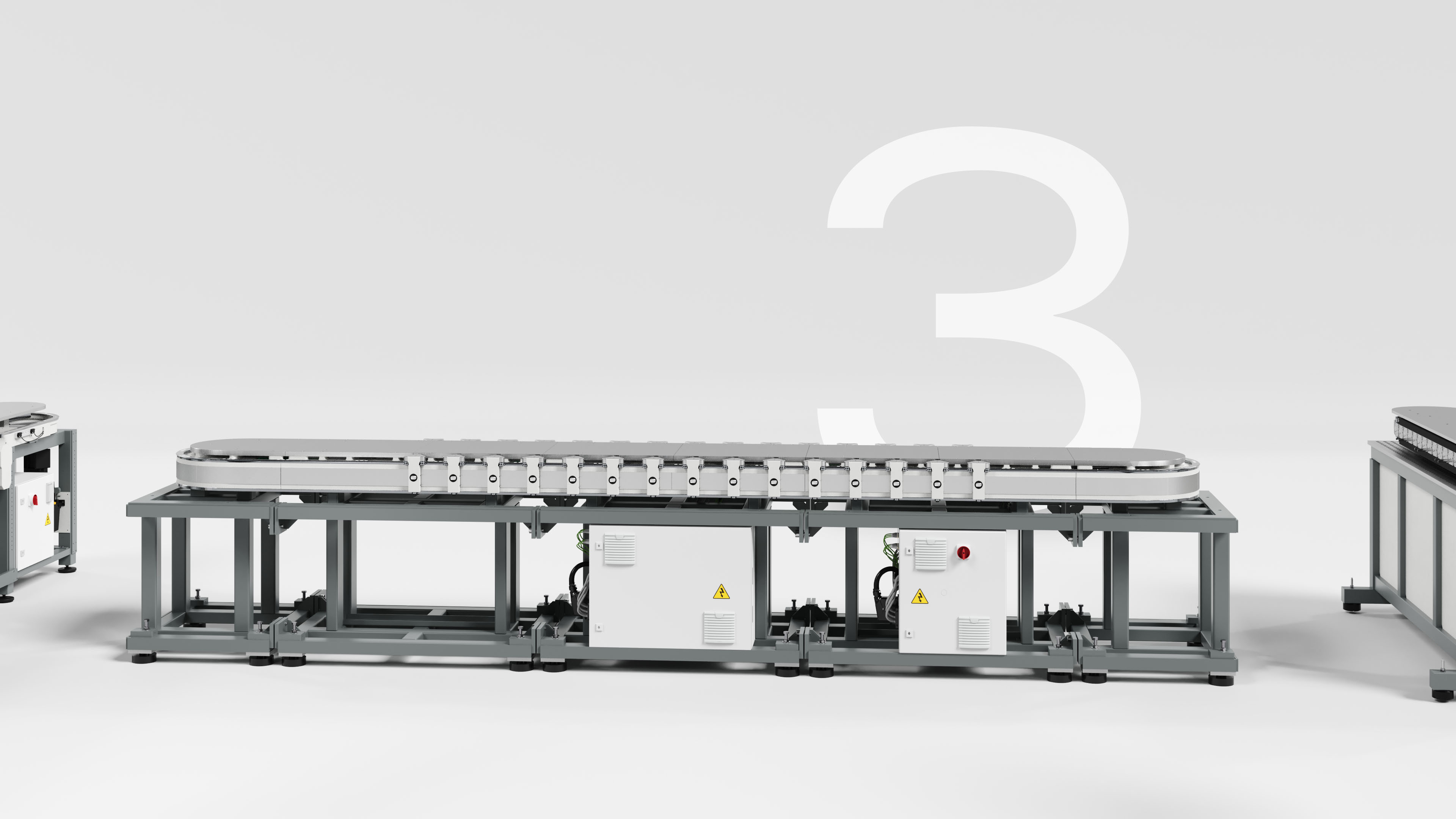

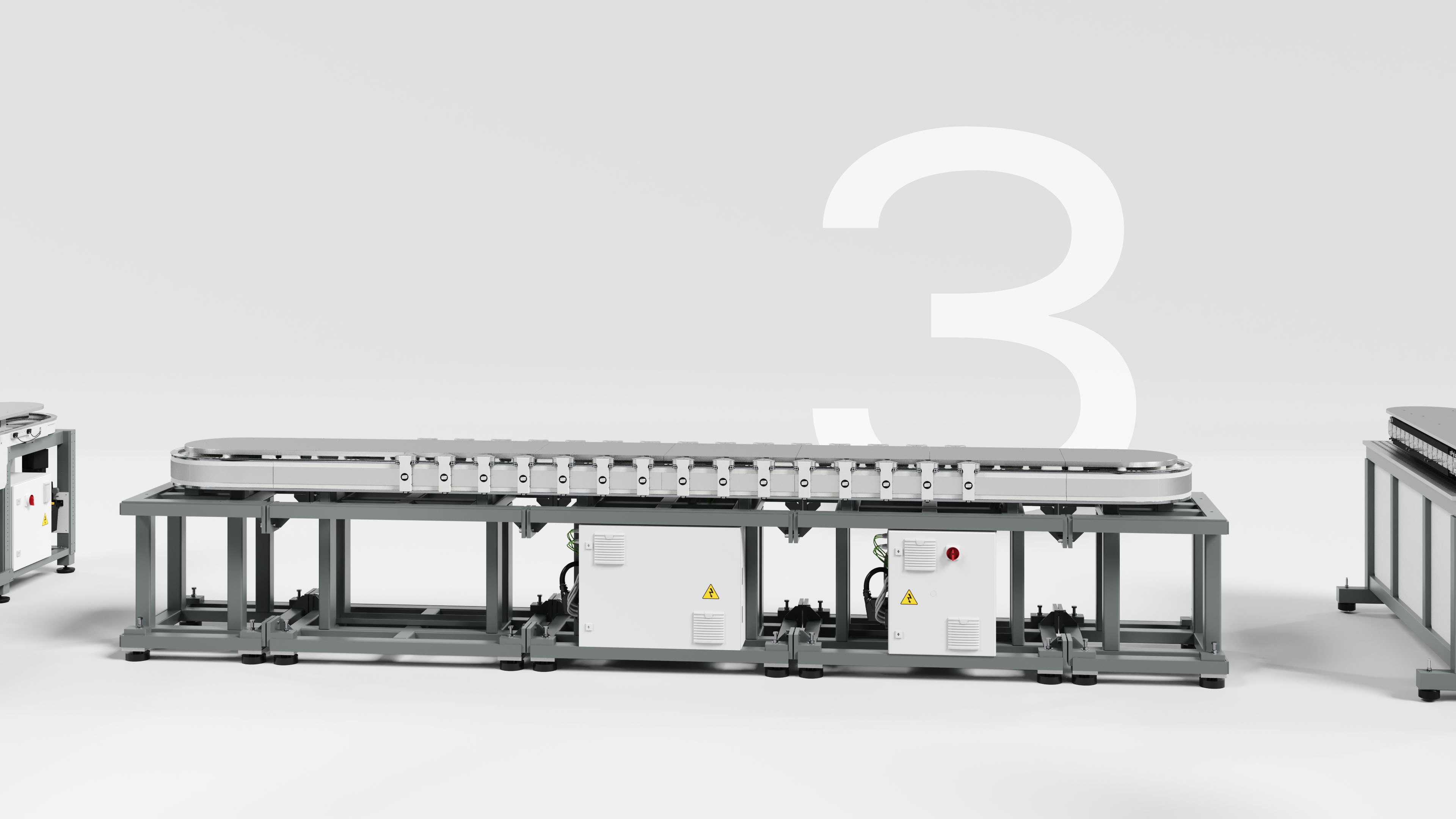

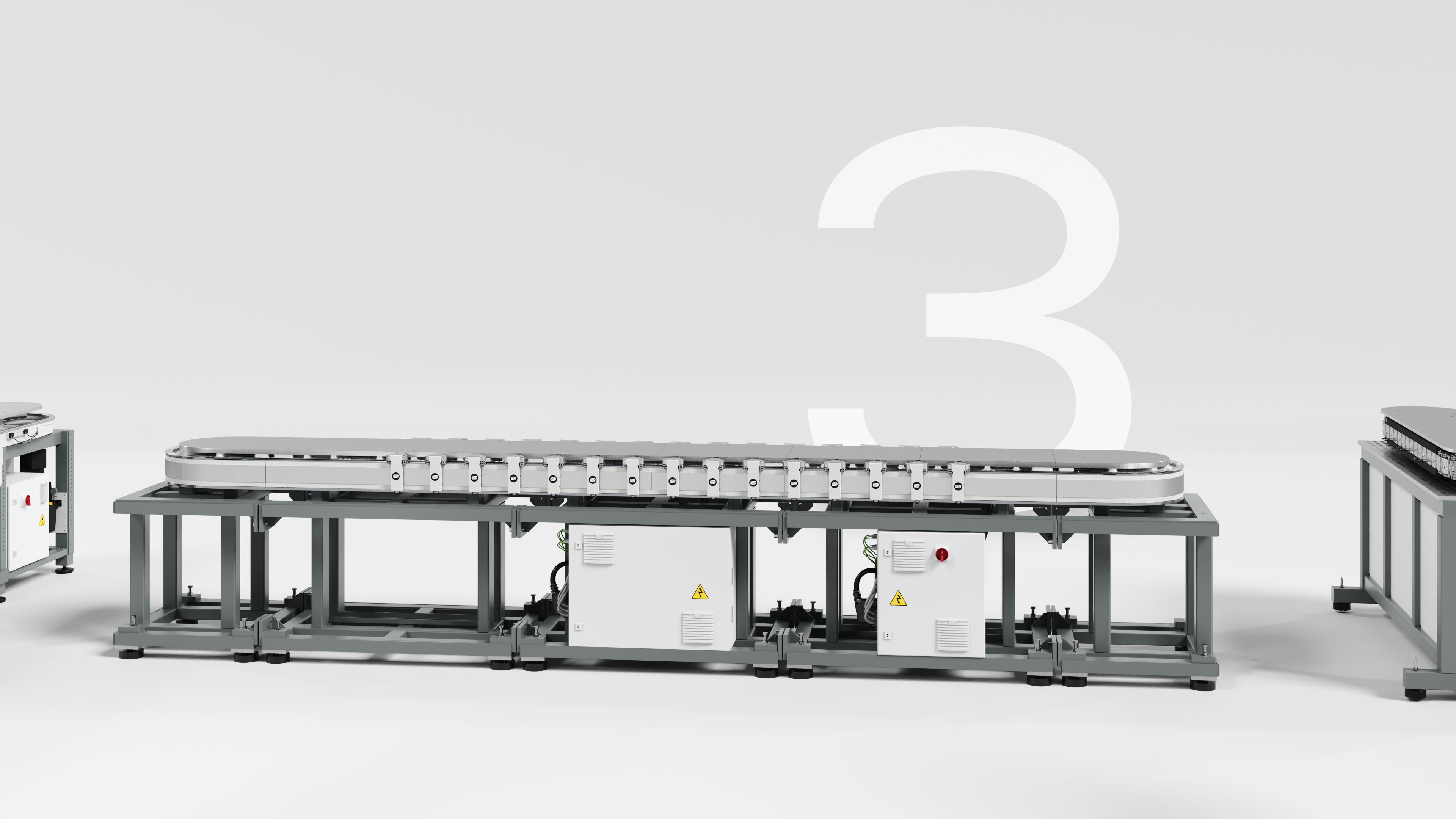

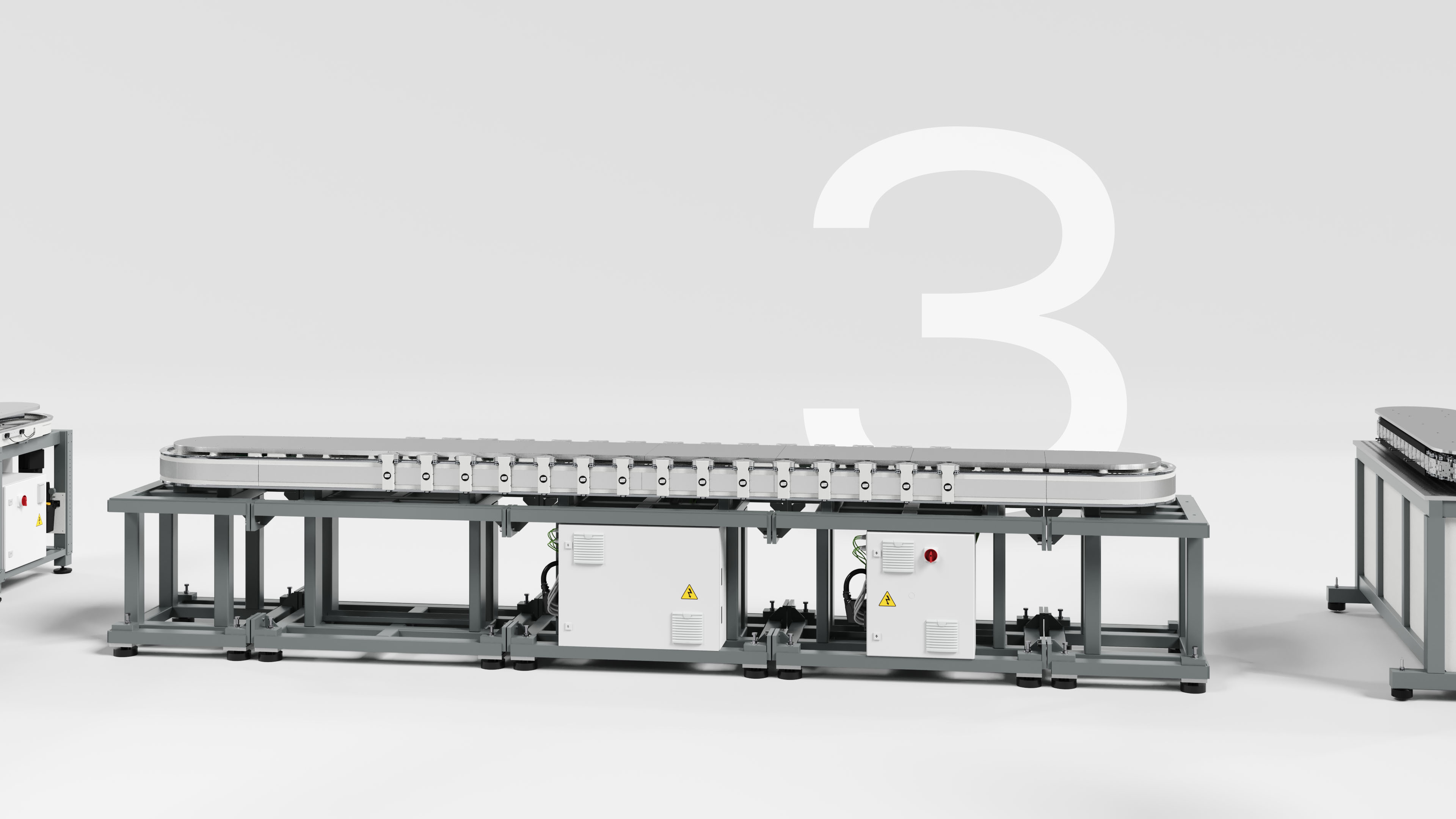

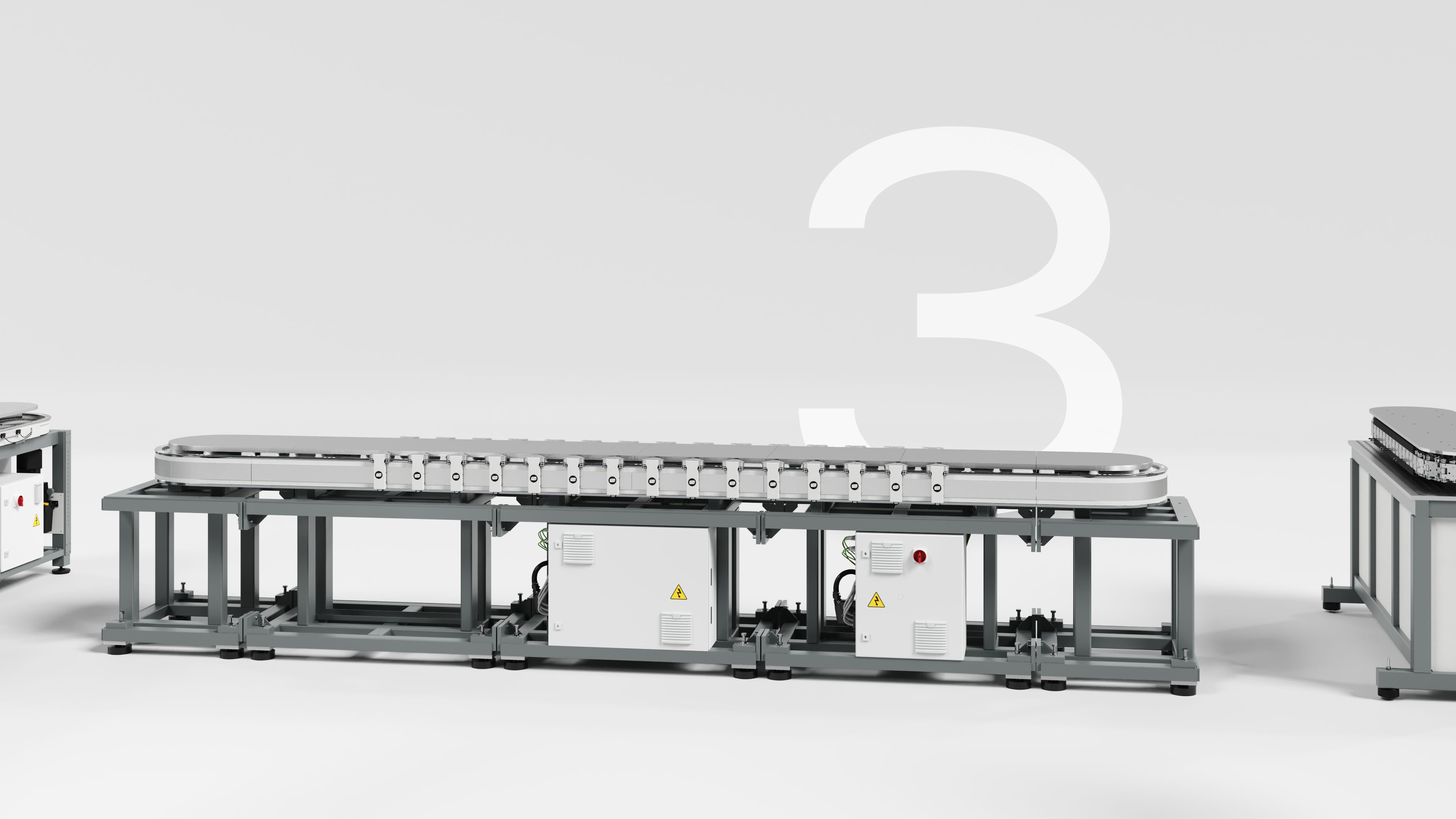

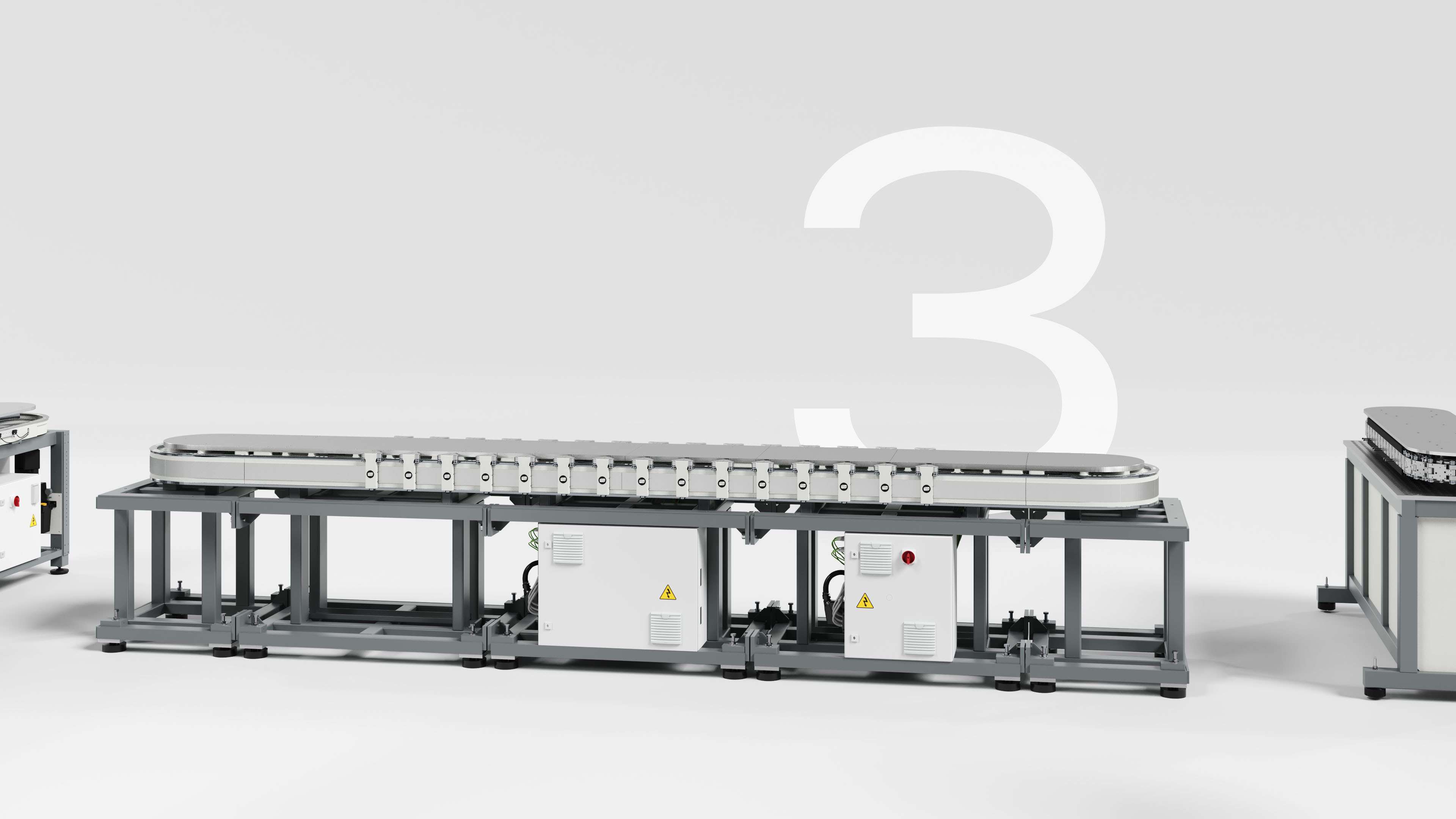

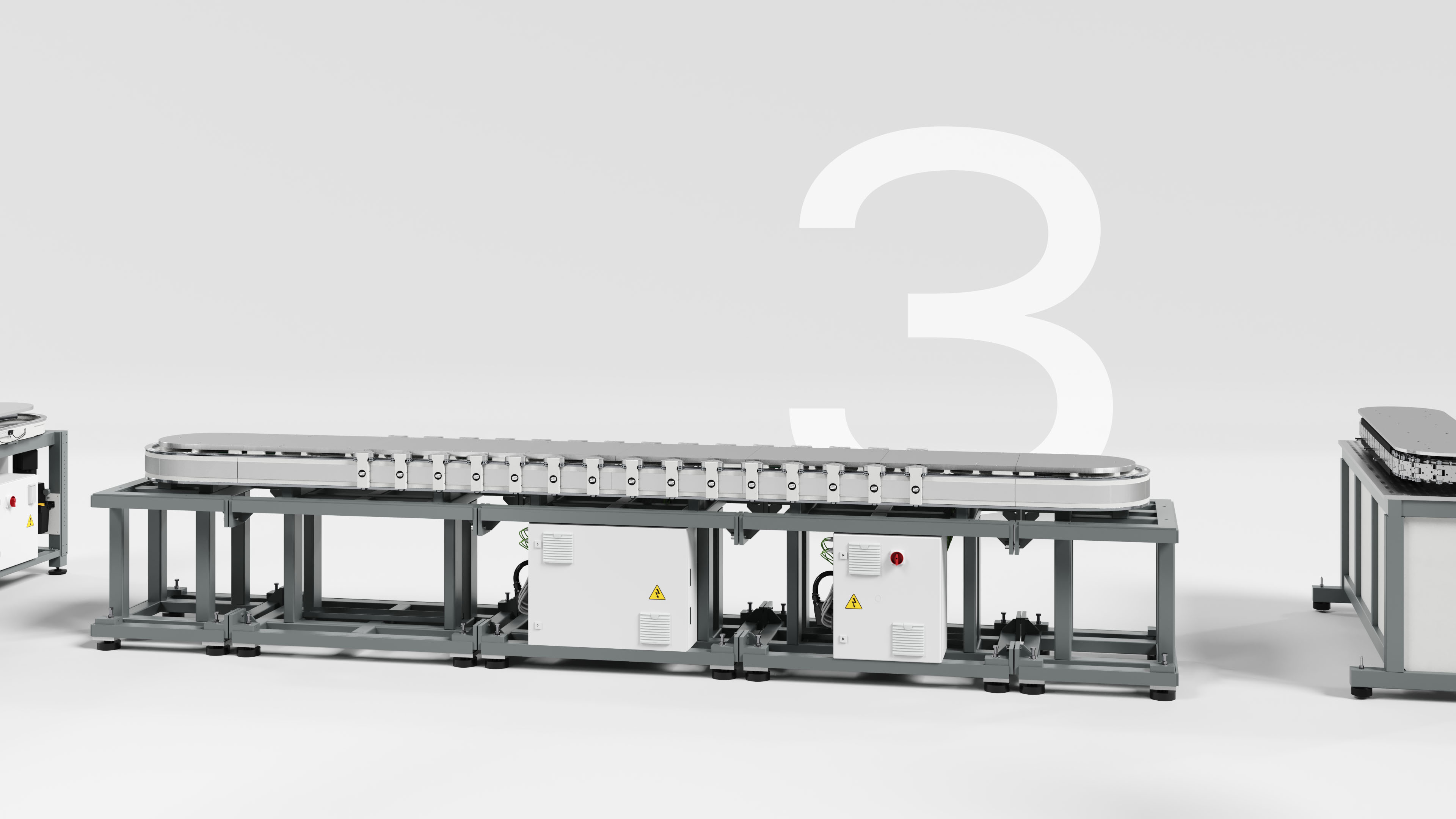

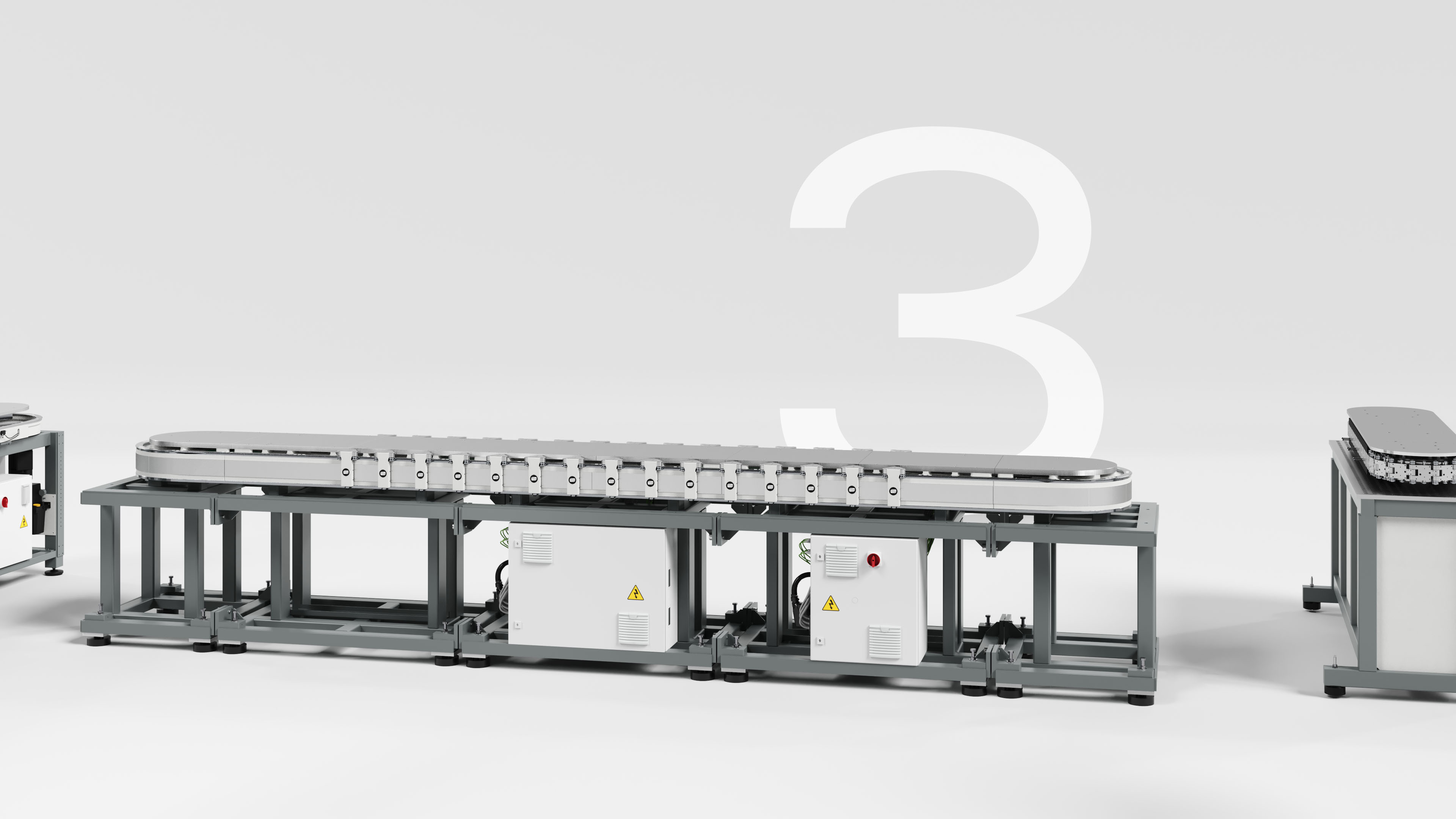

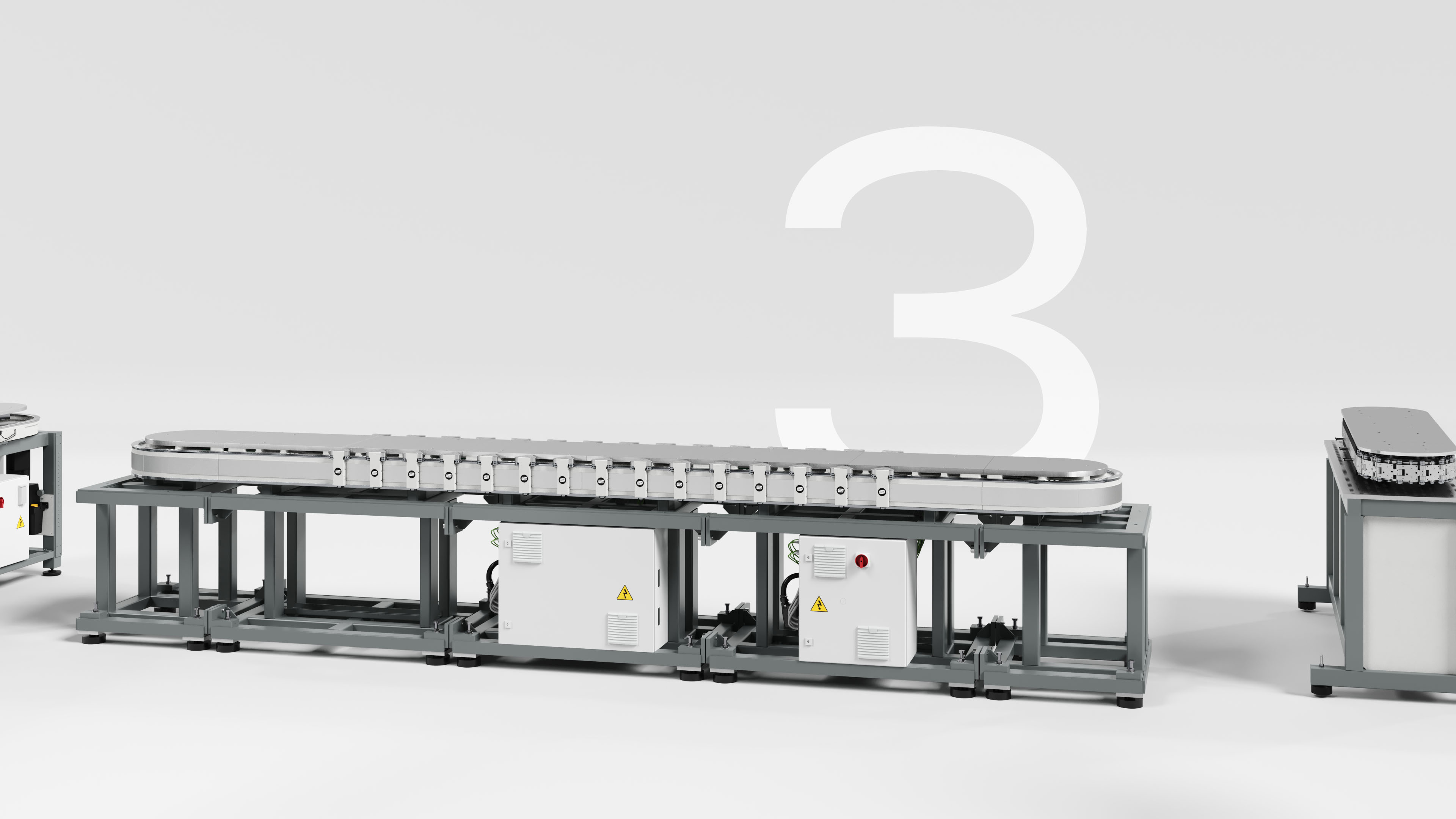

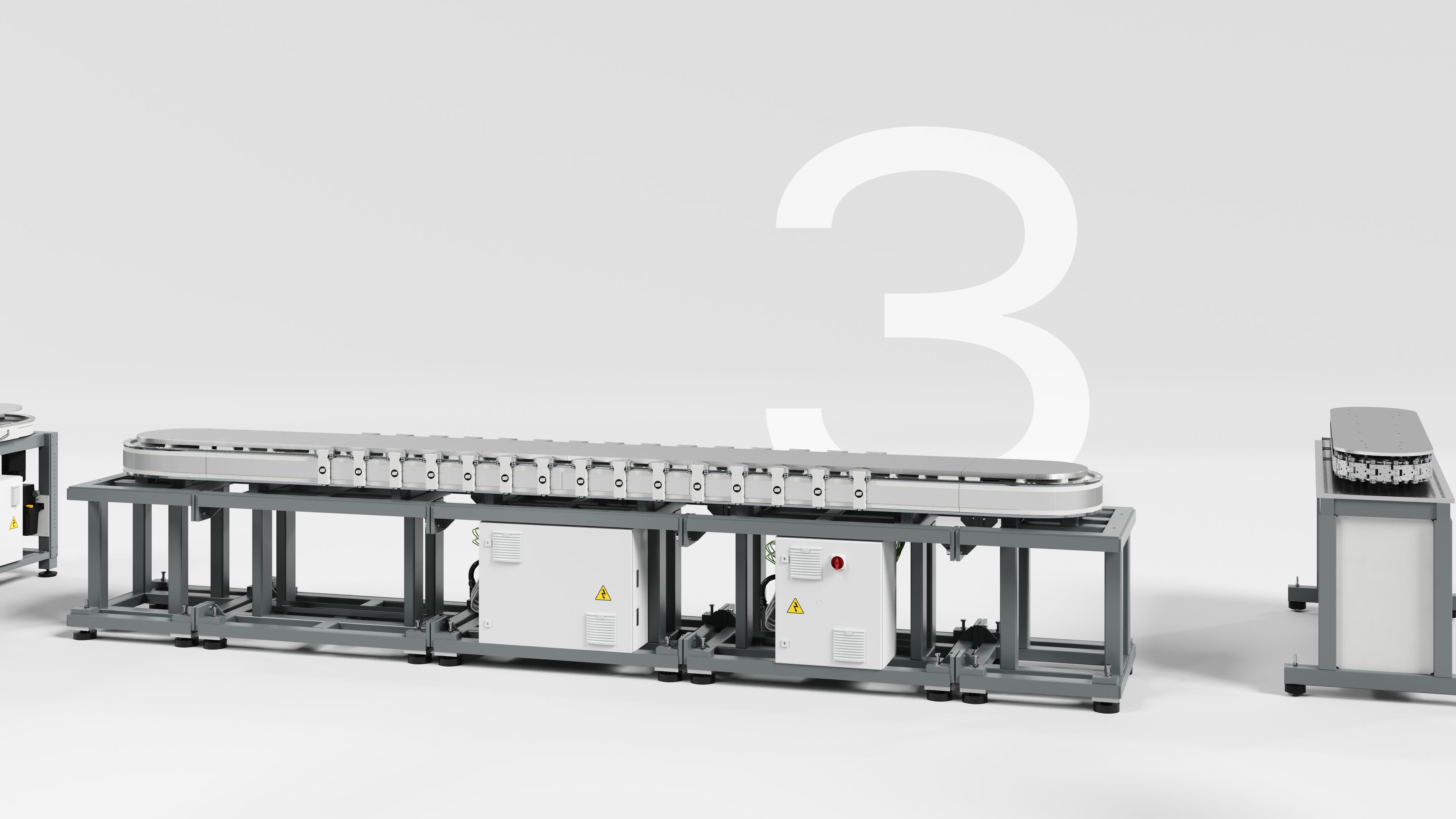

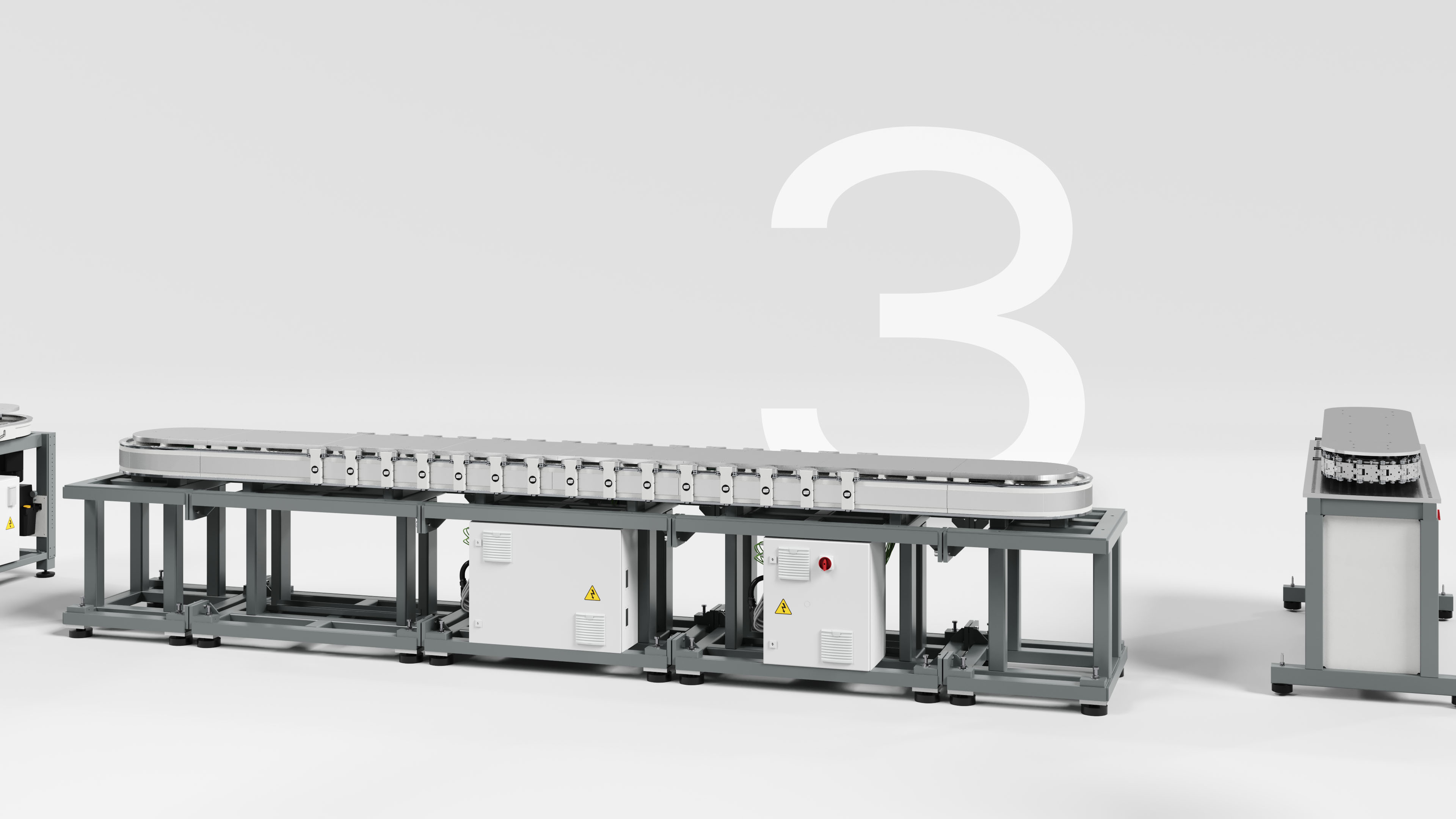

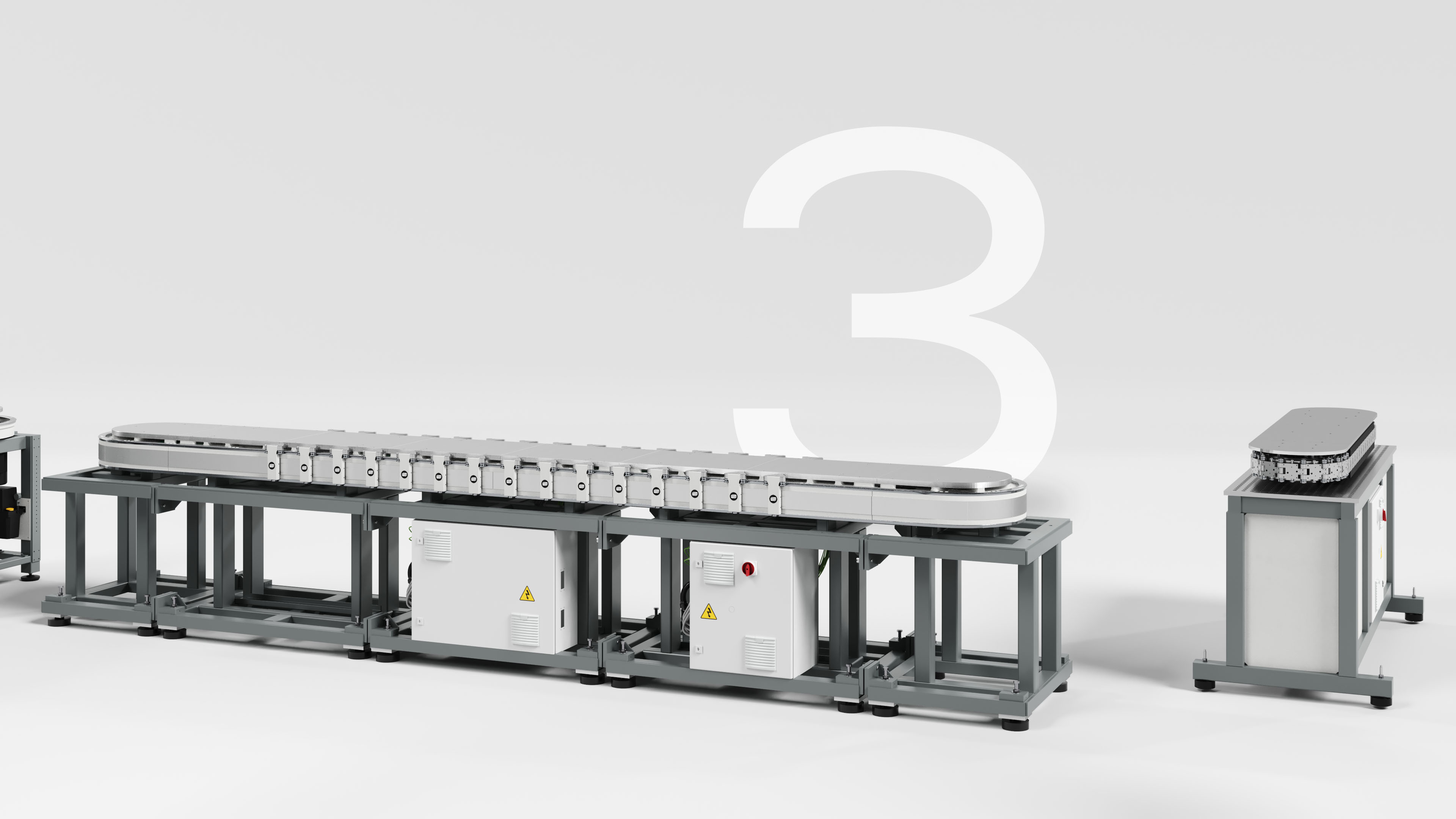

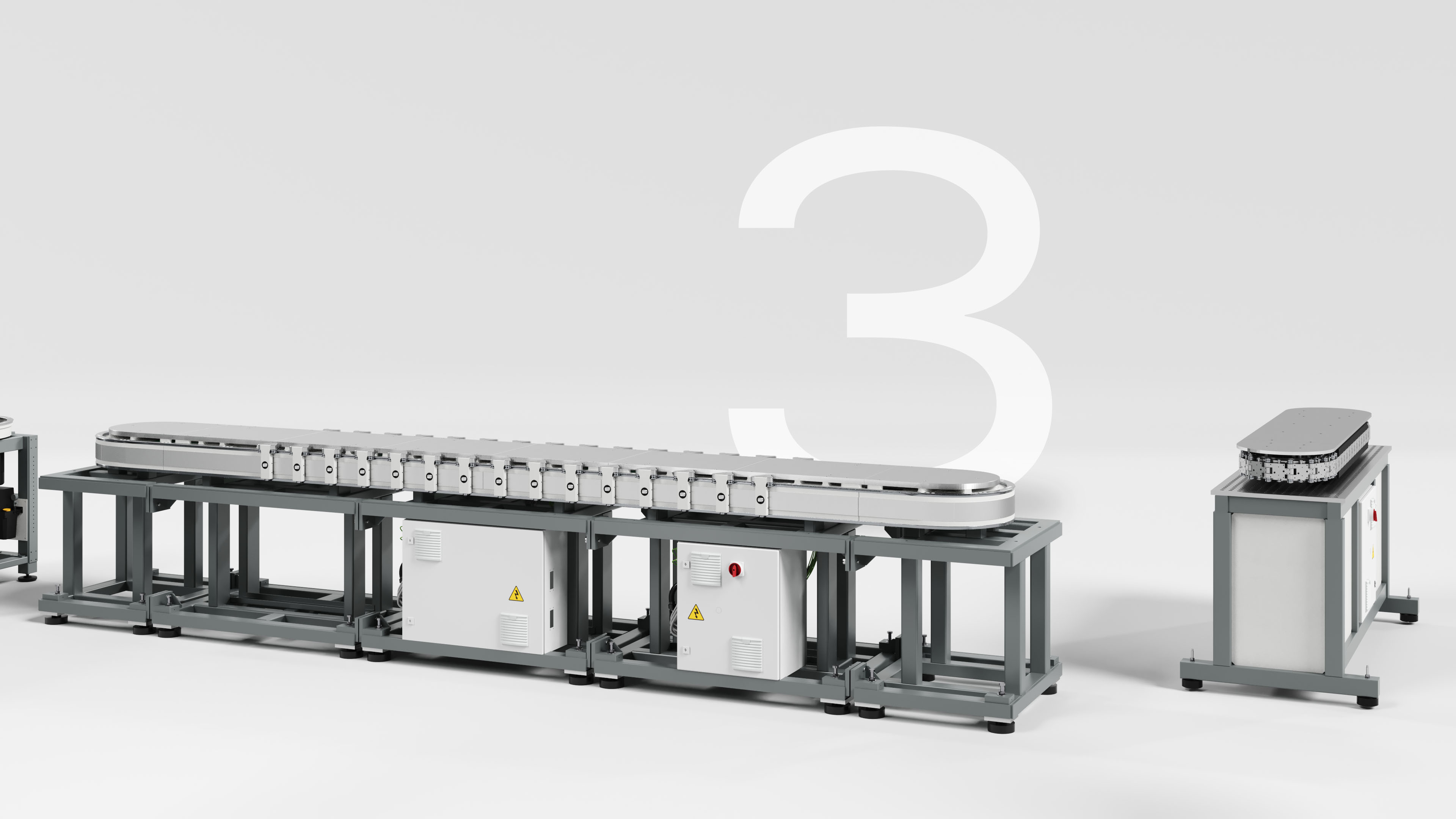

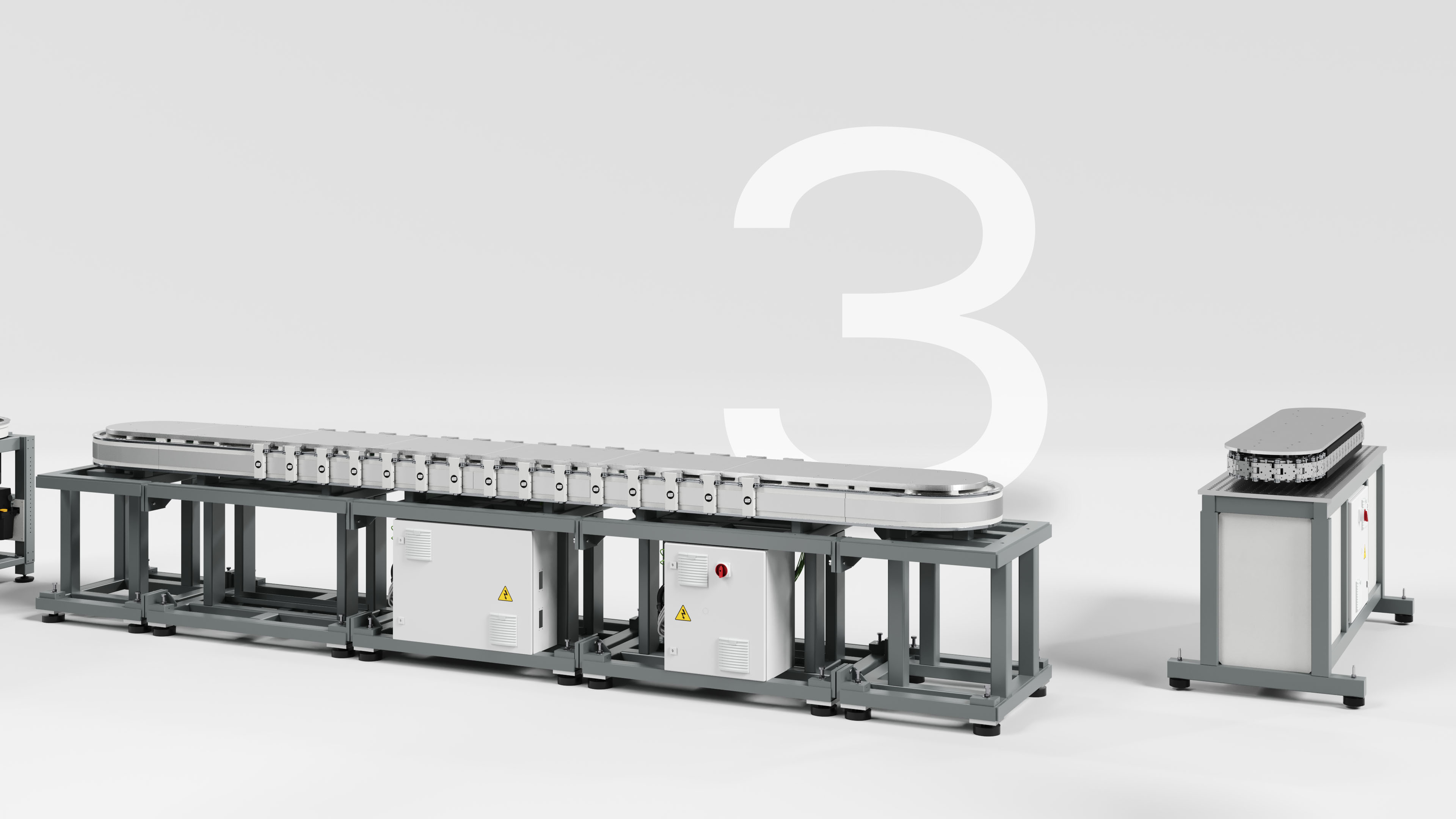

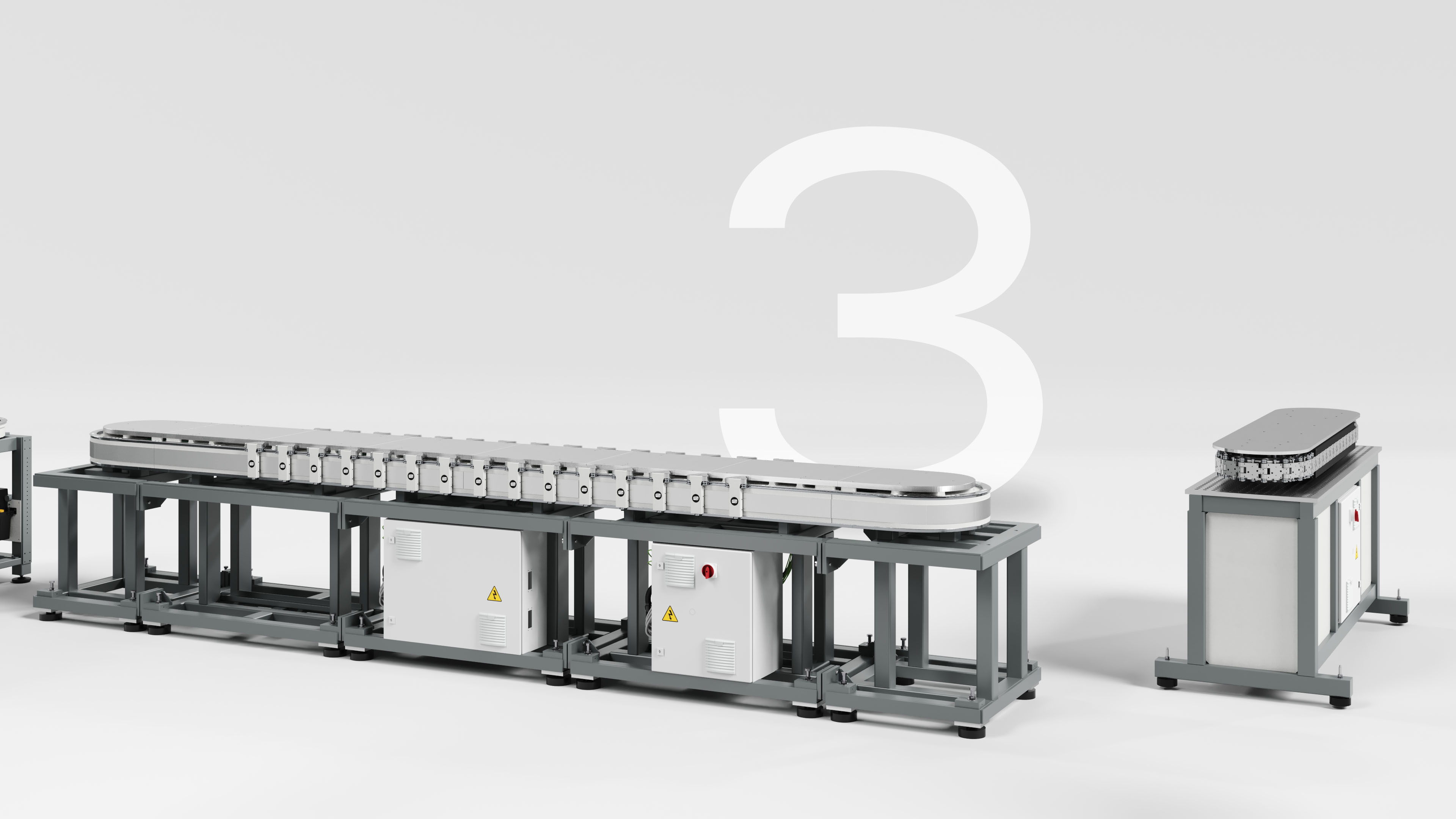

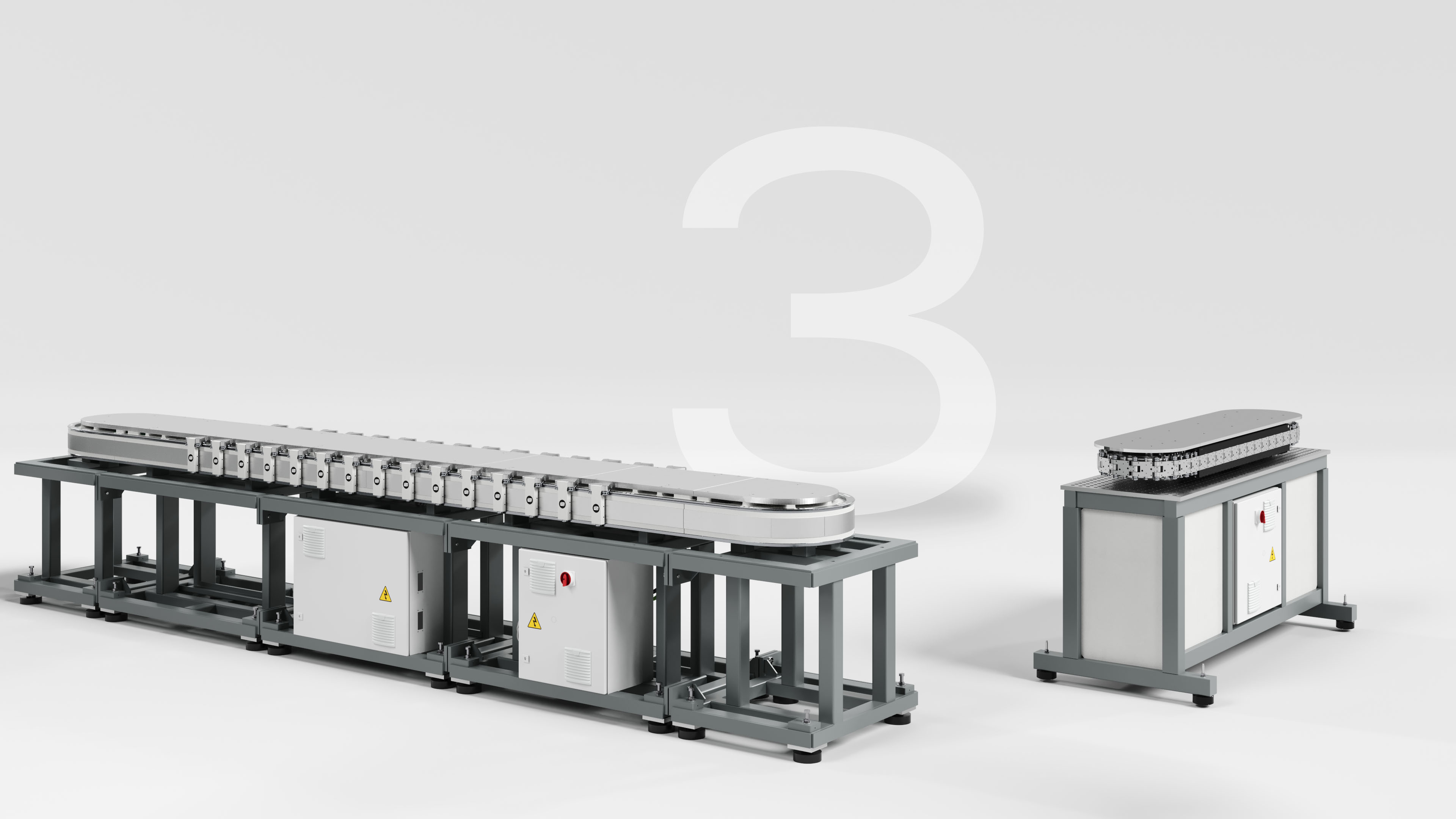

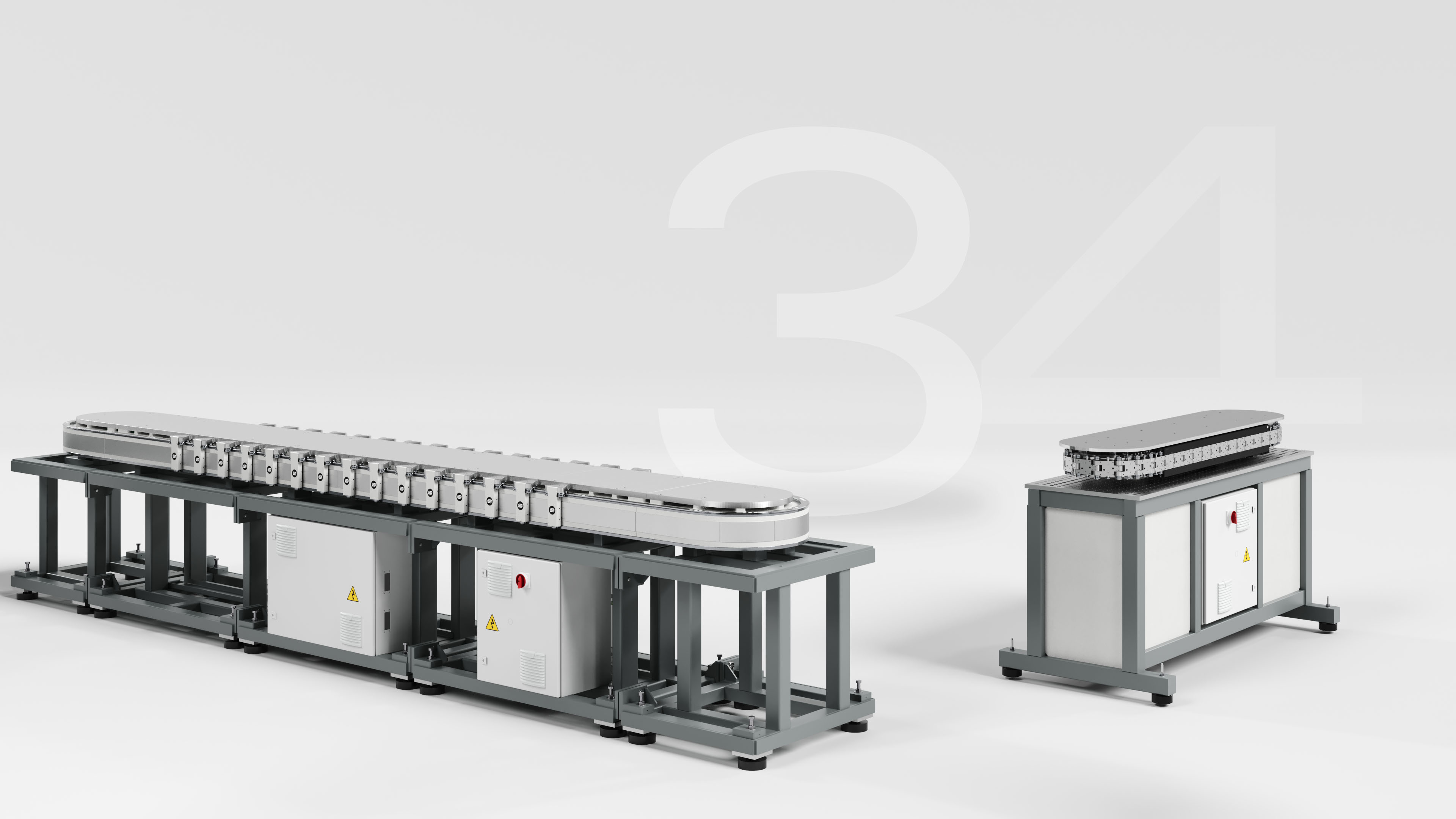

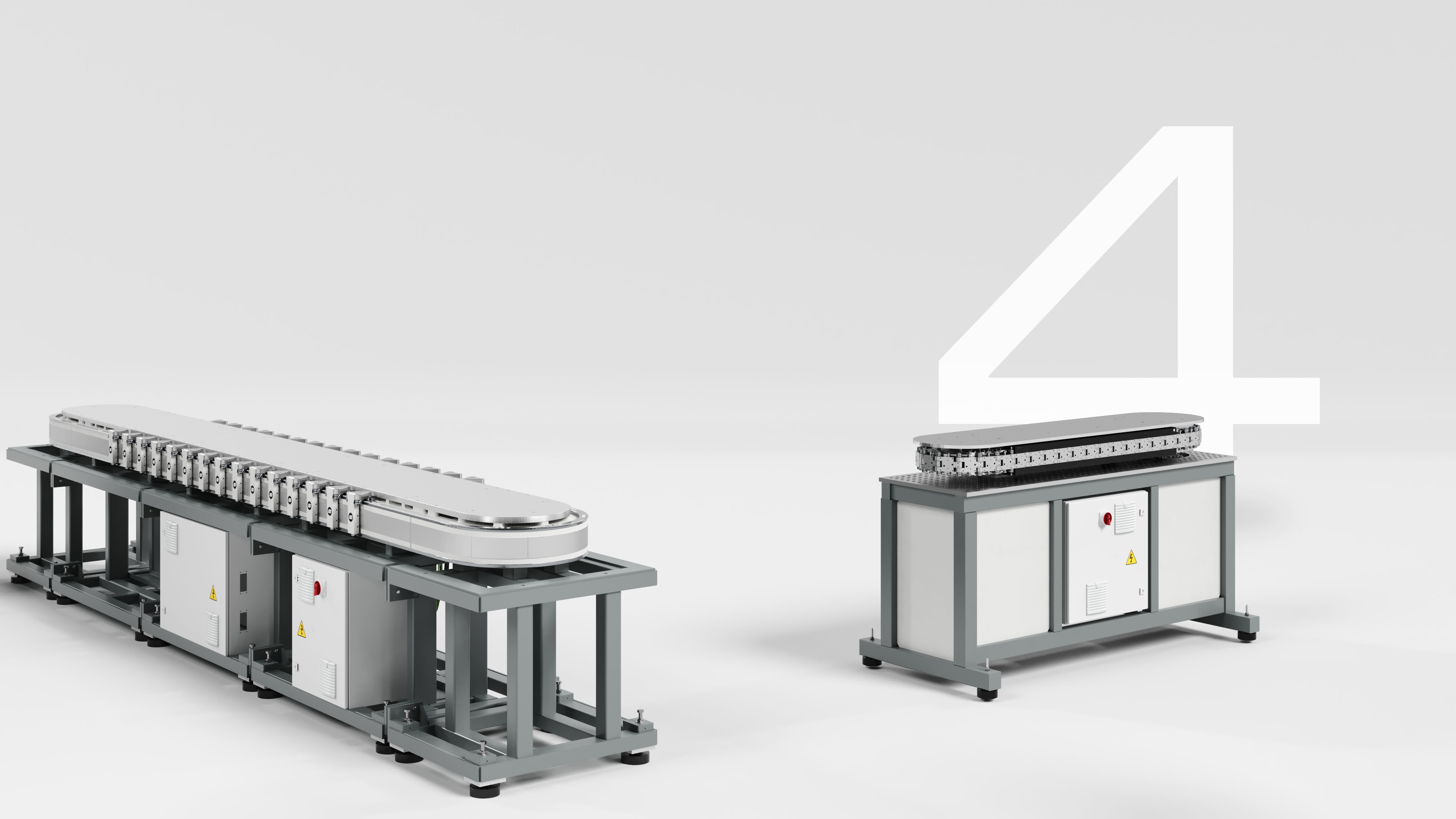

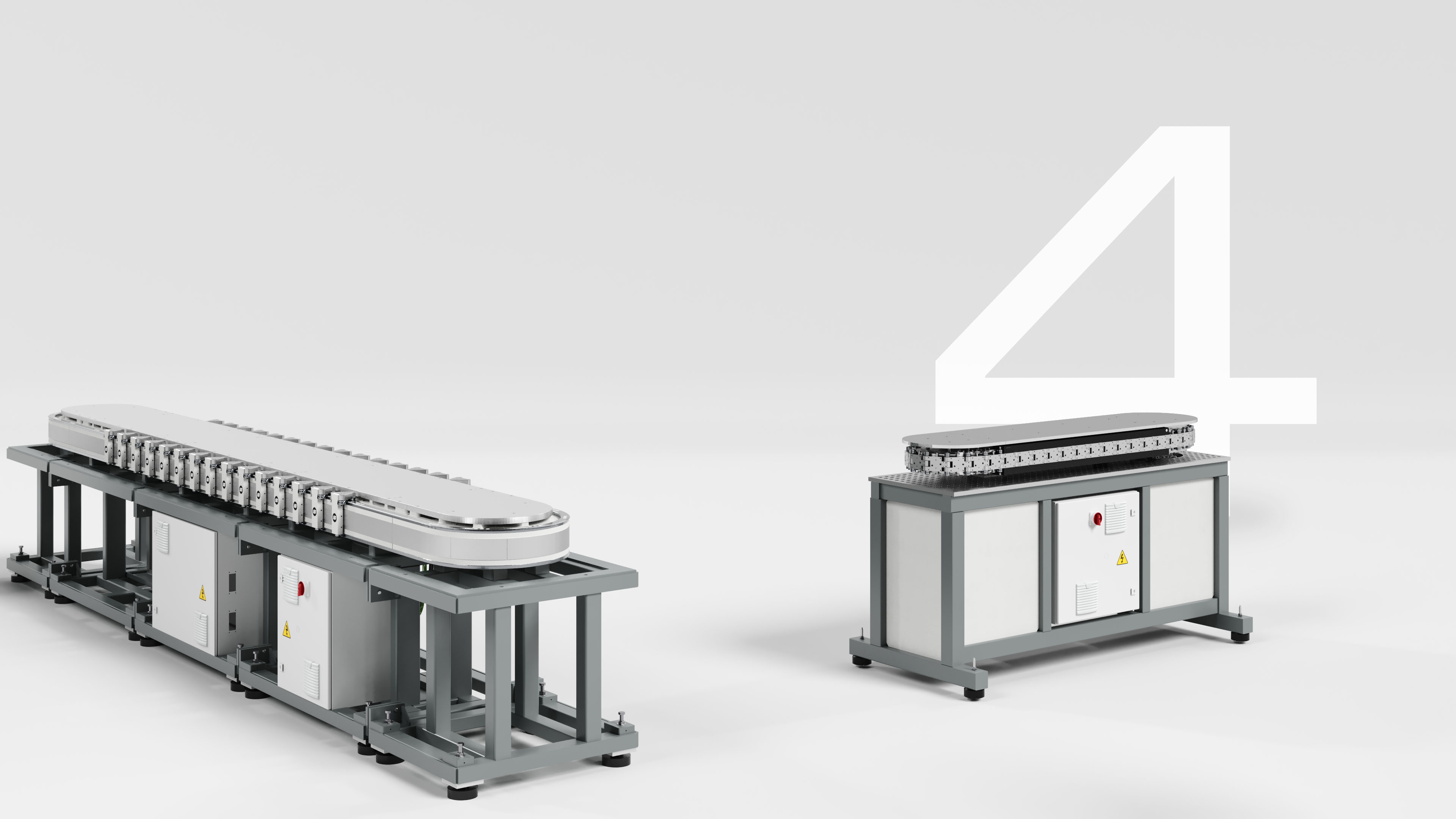

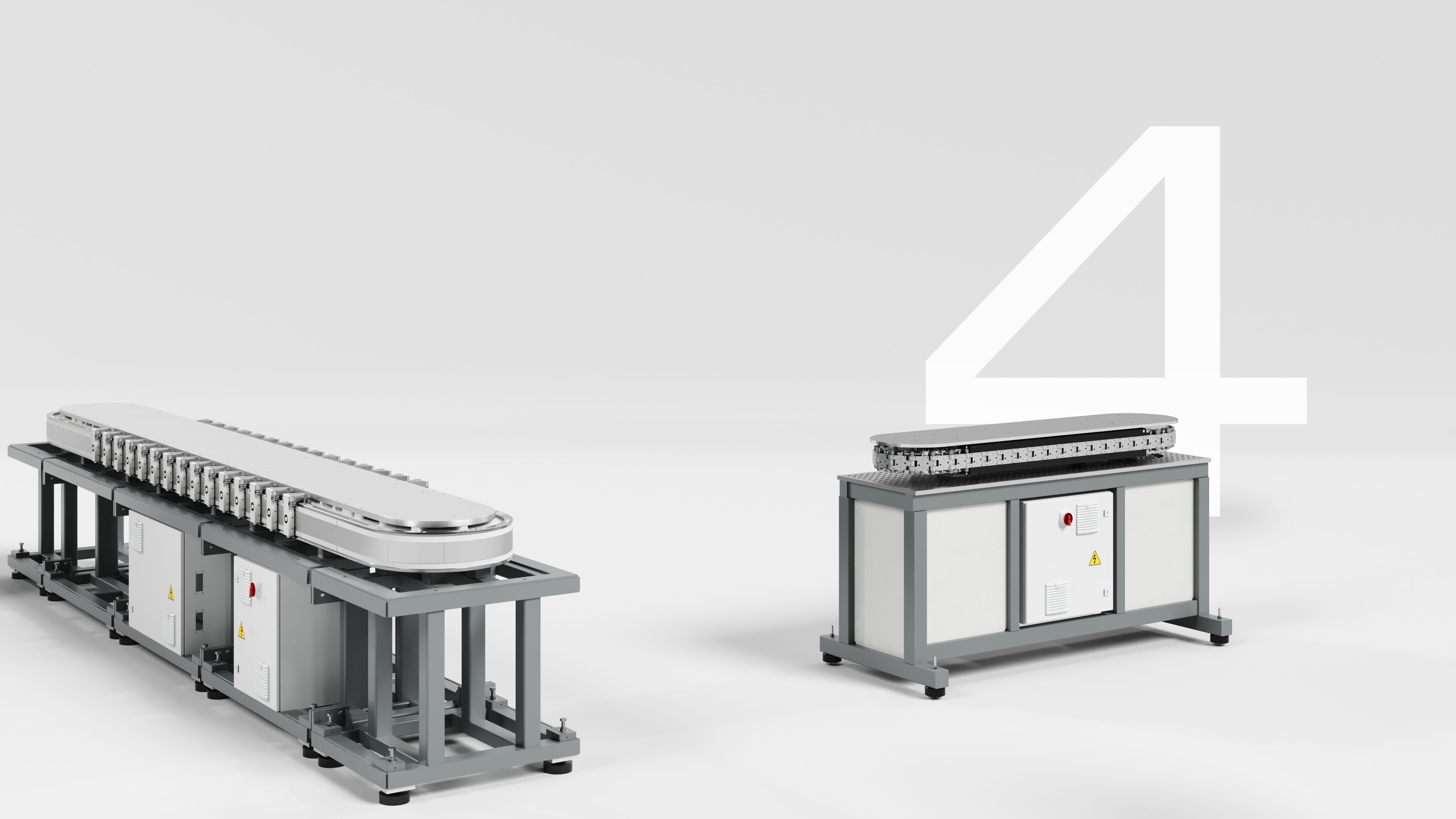

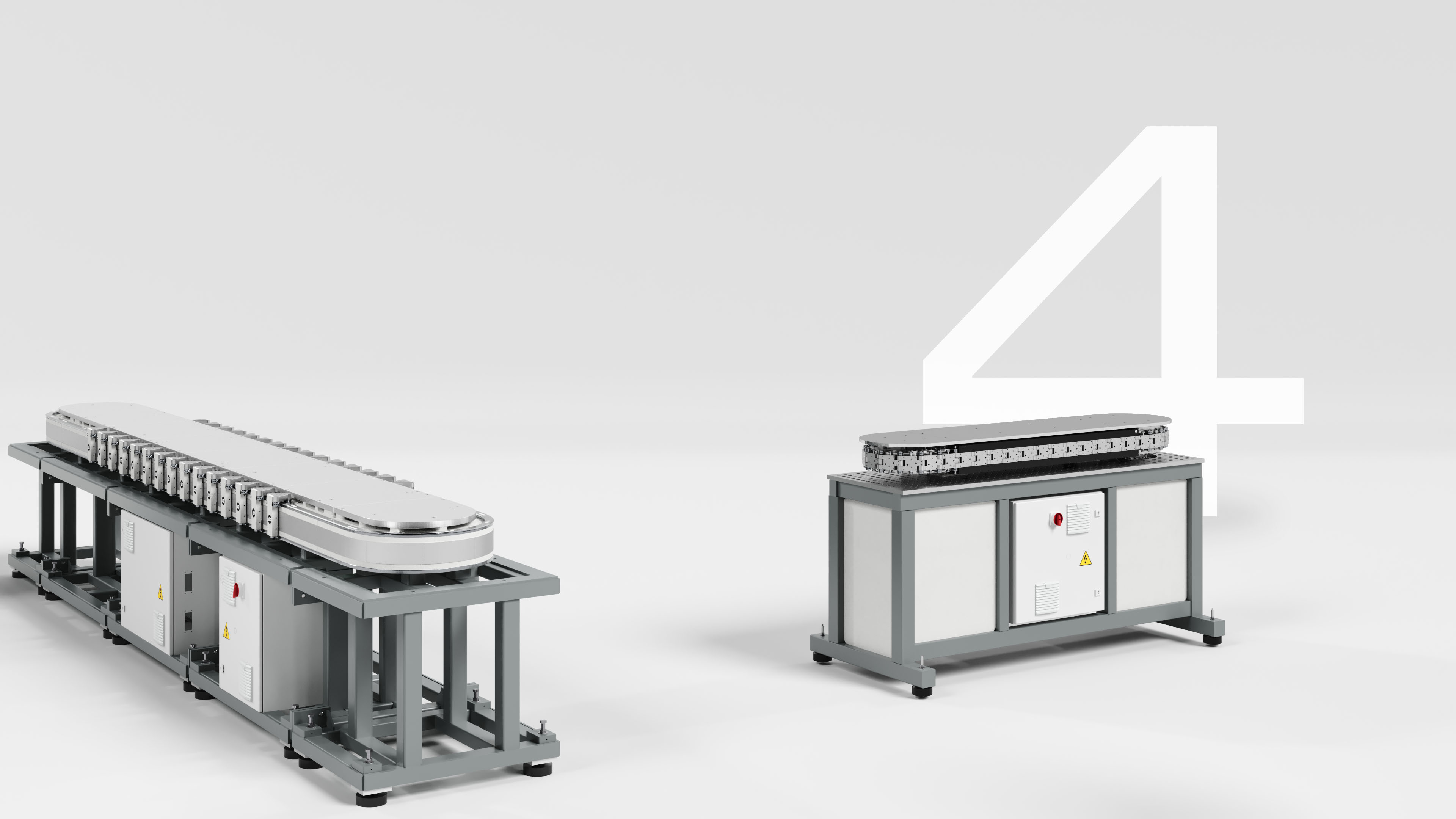

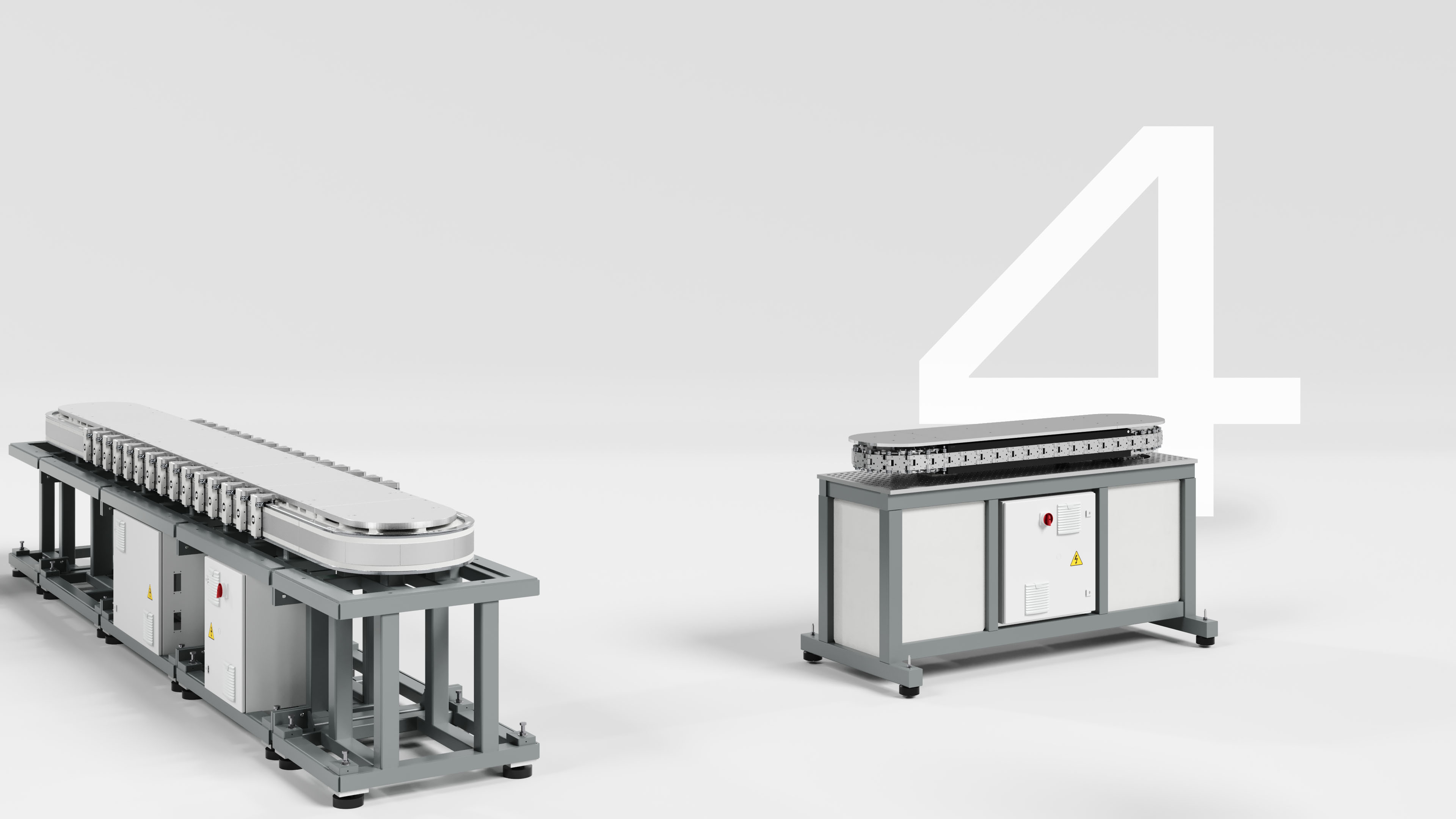

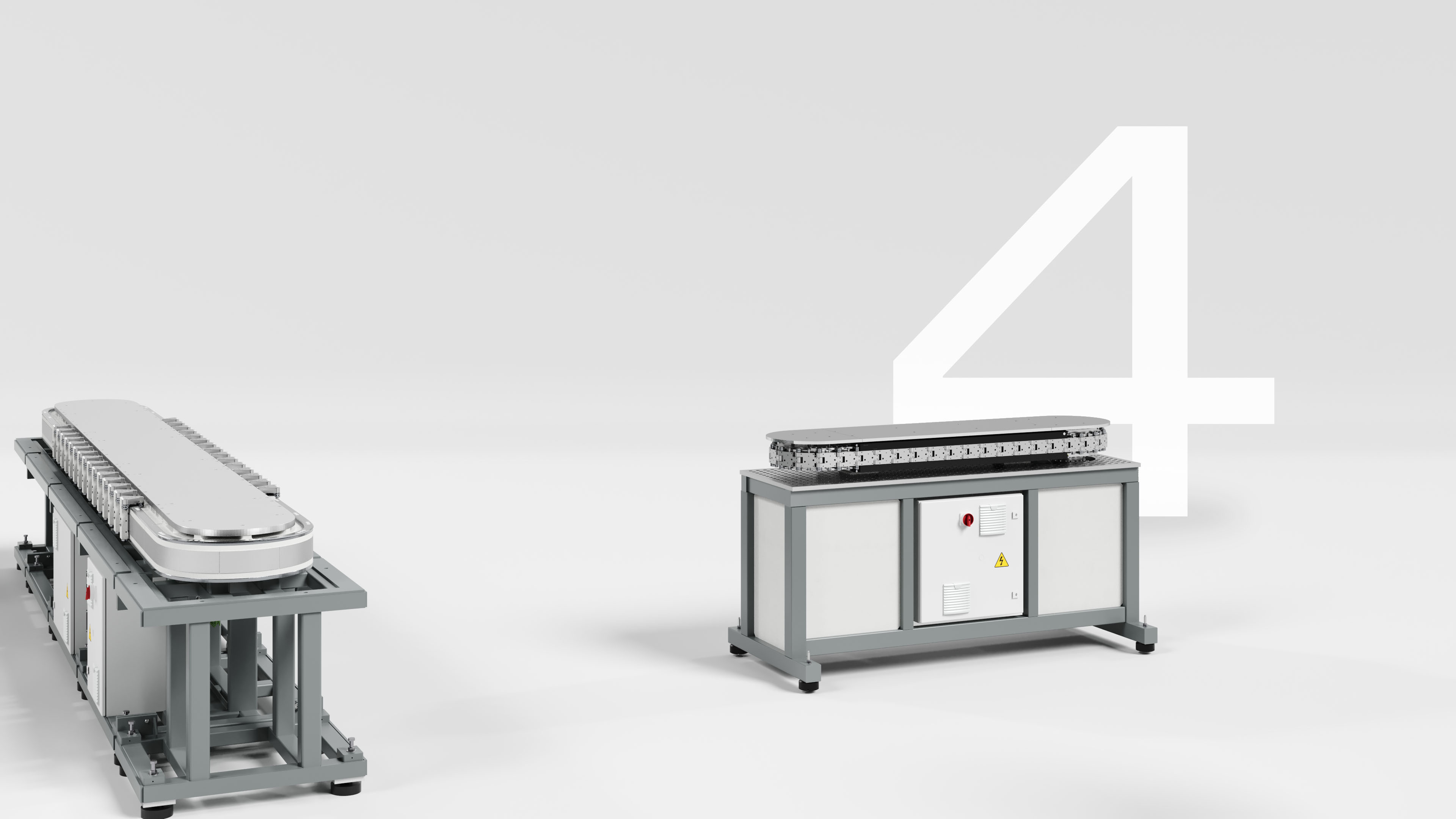

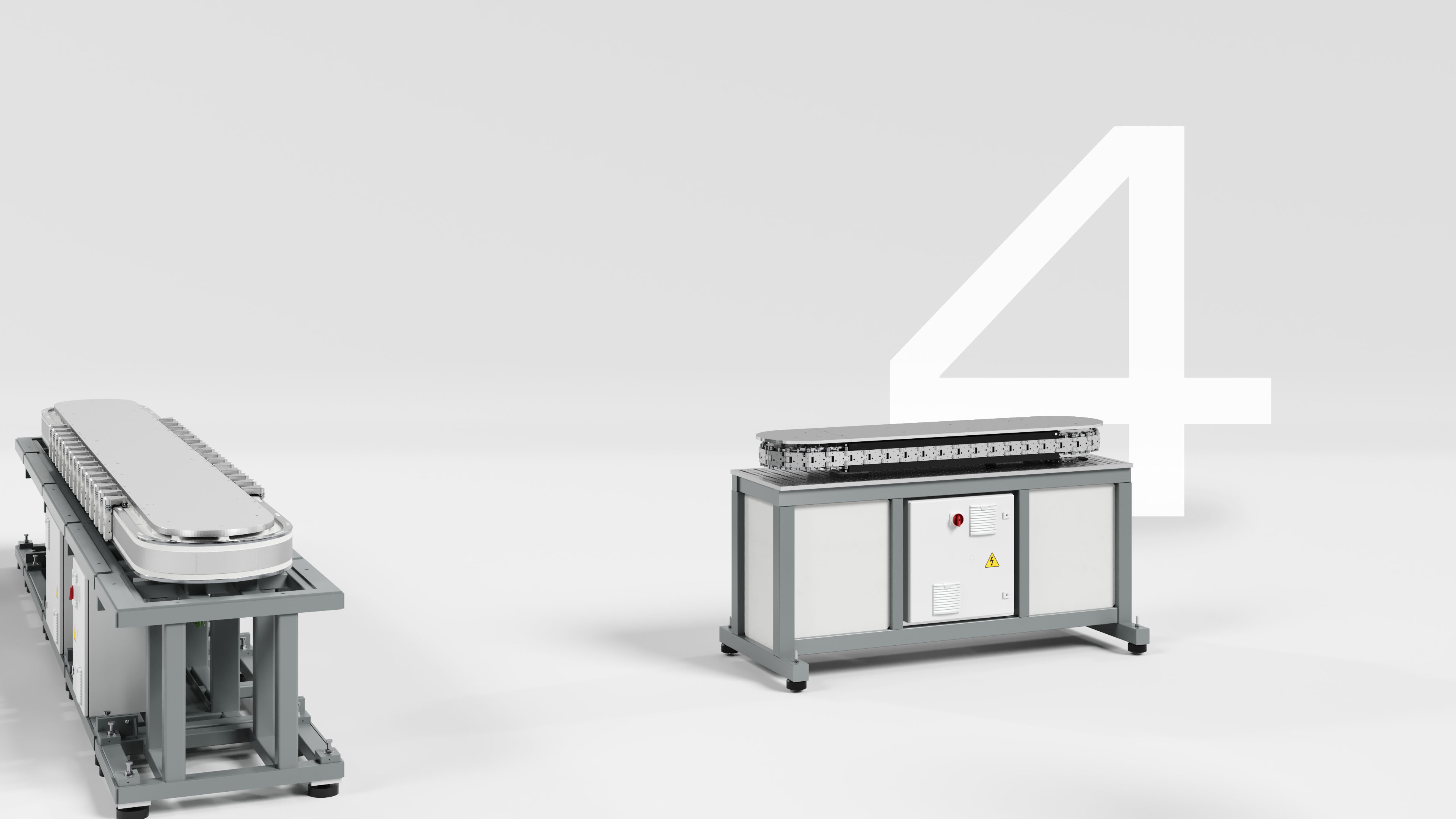

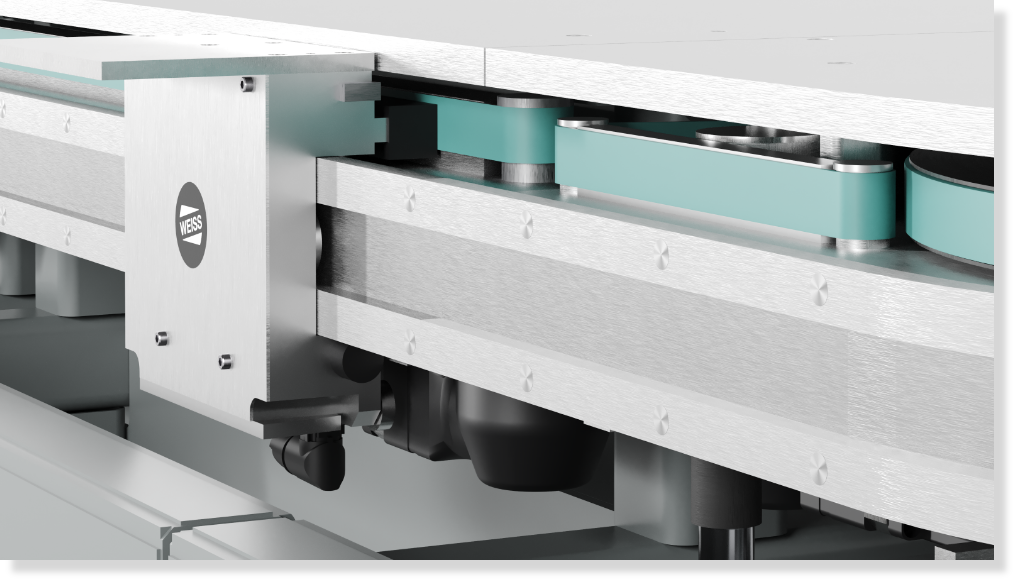

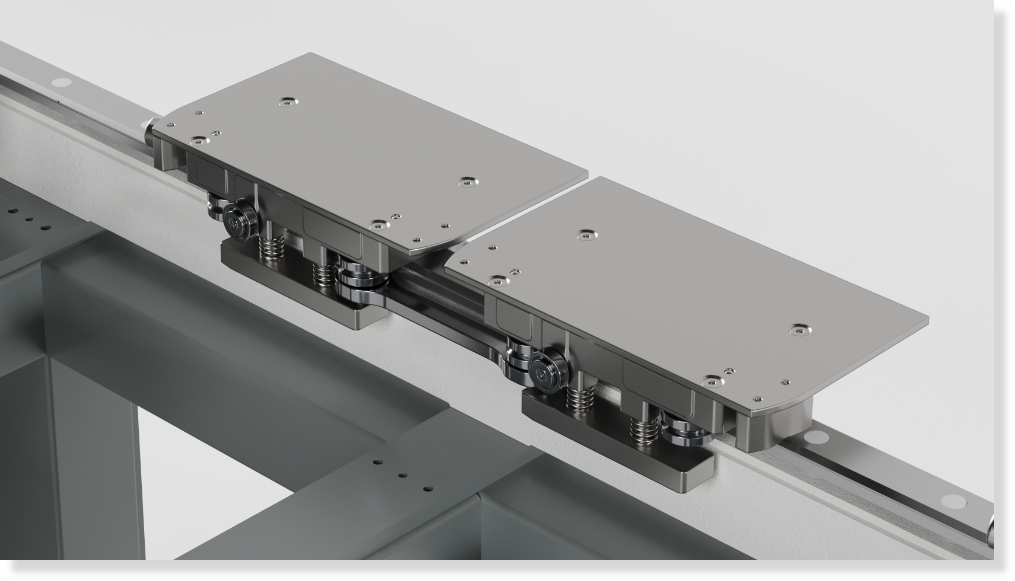

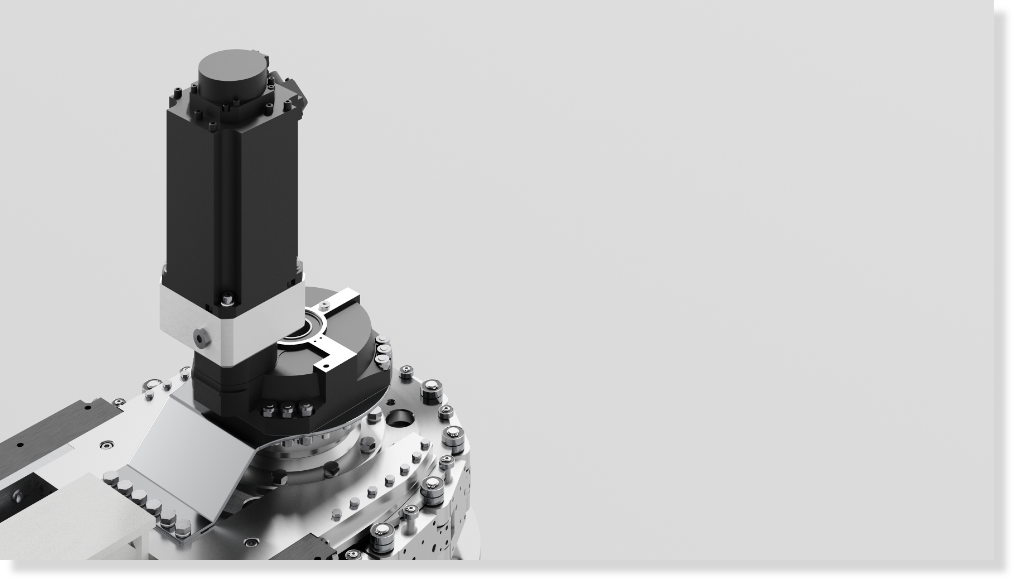

Linear transfer system

LS280

This LS System transfers the operating principle of the

Rotary Indexing Table to the straight section — including

an unlimited number of stop positions.

- Stable design

- High-quality control cabinets are available

- Handling components can be integrated without a substructure

- Standard – mounting plates of 660 x 485 x 25 mm,

optionally with customer's hole pattern

- Freely programmable position, acceleration, speed and movement direction

- Forward and reverse movements are possible

- Positioning accuracy of ± 0.05 mm in the x-direction and ± 0.03 mm in the y- and z-directions

- Short transport times

- Process forces up to 300 N without additional support

- Loading up to 2 kg (weight of workpiece + its holders)

- Customer-supplied plates with a max. length up to 200 mm

- Optionally with RFID transponder

- Hardware capable of multiple voltages (400/480 V 3ph / 50/60 Hz)

- Fieldbus interfaces for customer interface:

Profinet, Ethernet/IP, EtherCAT - Frequency converter with integrated restart interlock Safe Torque Off (SIL 3, PL "e"), no SLS, no SOP

- 60% shorter transport times

- More processes in less space

- Tried-and-tested linear motor drive

- Payload up to 10 kg (weight of workpiece + its holders)

- Absolute locking without indexing

- Process forces up to 1000 N without support

- Standard – carrier plates of 200 x 160 mm to a max. of 250 x 235 mm, optionally with customer's hole pattern

- Optionally with RFID transponder

- Positioning accuracy of ± 0.03 mm in x-, y- and z-directions

- Strokes: 64, 128, 256, 384, 512 mm

- Short transport times

- Up to nine eCAMs can be connected in series in one drive module

- Freely programmable position, acceleration, speed and movement direction

- Positioning accuracy ± 0.02 mm (x-direction)

± 0.03 mm (y- and z-directions) - Short transport times

- Forward and reverse movements are possible

- Single-belt (1 x 1150 mm) or double-belt module (2 x 575 mm) available

- Positioning accuracy of ± 0.15 mm in the x-direction and ± 0.03 mm in the y- and z-directions

- Stop position in the center of the belt is possible

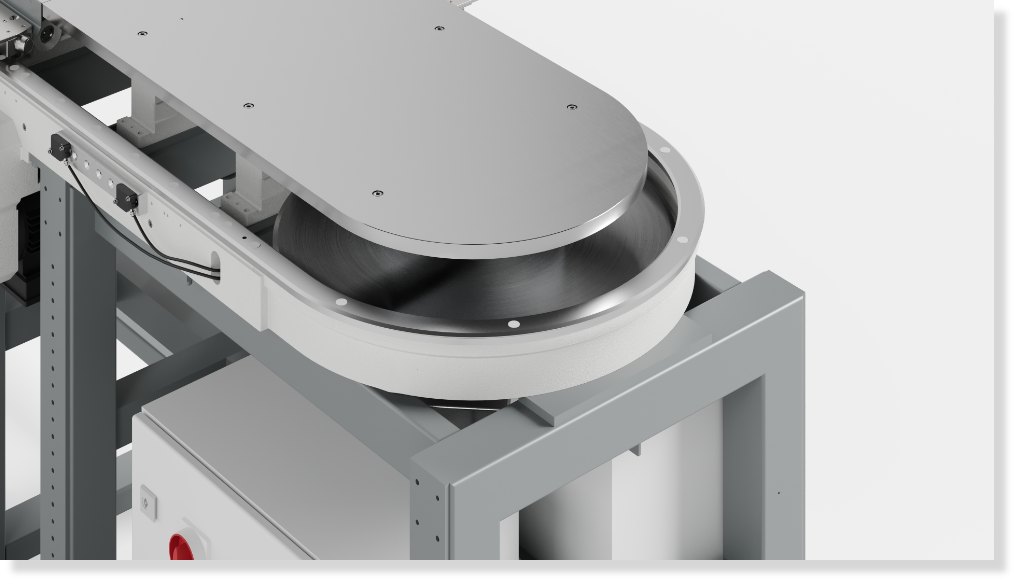

- Consists of 3 belts, redirection belt and infeed belt and outfeed belt

- Smoothly moves into/out of the straight transport modules

- 1 stop position at 90° is possible, positioning accuracy of ± 0.15 mm in the x-direction and ± 0.03 mm in the y- and z-directions

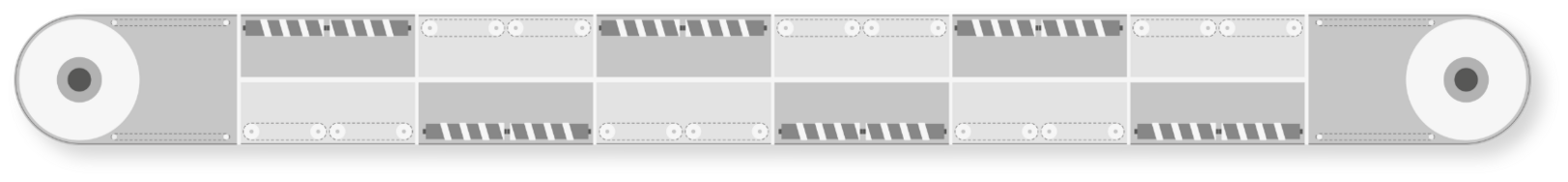

- Stable design

- Handling components can be integrated without a substructure

- High-quality control cabinets are available

- Standard – mounting plates of 1150 x 294 x 20 or 1150 x 590 x 20 mm, optionally with customer's hole pattern

- 20% higher cycle rates

- 40% shorter transport times

- High process capability

- More processes in less space

- Reliable components

- Hardware capable of multiple voltages (400/480 V 3ph / 50/60 Hz)

- Fieldbus interfaces for customer interface:

Profinet, Ethernet/IP, EtherCAT - Frequency converter with integrated restart interlock Safe Torque Off (SIL 3, PL "e"), no SLS, no SOP

- Positioning accuracy of ± 0.03 mm in the x- and y-directions and ± 0.06 mm in the z-direction

- Different strokes (70, 140, 280, 560 mm)

- Short transport times

- Available as a single or double locking station

- Up to 28 locking stations on one LS 280 are possible

- Available in different lengths and transport speeds

- Workpiece also accessible from underneath

- Loading up to 4 kg (weight of workpiece + its holders)

- Stationary support of the carrier plates is possible at high process forces

- Standardized carrier plates available in three sizes, optionally with customer's hole pattern

- Optionally with RFID transponder

- Stable design

- Handling components can be integrated without a substructure

- Central lubrication unit is optional

- Standardized carrier plates available in three sizes, optionally with customer's hole pattern

- Standard mounting plates are 1199 x 320 mm and 1199 x 480 mm, optionally with customer's hole pattern

- Available in two versions

- 180° redirection module for a linear design

- 90° redirection module so that the face ends can have process stations attached

- Higher cycle rate increases the output

- Simple, reliable motion principle

- Workpiece carrier transport optimized for low level of jerking and jolting

- Compensates for different process times

- Highly reliable thanks to maintenance-free operation

- One master PLC per LS280 base machine

- Centrally stored parameter file

- Fieldbus interfaces for customer interface:

Profinet/Profibus, EtherNet/IP, EtherCAT - Hardware capable of multiple voltages (400/480 V 3ph / 50/60 Hz)

- Frequency converter with integrated restart interlock Safe Torque Off (SIL 2, PL "d")

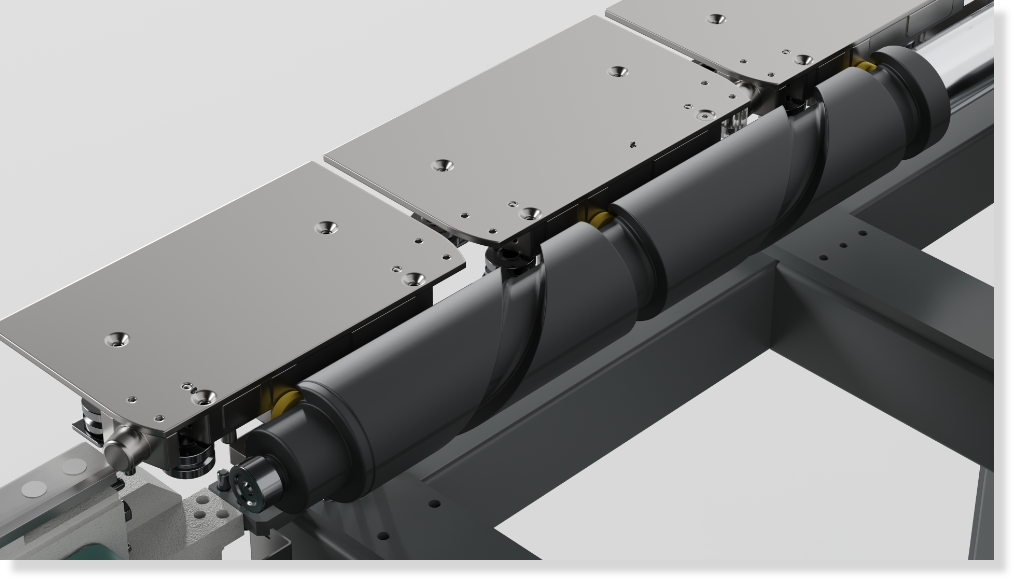

- Compact design

- Process stations in the drive module and redirection module are possible

- Higher weights in the horizontal position are possible

- Chain is easy to assemble and lengthen

- Changing products is easy

- Use of standard components for high availability

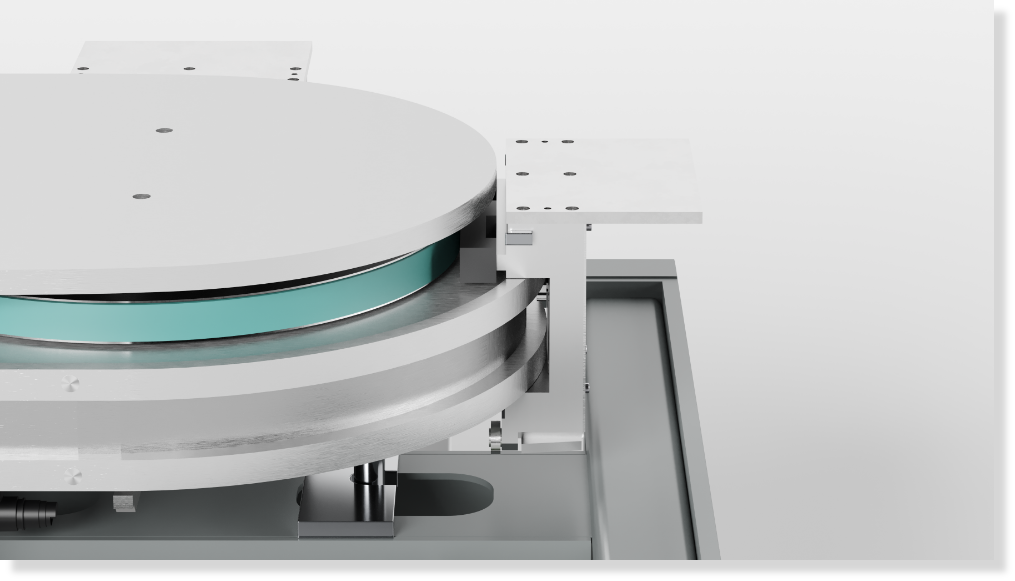

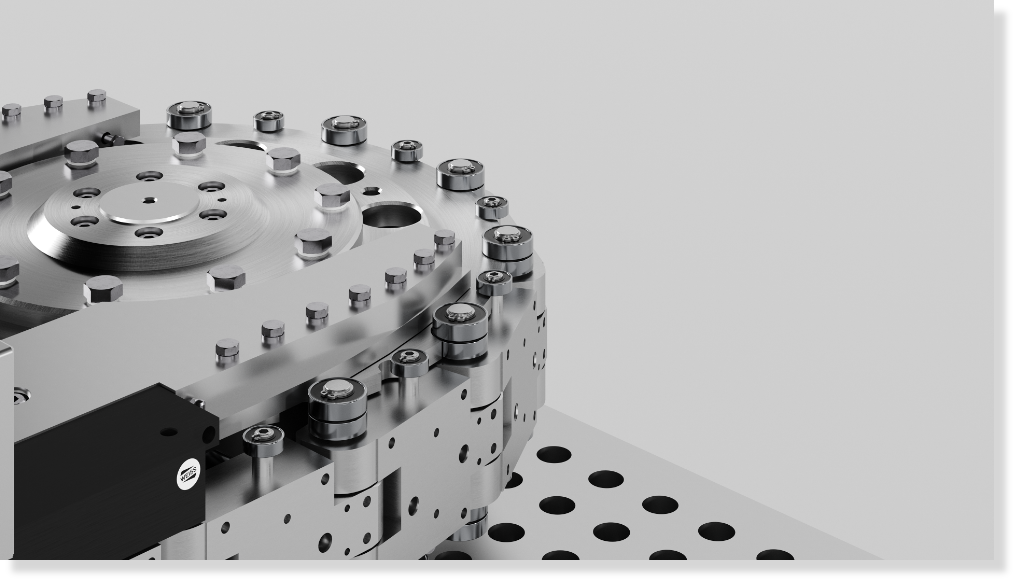

- High-efficiency gear unit for maximum efficiency

- Patented wear compensation

- Long service life

- Low breakaway torque

- High input torque and input speed

- One standard frame for all variants

- Easy integration, e.g. of robot bases

- Placement of process stations inside and outside

- Integration of additional handling units

- Preprogrammed control package

- Finished parameter sets

- Easy start-up

- Plug & work principle

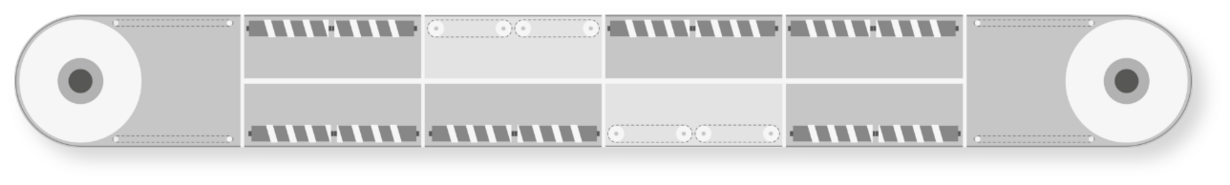

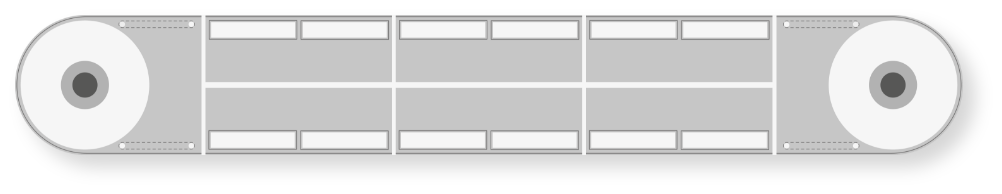

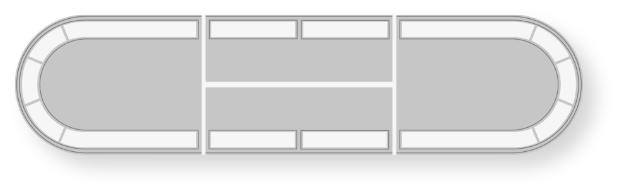

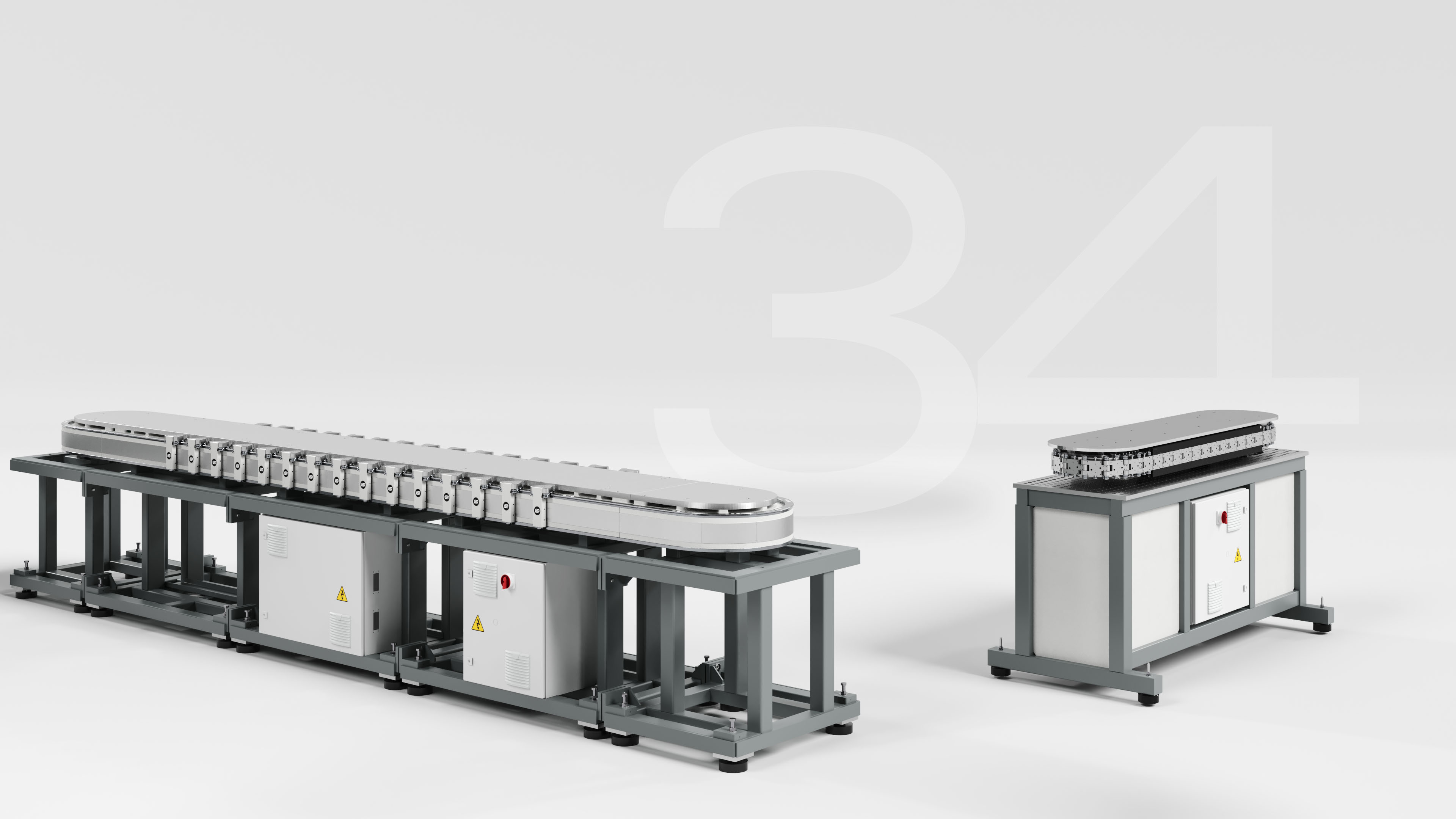

Linear transfer system

LS HYBRID

Whether a cam drive in combination with a belt section

or a direct drive in combination with a belt section — the

hybrid drive system allows for adaptation to individual

application requirements.

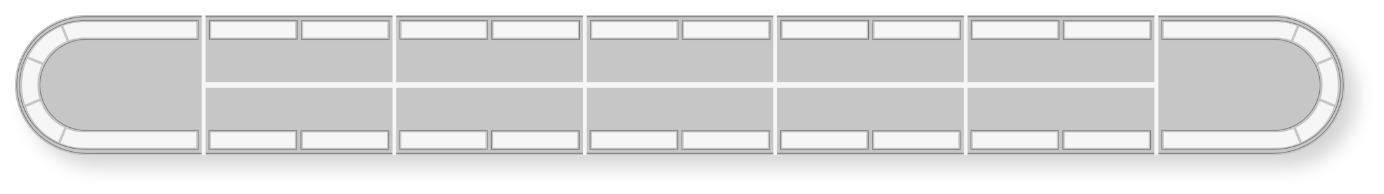

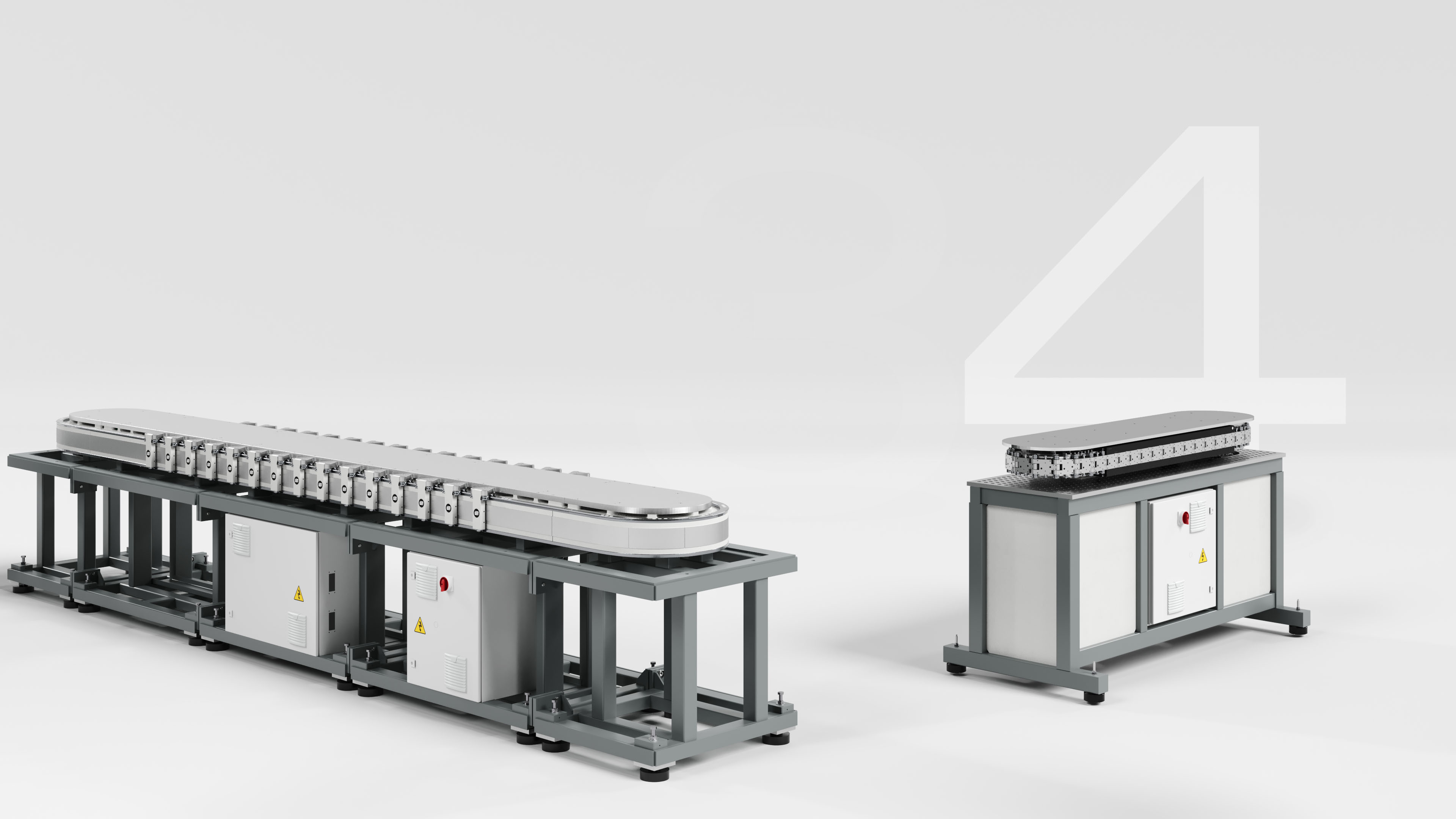

Linear transfer system

LS ONE

Even shorter processes and faster transport times.

About 70 cycles/min are guaranteed with the LS One —

as with all LS Systems with the plug & produce

mentality.